Split contact support and contactor

A contact-supported, split-type technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems such as room for improvement and large noise in the buffering effect, and achieve the goal of controlling material costs, reducing working noise, and reducing noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

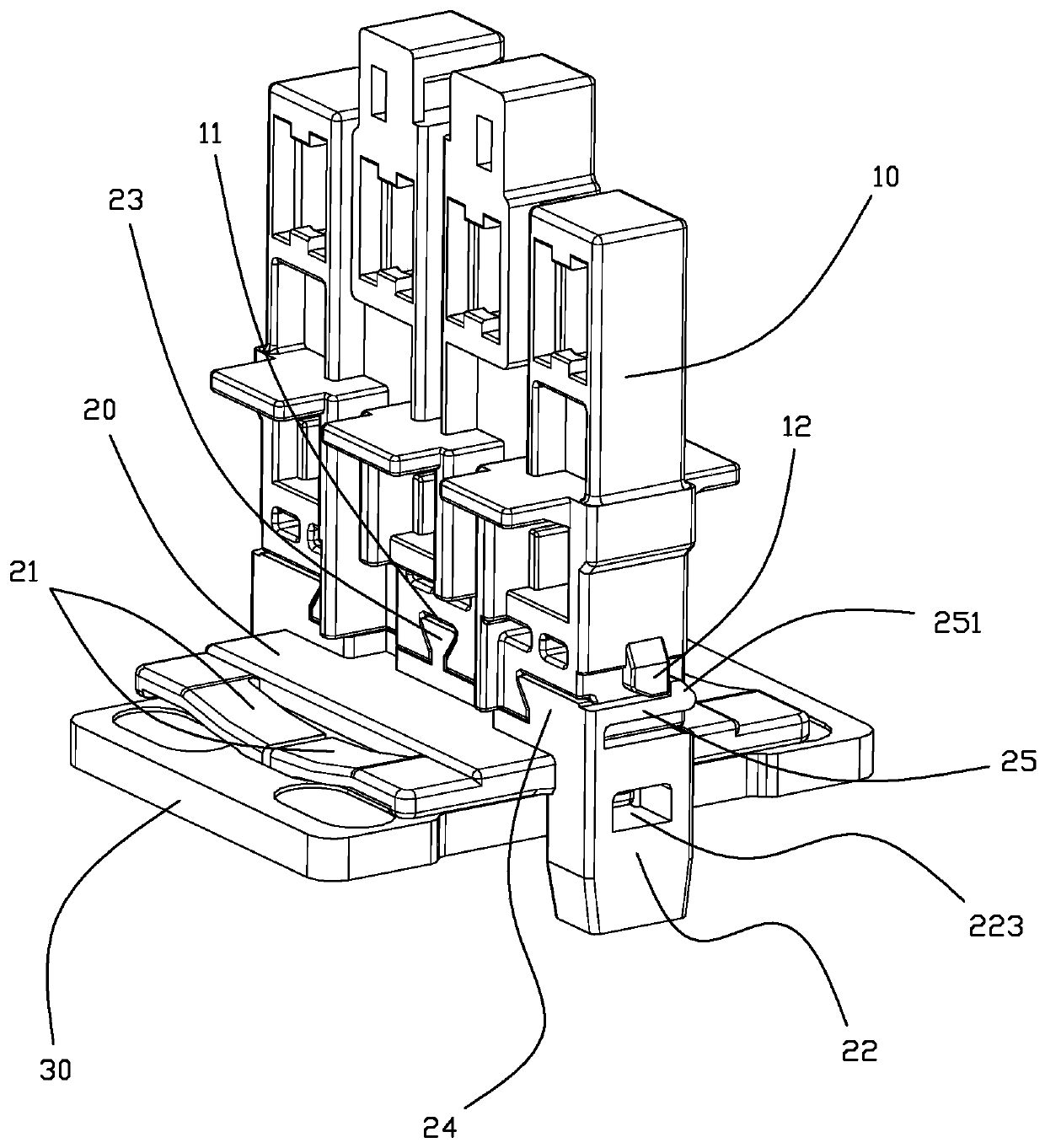

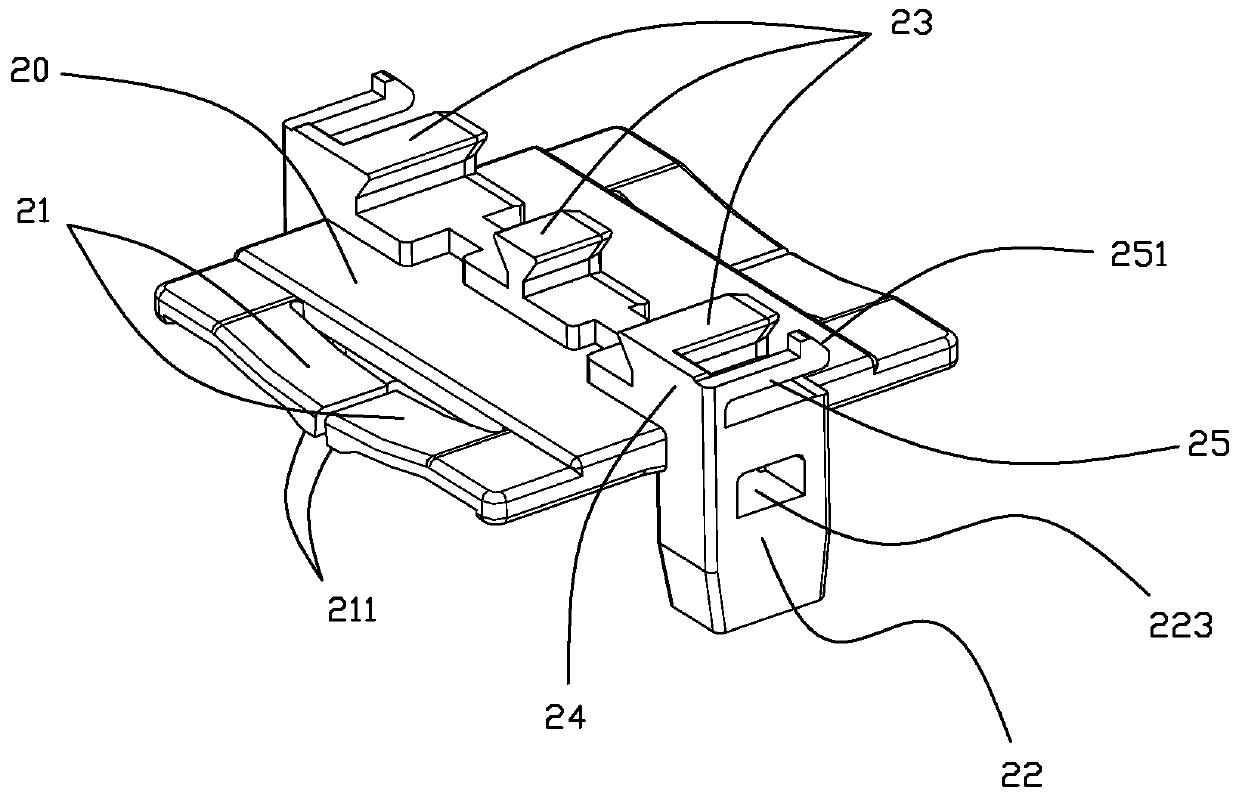

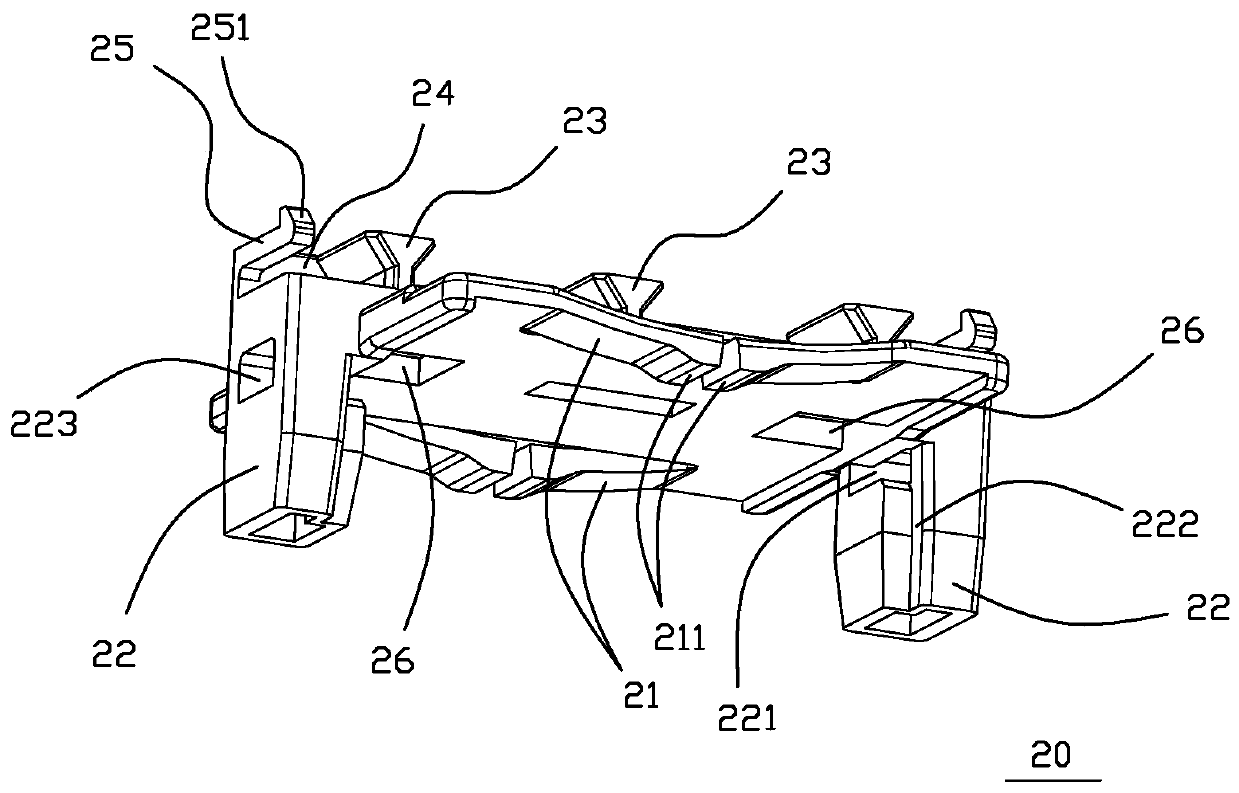

[0042] In order to solve the problems in the prior art that the material cost and life requirements cannot be balanced, poor buffer performance of the armature, high working noise, and low connection strength of the armature, the present invention provides a split-type contact support, and the support assembly is set as an independent The contact support part and the support connecting plate are used to select different materials, control the material cost at the same time, and meet the life requirements, and achieve the optimal balance between material cost control and life requirements; and improve the buffer performance of the armature, reduce Working noise when the contactor operates. The present invention provides a contactor based on the split-type contact support, similarly, it can control the material cost, meet the service life requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com