A kind of alkaline hydroxyphenazine organic liquid flow battery and its preparation method

A technology of hydroxyphenazine and liquid flow battery, which is applied in the field of electrochemical energy storage, can solve the problem of high decay rate of the negative electrode, and achieve the effect of good voltage adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An alkaline hydroxyphenazine organic liquid flow battery, the preparation method of which is as follows:

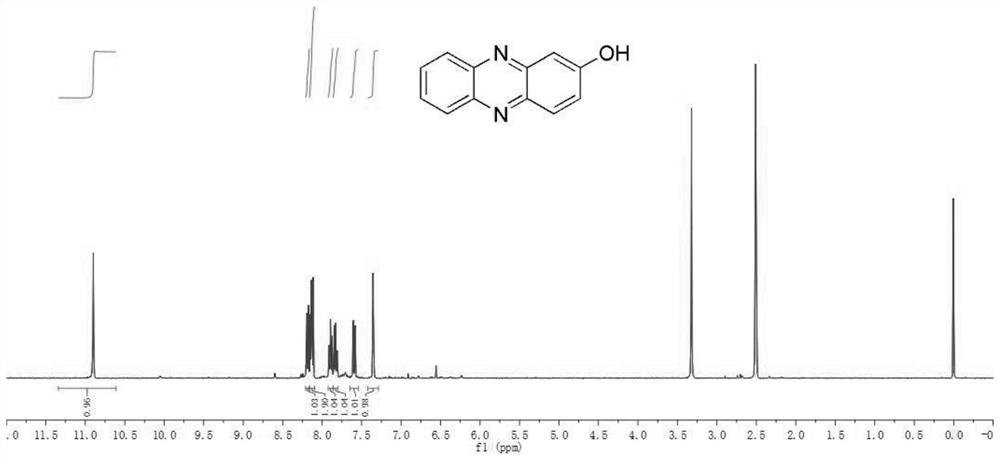

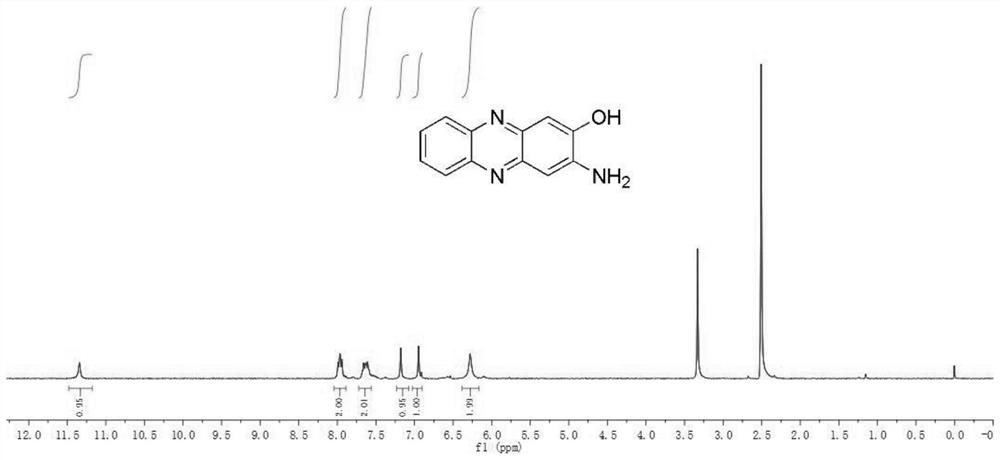

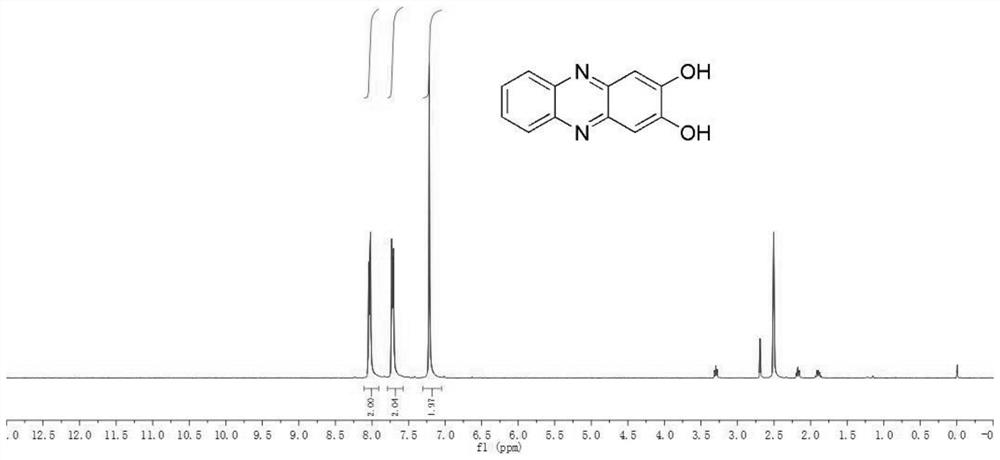

[0046] like Figure 1-4 As shown, the preparation of hydroxyphenazine is as follows:

[0047] The benzoquinone and its derivatives and o-phenylenediamine are reacted with absolute ethanol as a solvent in a low temperature environment for 2-12 hours. After the reaction, a large amount of water is added for filtration, and the filter cake is collected and dried to obtain HP and its derivatives.

[0048]The o-phenylenediamine and its derivatives are reacted with ammonium persulfate as a catalyst and water as a solvent for 12-48 h, after the reaction is completed, an alkali solution is added for filtration, the filtrate is collected, and the pH of the filtrate is adjusted so that the AHP and its derivatives in the filtrate are as After the solid is precipitated, suction filtration, the filter cake is collected, and then dried to obtain AHP and its derivatives.

[004...

Embodiment 2

[0061] An alkaline hydroxyphenazine organic liquid flow battery, the preparation method of which is as follows:

[0062] The preparation of hydroxyphenazine is as follows:

[0063] The benzoquinone and its derivatives and o-phenylenediamine were reacted with absolute ethanol as a solvent in a low temperature environment for 8 hours. After the reaction, a large amount of water was added for filtration, and the filter cake was collected and dried to obtain HP and its derivatives.

[0064] The o-phenylenediamine and its derivatives are reacted with ammonium persulfate as a catalyst and water as a solvent for 24 hours. After the reaction is completed, an alkaline solution is added for filtration. After suction filtration, the filter cake is collected, and then dried to obtain AHP and its derivatives.

[0065] 2,5-dihydroxybenzoquinone and its derivatives and o-phenylenediamine and its derivatives are refluxed in an aqueous solution for 18 hours. After the reaction is completed, w...

Embodiment 3

[0072] An alkaline hydroxyphenazine organic liquid flow battery, the preparation method of which is as follows:

[0073] The preparation of hydroxyphenazine is as follows:

[0074] The benzoquinone and its derivatives and o-phenylenediamine were reacted with absolute ethanol as a solvent in a low temperature environment for 10 hours. After the reaction, a large amount of water was added for filtration, and the filter cake was collected and dried to obtain HP and its derivatives.

[0075] The o-phenylenediamine and its derivatives are reacted with ammonium persulfate as a catalyst and water as a solvent for 20 hours. After the reaction is completed, an alkali solution is added for filtration, the filtrate is collected, and the pH of the filtrate is adjusted so that AHP and its derivatives in the filtrate are precipitated as solid After suction filtration, the filter cake is collected, and then dried to obtain AHP and its derivatives.

[0076] 2,5-dihydroxybenzoquinone and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com