Resin hole plugging method for manufacturing 5G circuit board

A technology for circuit board manufacturing and resin plugging, which is used in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as holes that cannot be filled, air bubbles in holes, and affect physical health, and achieves cost saving and volatilization reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

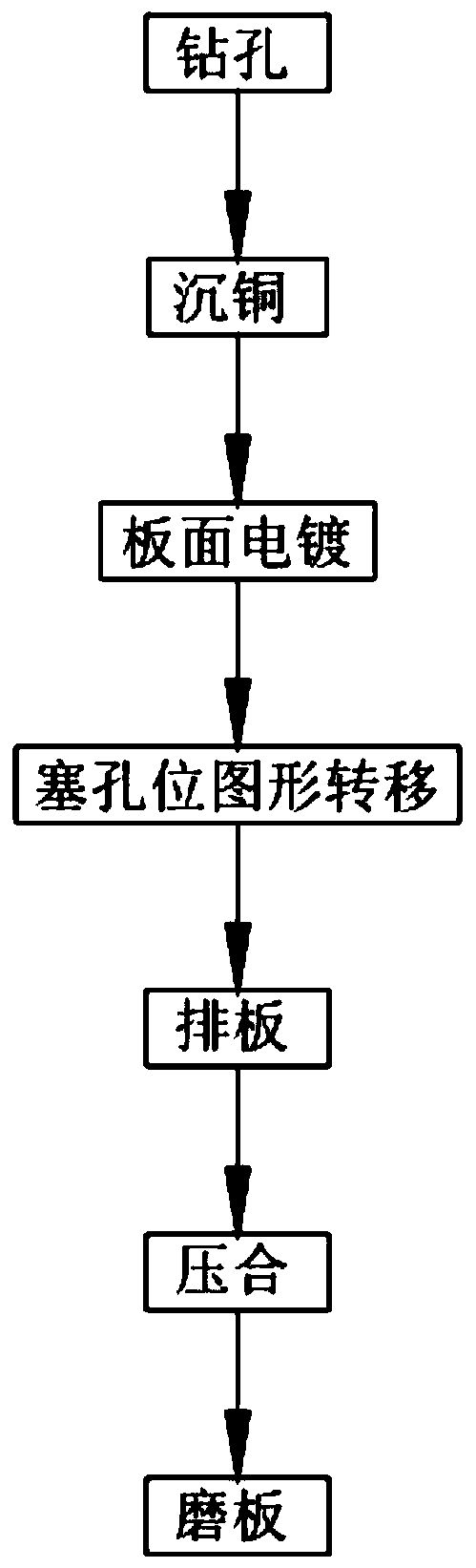

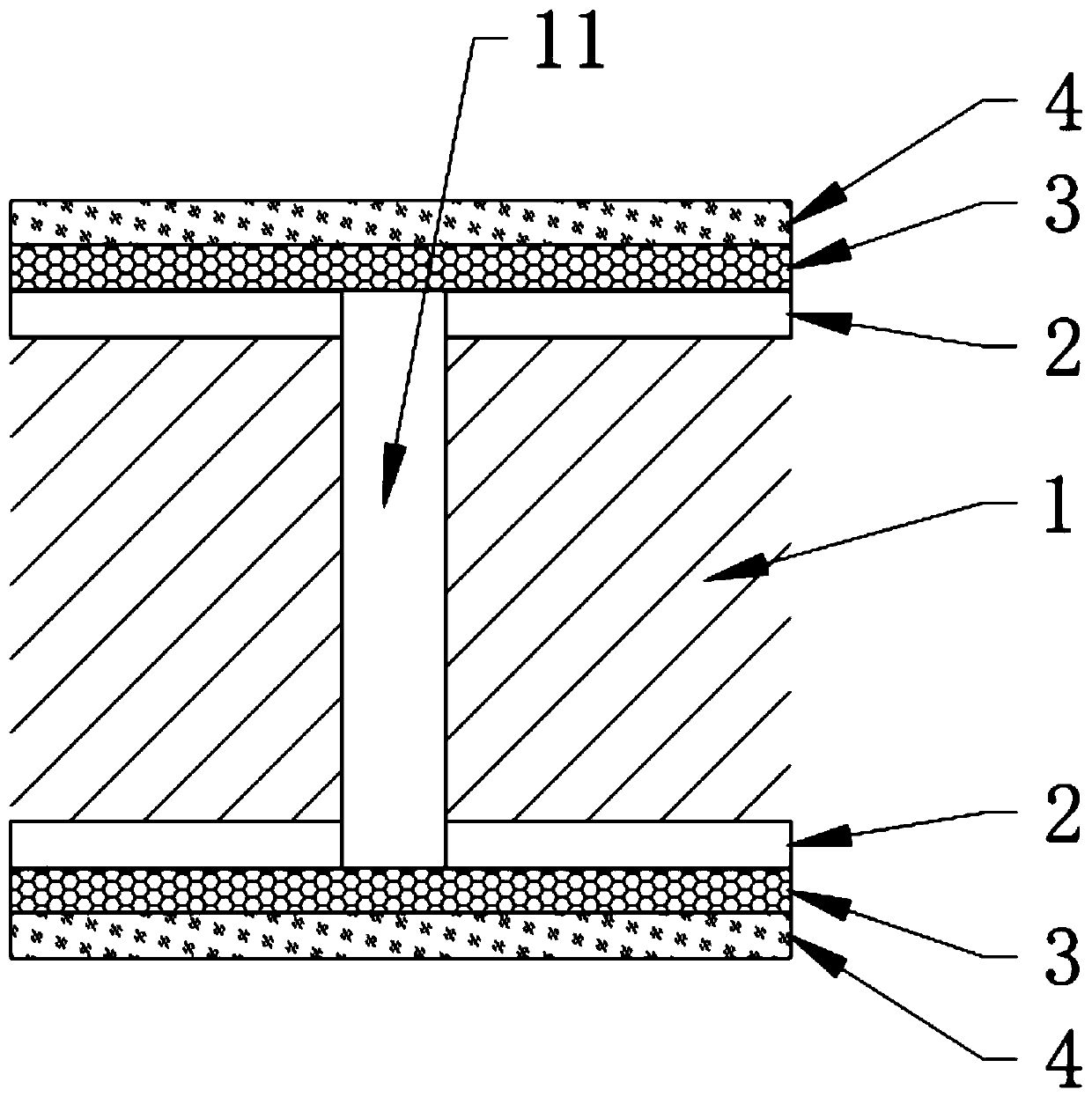

[0032] Please also refer to figure 1 and figure 2 , this embodiment includes the following steps:

[0033] Drilling: Drill holes on a circuit board with a thickness of 4mm and an aspect ratio of 20:1;

[0034] Copper sinking: decontaminate the circuit board first, then put the decontaminated circuit board into the copper sinking potion, and conduct preliminary copper sinking on the surface of the circuit board and the wall of the hole;

[0035] Board surface electroplating: the whole board is electroplated to obtain a conductive copper layer with a set thickness;

[0036] Plug hole pattern transfer: paste photosensitive film on both sides of the circuit board, the temperature resistance of the photosensitive film is 200°C, the speed of photosensitive film is 0.5m / min, and the film pressure is 1kg / cm 2 , the temperature of the film is 120°C, and then the circuit board covered by the photosensitive film is exposed and developed. 2 , The developing temperature is 35°C, wash ...

Embodiment 2

[0041] Please also refer to figure 1 and figure 2 , this embodiment includes the following steps:

[0042] Drilling: Drill holes on a circuit board with a thickness of 5mm and an aspect ratio of 25:1;

[0043] Copper sinking: decontaminate the circuit board first, then put the decontaminated circuit board into the copper sinking potion, and conduct preliminary copper sinking on the surface of the circuit board and the wall of the hole;

[0044] Board surface electroplating: the whole board is electroplated to obtain a conductive copper layer with a set thickness;

[0045] Plug hole pattern transfer: stick a photosensitive film on both sides of the circuit board, the temperature resistance of the photosensitive film is 200°C, the film sticking speed of the photosensitive film is 0.5m / min, and the film sticking pressure is 2kg / cm 2 , the temperature of the film is 130°C, and then the circuit board covered by the photosensitive film is exposed and developed. 2 , The developi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com