Rotary disc type automatic sand blasting mechanism

A technology of sandblasting machine and turntable type, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc., which can solve the problems of reducing the service life of equipment, reducing production efficiency, and damage to equipment and equipment, so as to prolong the service life , Eliminate safety hazards, avoid the effect of opening and closing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

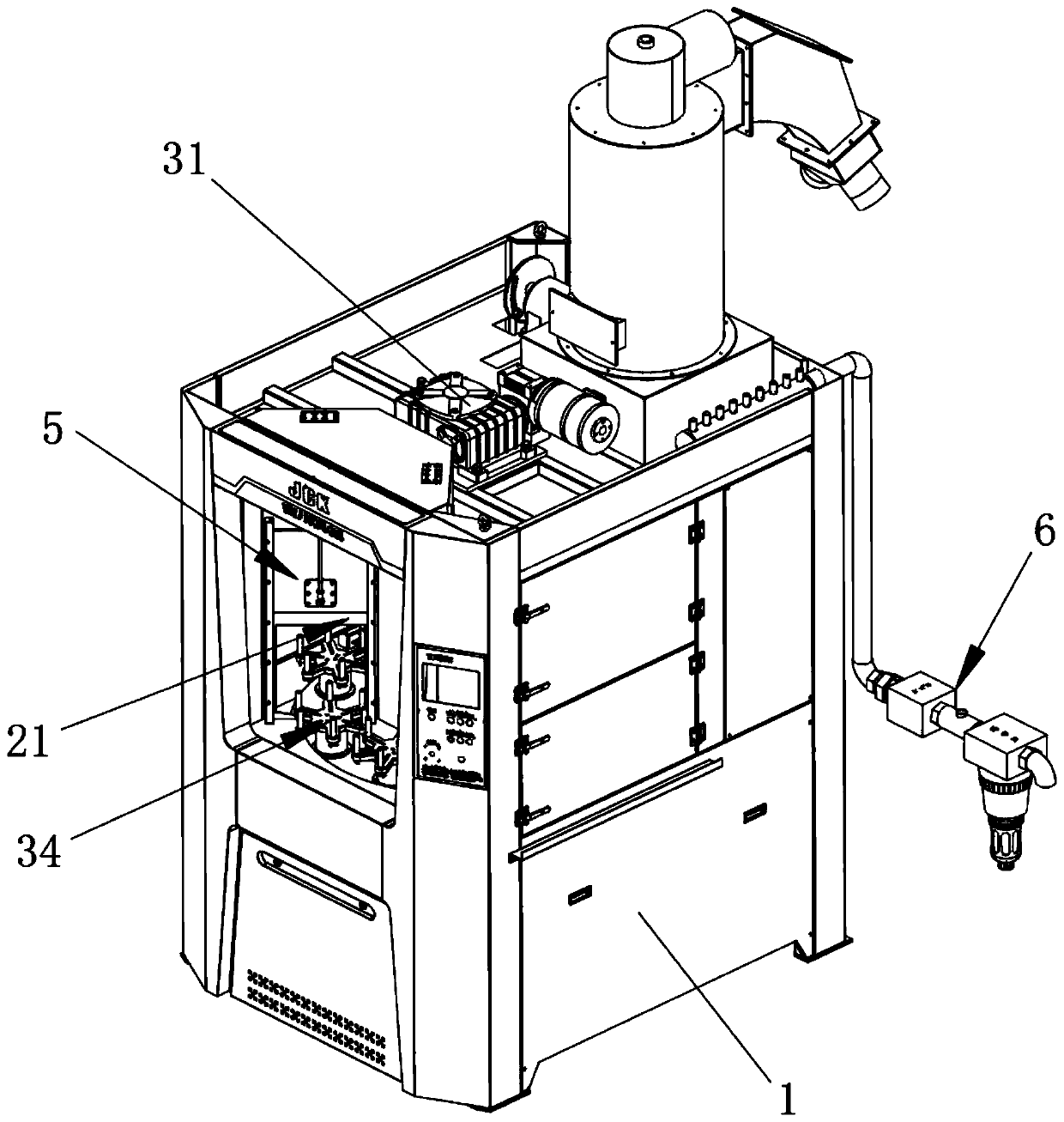

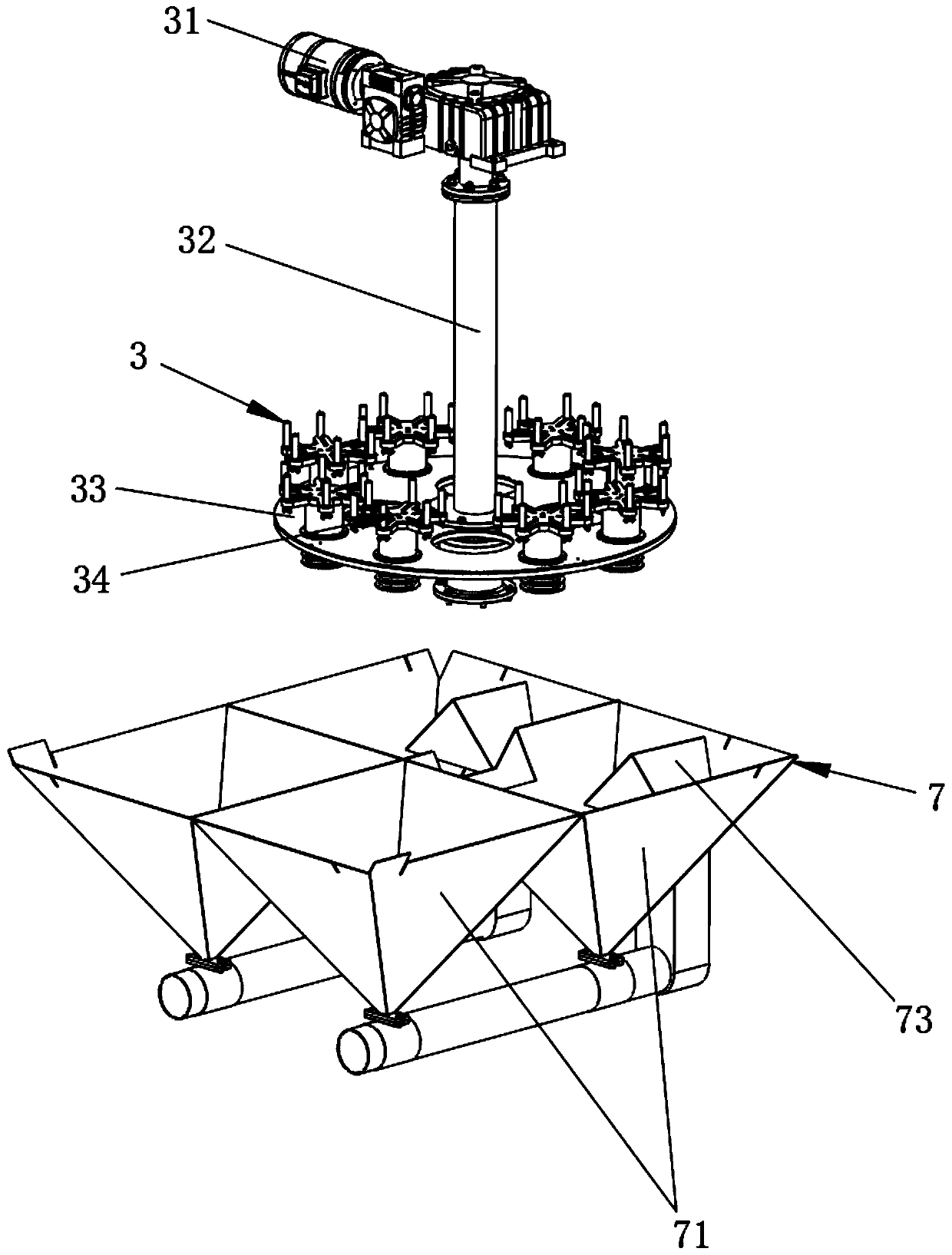

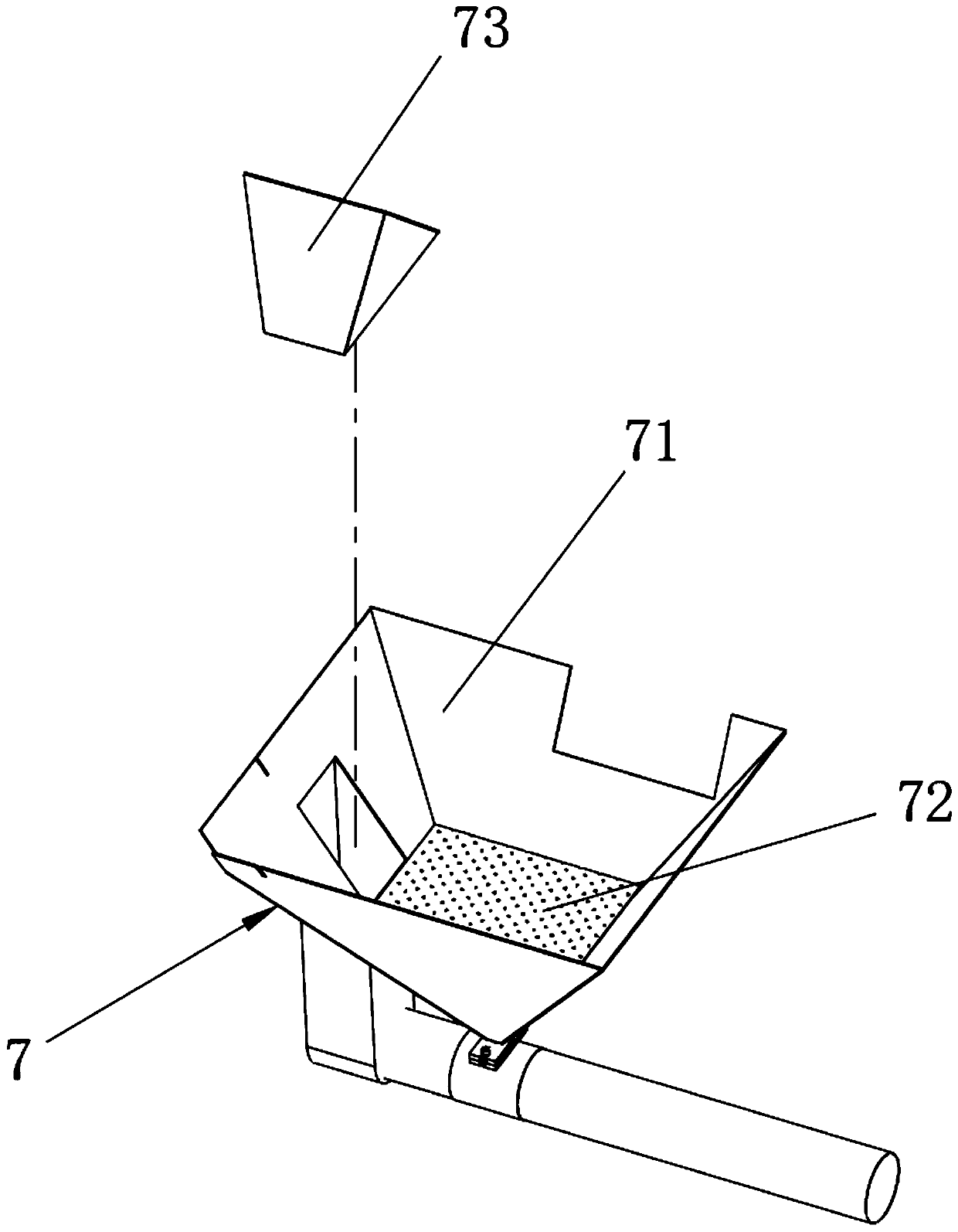

[0033] Such as Figure 1 to Figure 13As shown, a turntable type automatic sandblasting mechanism provided by the present invention includes a sandblasting frame 1, a sandblasting chamber 2 arranged in the sandblasting frame 1, and a sandblasting chamber 2 arranged in the sandblasting frame 1 for carrying workpieces. The turntable carrying device 3, the spray gun device 4 that is movable in the sandblasting room 2 and used for blasting the workpiece carried on the turntable carrying device 3, and the sandblasting device 4 that is set in the sandblasting room 2 and is used to prevent the spray gun device 4 from spraying The isolation device 5 for splashing materials everywhere, and the air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com