Preheating device and method for solving methyl alcohol standard exceeding in production process of fruit distillate liquor

A technology of production process and preheating device, applied in the field of fruit wine processing, can solve problems such as methanol exceeding the standard, and achieve the effects of facilitating mass production, reducing production costs, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

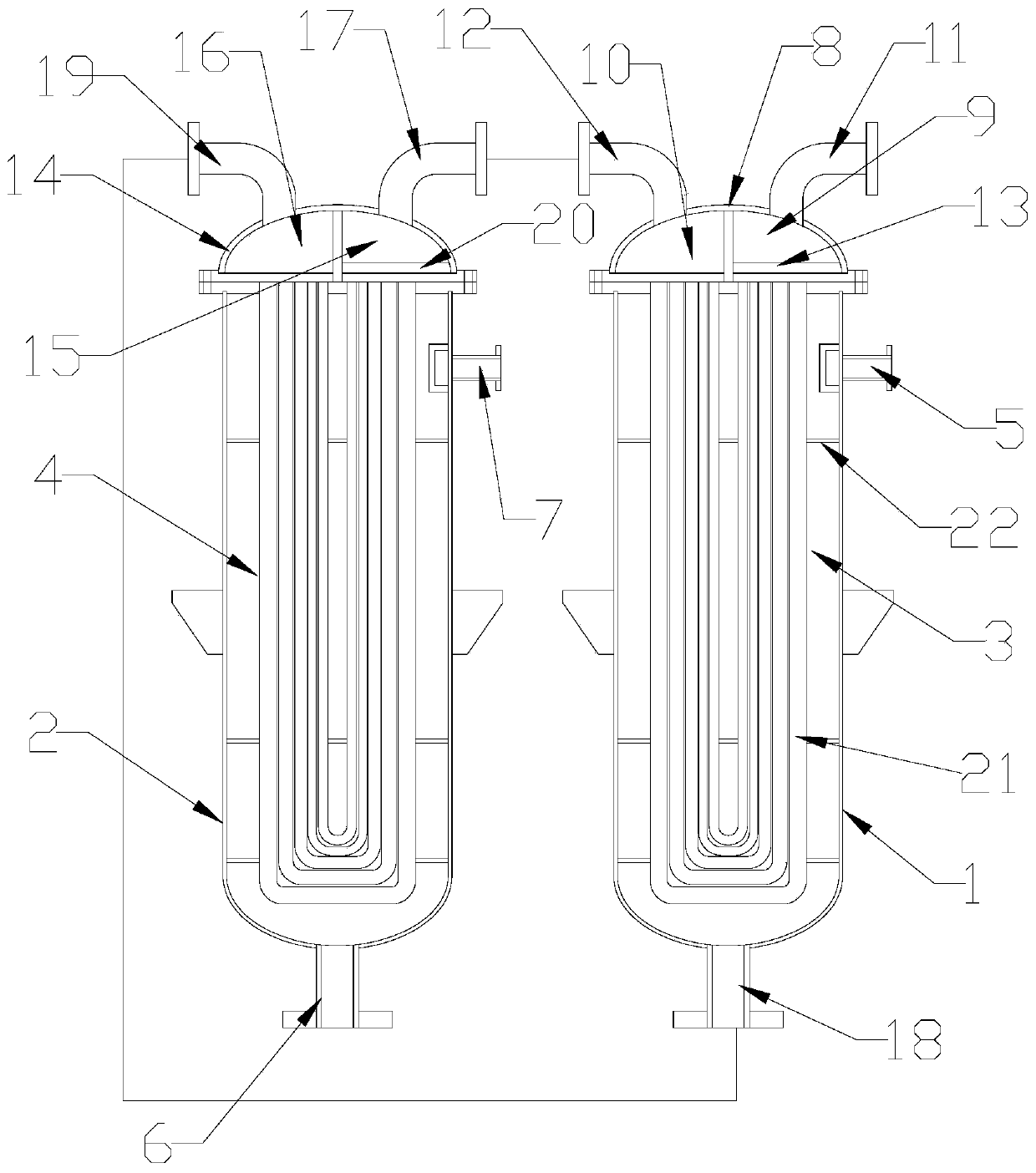

[0027] The preheating device for solving the problem of methanol exceeding the standard in the production process of fruit distilled wine includes a heat exchange box 1 and a heating box 2. The heat exchange box 1 is provided with a first coil assembly 3, and the heating box 2 is provided with a second coil assembly. The coil assembly 4, the outlet of the first coil assembly 3 communicates with the inlet of the second coil assembly 4, the outlet of the second coil assembly 4 communicates with the heat exchange box 1, and the heat exchange box 1 is provided with a third discharge pipe 5 for connecting with the fermentation device, and the feed port of the first coil assembly 4 is connected with the feed device. The lower end of the heating box 2 is provided with a first pipeline 6, and the upper end of the side wall of the heating box 2 is provided with a second pipeline 7. The second pipeline 7 is connected to a heating device. The heating device is a steam heating pipe, and ho...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, except that: a first temperature sensor is provided in the second discharge chamber 16 for monitoring the temperature of the high-temperature prefabricated solution; a second temperature sensor is provided at the third discharge pipe 5 A sensor for monitoring the temperature of the low-temperature prefabricated solution at the discharge port; a third temperature sensor is arranged in the heating box 2 for monitoring the temperature in the heating box 2; the first discharge pipe 12 and the second feed pipe 17 is provided with a solution flow meter and a first control valve, the second discharge pipe 19 is provided with a second control valve, the first feed pipe 11 is provided with a third control valve, and the third discharge pipe 5 A fourth control valve is arranged on the top, and the control valve is a solenoid valve or a manual valve.

Embodiment 3

[0034] The method of using the preheating device described in embodiment one and two to solve the problem of methanol exceeding the standard in the production process of fruit distilled wine comprises the following steps:

[0035](1) Crushing and beating the fresh fruit, adding pectinase and mixing evenly to obtain the initial solution of fruit pulp and pectinase; the initial solution of fruit pulp and pectinase enters the first feed chamber through the first feed pipe 11 9. In the first feeding chamber 9, enter the first coil through the first diverter plate 13, enter the second discharging chamber 16 through the discharge port of the first coil, and then pass through the first discharge pipe 12 and the second inlet Feed pipe 17 enters the second feed chamber 15, enters the second coil pipe through the second splitter plate 20 in the second feed chamber 15, starts the heating device and heats up, and initial solution is kept on suitable temperature, improves the activity of pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com