Molten iron dephosphorization device and method

A technology of molten iron and water inlet pipes, which is applied in the field of iron and steel smelting, which can solve the problems of many end point P deviations from the equilibrium value, long smelting time, and severe splashing, and achieve the effects of improving kinetic conditions, shortening smelting cycle, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

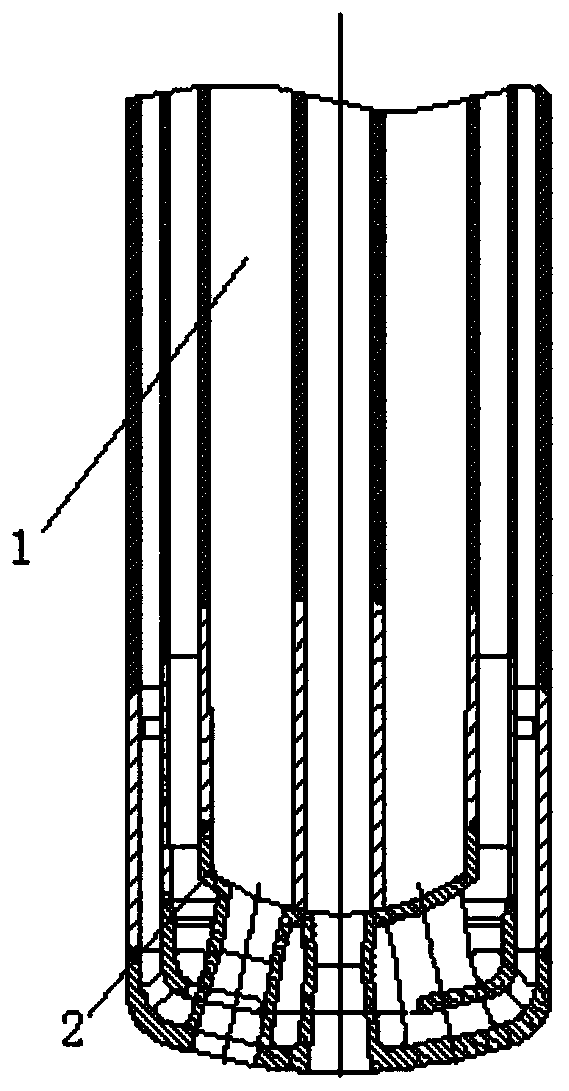

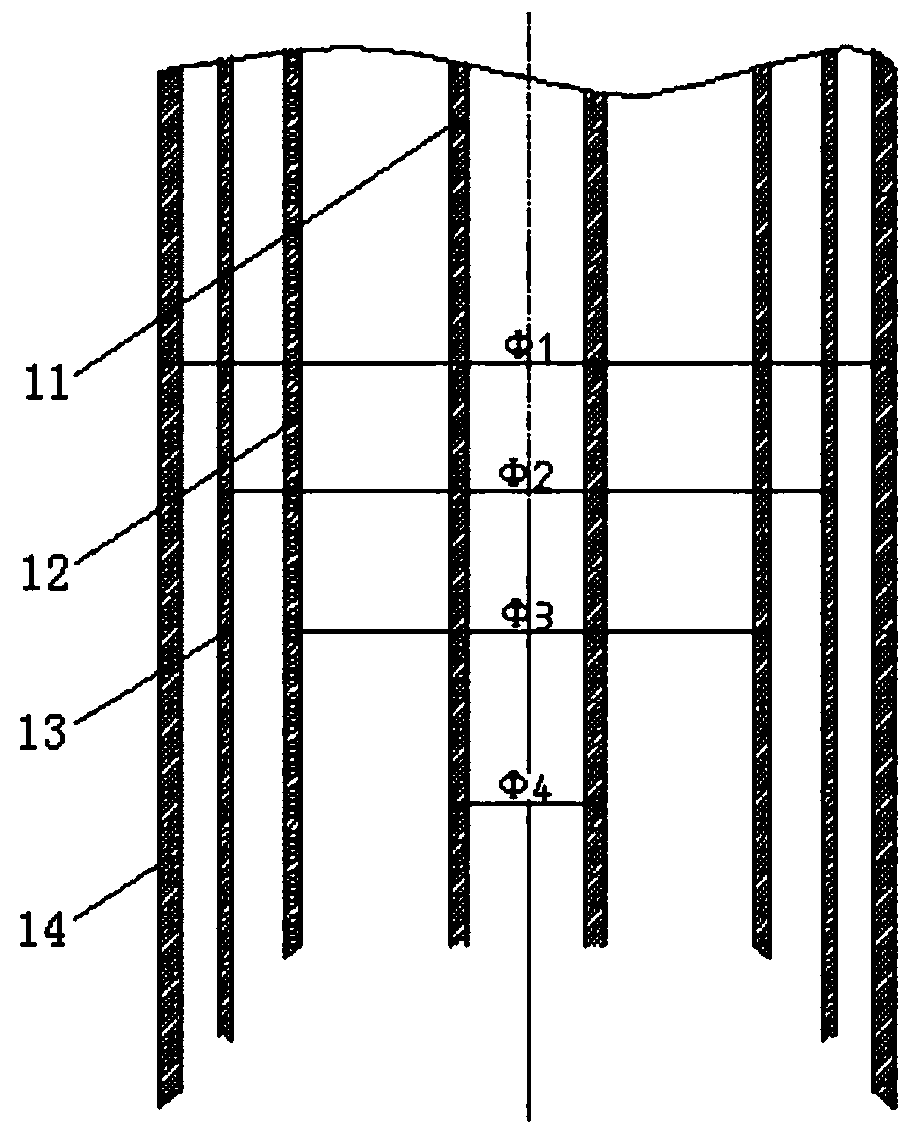

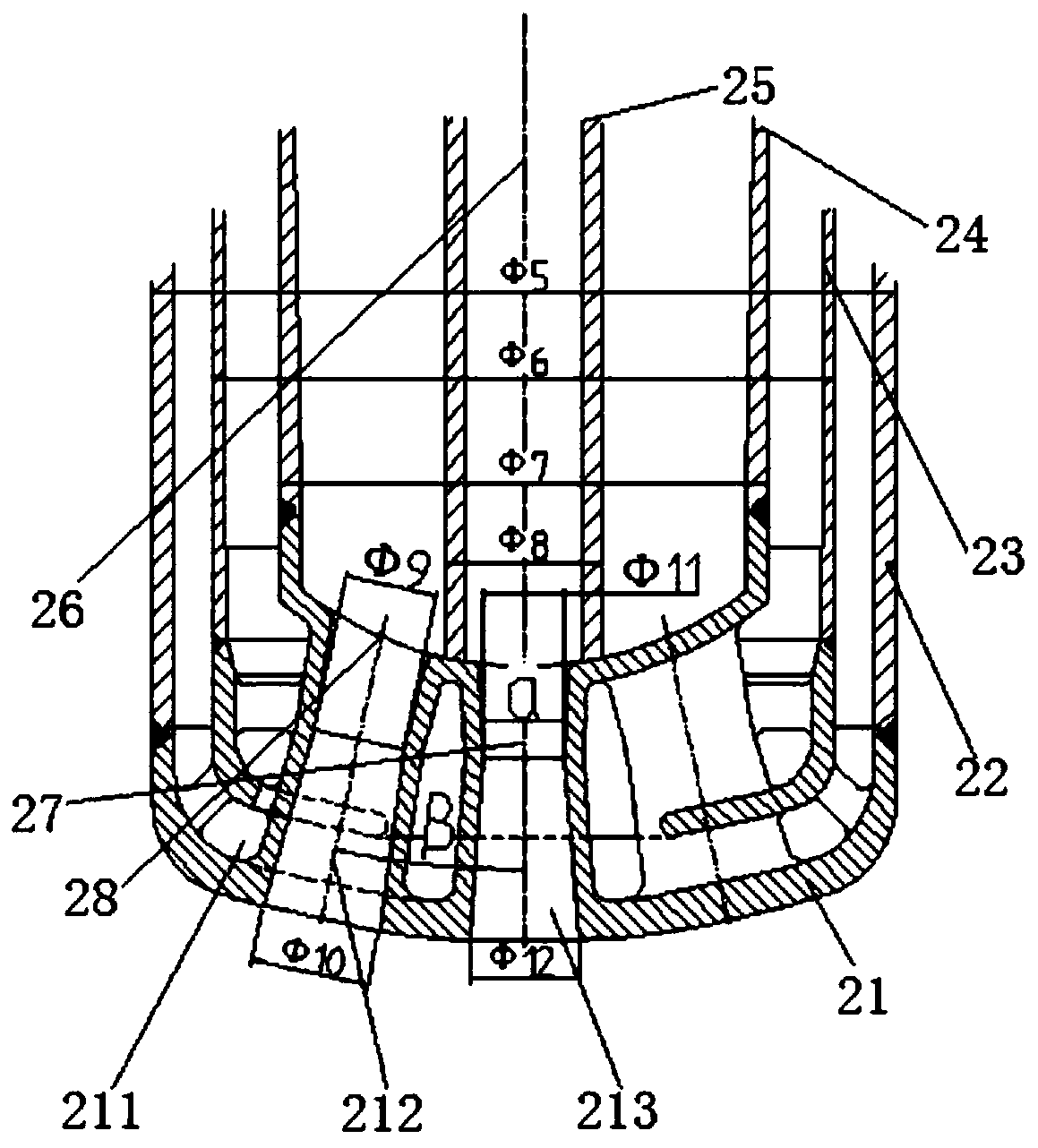

[0033] From Figure 1-3 It can be seen that a kind of molten iron dephosphorization device of the present embodiment includes a gun body assembly 1 and a nozzle assembly 2, and the gun body assembly 1 is composed of a gun body tube 11, a gun body intermediate tube 12, a gun body water inlet pipe 13 and a gun body assembly 1. The gun body return pipe 14 is composed of the gun body pipe 11, the gun body intermediate pipe 12, the gun body water inlet pipe 13 and the gun body return water pipe 14, which are coaxial cylinders, the gun body tube 11, the gun body intermediate pipe 12, the gun body The diameters of the water inlet pipe 13 and the gun body return pipe 14 are respectively denoted as Ф4, Ф3, Ф2 and Ф1, and the outer side of the inner tube 11 of the gun body is provided with a gun body intermediate pipe 12, and the outer side of the gun body intermediate pipe 12 is provided with a gun body water inlet pipe 13 , the outside of the gun body inlet pipe 13 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com