Pile body pneumatic reinforcement method

A pile and gas technology, applied in soil protection, protection devices, buildings, etc., can solve the problems of easy failure, insufficient storage capacity, poor corrosion resistance of pumps, etc., to prevent safety accidents and environmental pollution, acid resistance, etc. The effect of strong alkali salt and oxidizing ability, and strong operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

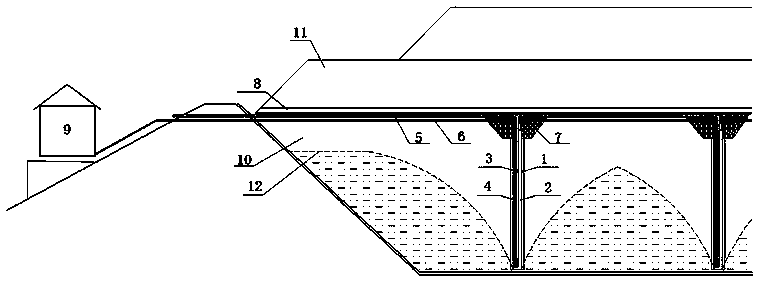

[0022] A method for aerodynamic reinforcement of a stack, comprising the following steps:

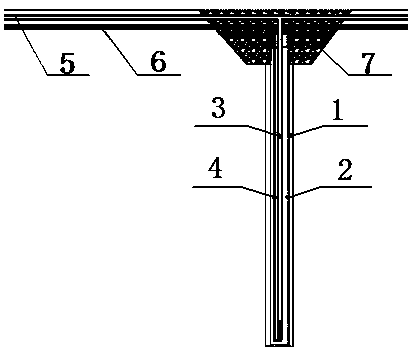

[0023] Step 1: Drill holes according to the specified number, angle and depth on the original pile body 10 containing interstitial water or gas to form a bottom-up drilling channel 1;

[0024] Step 2, put the seepage pipe 2 wrapped with a filter net into the passage in the above-mentioned drilled passage 1, so as to collect the infiltrated water;

[0025] Step 3, connect the outlet pipe 3 and the inlet pipe 4 with an elbow and bundle them together. Specifically, one end of the inlet pipe 4 can be changed in direction by 180 degrees with an elbow, and inserted into the outlet pipe 3, and the other end of the inlet pipe 4 is connected to the air intake system. 6;

[0026] Step 4, insert the outlet pipe 3 and the inlet pipe 4 into the seepage pipe 2, preferably at the bottom of the seepage pipe 2;

[0027] Step 5, connect the other ends of all outlet pipes 3 in series with plastic pipes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com