Detection device and method for measuring the surface shape of optical aspheric mirror by infrared interferometer

The technology of a detection method and a detection device, which is applied in the field of optical detection, can solve problems such as difficulty in measuring the surface shape of an aspheric mirror

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

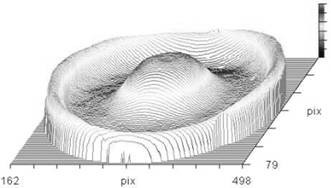

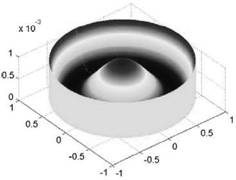

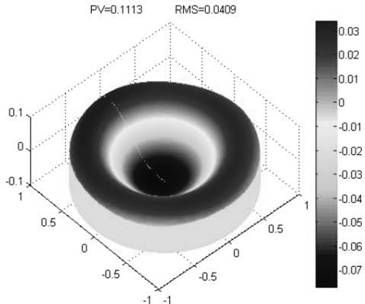

[0085] Embodiment 1: A detection device and method for measuring the surface shape of an optical aspheric mirror by an infrared interferometer, characterized in that the detection device includes an infrared laser interferometer, a spatial filter, a first collimating mirror, a reference mirror, and a beam splitter , standard lens, standard lens holder, lens holder to be tested, second collimating mirror, infrared detector, phase shifter, guide rail and computer, infrared laser interferometer, spatial filter, first collimating mirror, The beam splitter, standard lens holder and guide rail are arranged from left to right. The standard lens is placed on the standard lens holder, the lens holder to be tested is placed on the guide rail and slides along the guide rail, and the aspheric mirror to be tested is placed on the On the lens holder to be tested, the infrared laser interferometer, the spatial filter, the first collimator, the standard lens and the aspheric mirror to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com