Method for establishing one-tube multi-machine differential equation model through multi-machine form of tunnel and surge shaft

A differential equation model, surge well technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inconvenience in hydraulic transient applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

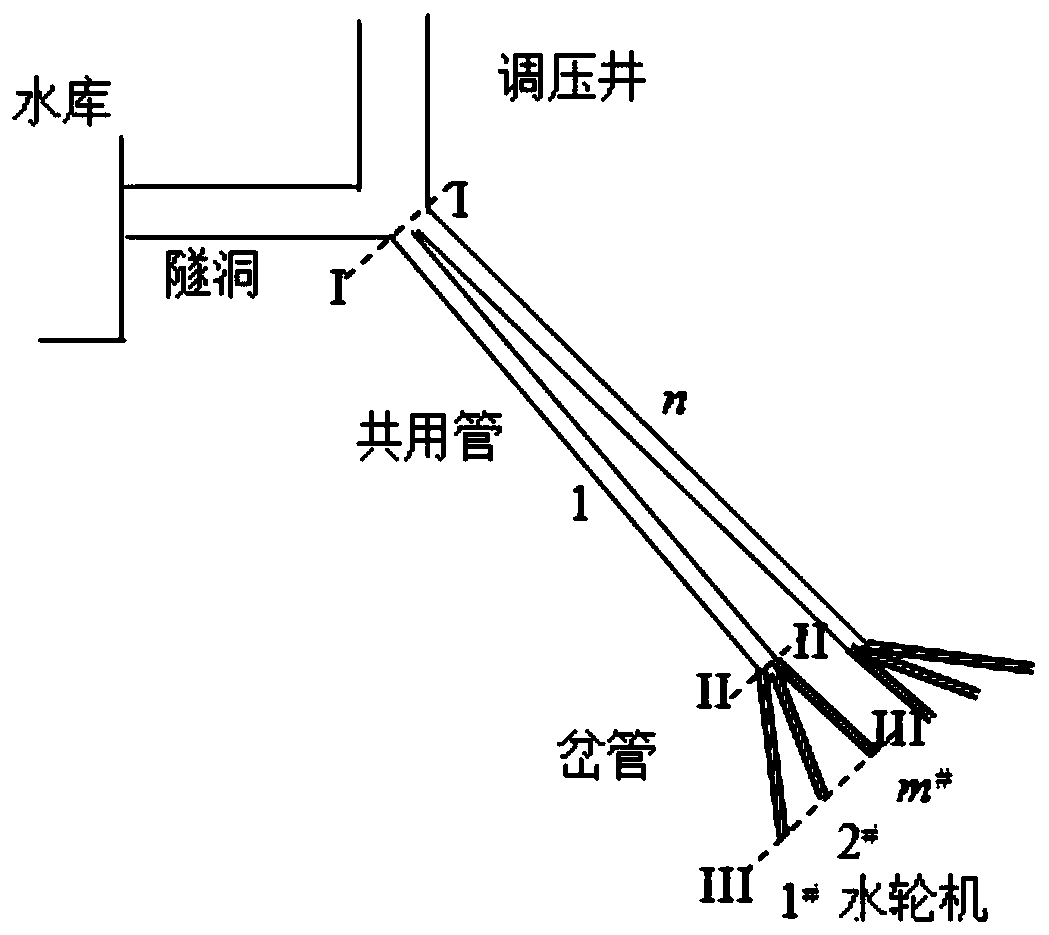

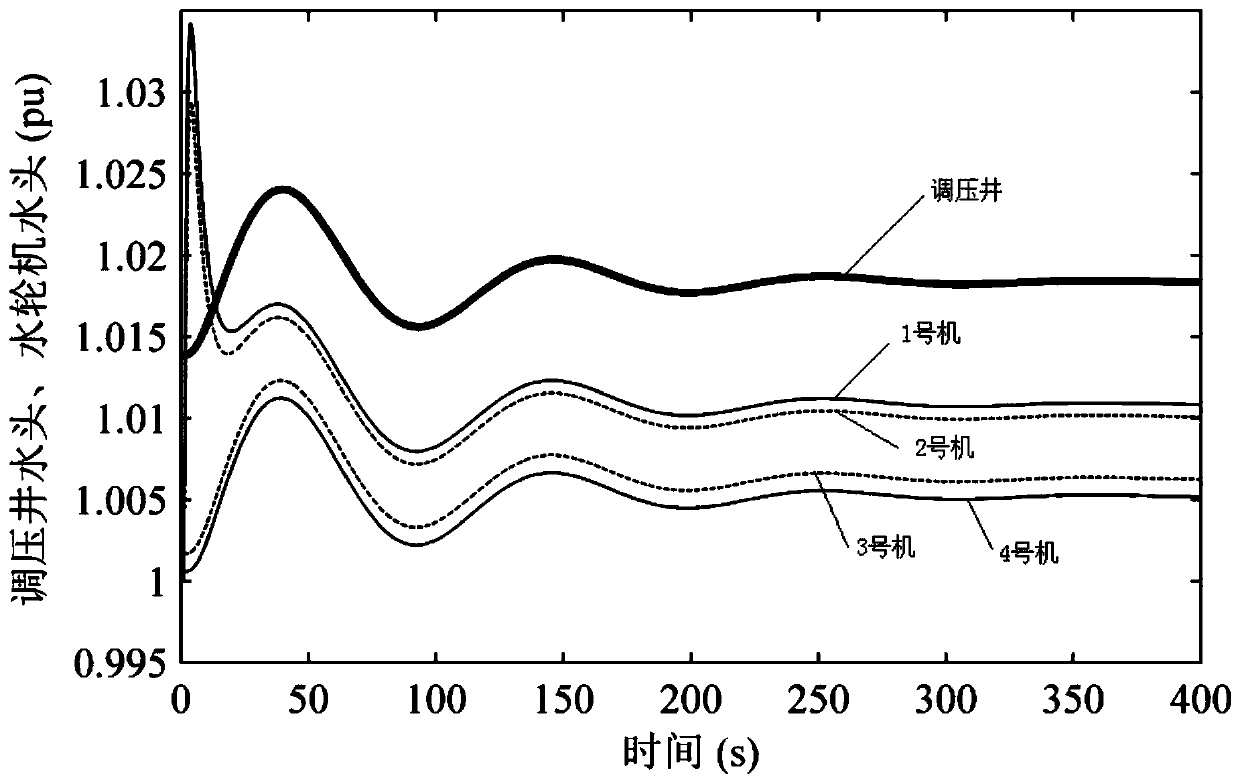

[0057] The layout and basic parameters of the hydraulic system of a power station are as follows: water is the water inlet and the surge shaft is a diversion tunnel with a diameter of 8 meters and a length of 932 meters; the height of the surge shaft is 65.8 meters and the inner diameter is 13 meters; The first penstock is 517 meters long and the second one is 490 meters long. The ends are divided into two bifurcated pipes with a diameter transitioning from 3.2 meters at the entrance to 2.2 meters to connect 4 turbines. In the simulation, No. 1 and No. 2 units share one common pipe, and No. 3 and No. 4 units share another common pipe.

[0058] Turbine parameters: H r =312m, Q r =53.5m 3 / s,P r = 150MW, n r =333.3rpm, tunnel flow inertia time constant T w =3.24376(s), surge well parameters: C s =774.06(s).

[0059] The turbine governor adopts a typical parallel PID structure, and the control parameters are: K p =5.0,K D =1.5,K I =2.5, bp=0.04, the execution cycle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com