An ultra-high voltage leaded capacitor and its preparation method

A capacitor and ultra-high voltage technology, which is applied in the field of capacitors, can solve the problems of immature manufacturing materials for capacitor components and the rated voltage of capacitors cannot reach 600V, and achieve safe and reliable production processes, increase electrical creepage distance, and improve high-voltage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

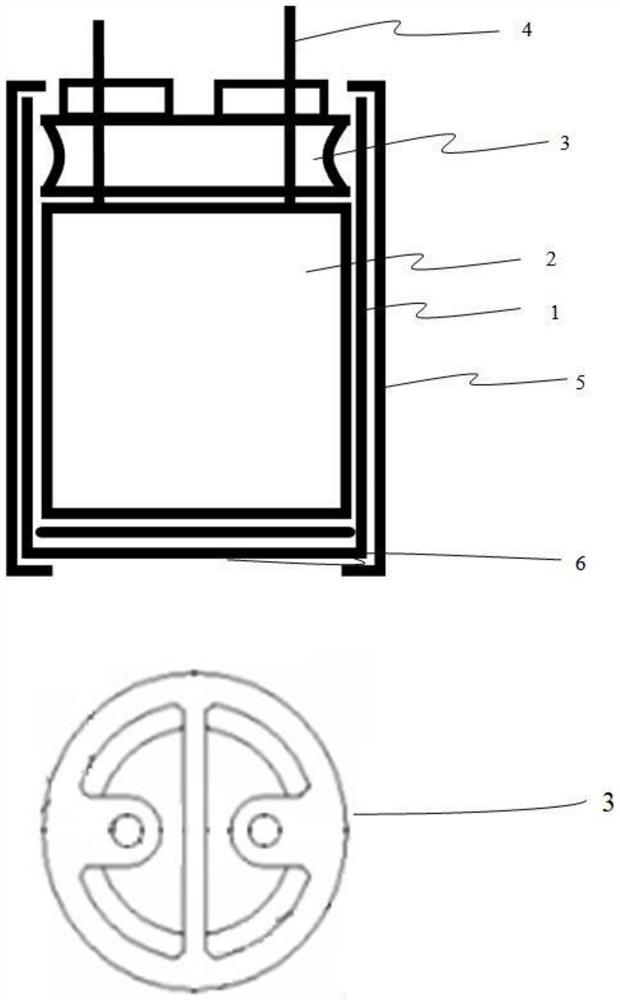

[0046] In this embodiment, please refer to figure 1 The present invention provides a lead-on ultra-high voltage capacitor and a preparation method for the existing lead ultra-high voltage capacitor without the rated voltage of 600 V, and provides a lead ultra-high voltage capacitor and a preparation method including an aluminum shell 1, a core package 2. , The bolus 3, the lead 4, the leading line 4 is fixed to the core packet 2, and the clip 3 is disposed at the end of the core 2 adjacent to the end 2, the lead line 4, The rubber plug 3 and the core packet 2 are arranged in the aluminum shell 1 from top to bottom.

[0047] The core package 2 includes an aluminum foil and an electrolytic paper, the core package (by the aluminum foil and the electrolytic paper lamination), the core package 2 is also impregnated with an electrolyte,

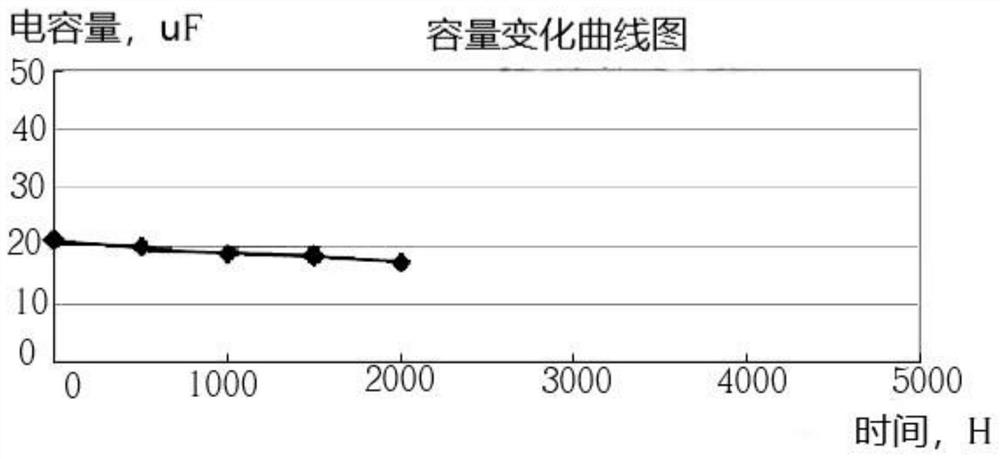

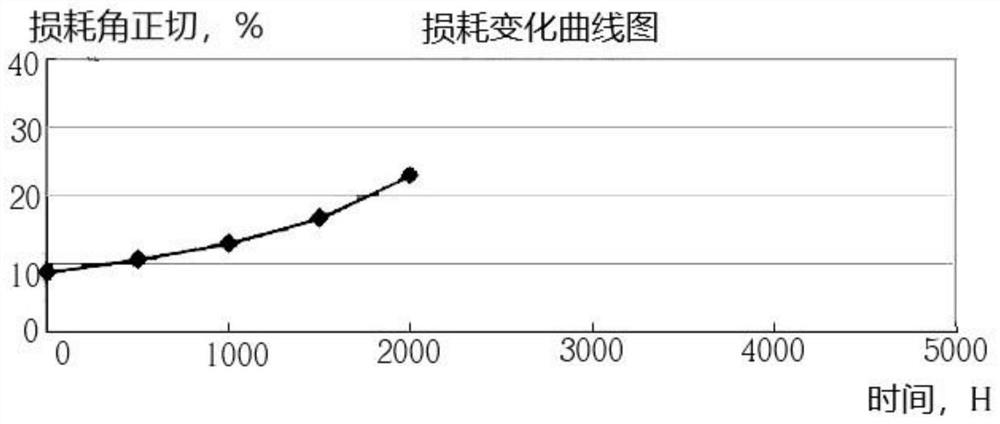

[0048] The electrolyte comprises a solute, a solvent, and an additive, the weight ratio of the solute is 15% to 25%, and the weight ratio of the solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com