Netting casting-type lead-acid battery positive electrode grid and fabrication method thereof

A lead-acid battery and anode plate technology, which is applied to battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of easy elongation and deformation of the anode grid, achieve high-rate discharge performance, increase service life, and improve specific energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the anode grid of the braided cast type lead-acid battery comprises the following steps:

[0026] (1) Twisting carbon fibers 3 with a diameter of 4 μm to prepare a carbon fiber bundle 2 with a diameter of 8 μm, and then arranging at least two carbon fiber bundles 2 to form a main carbon fiber bundle with a thickness of 8 μm, which is ready for use;

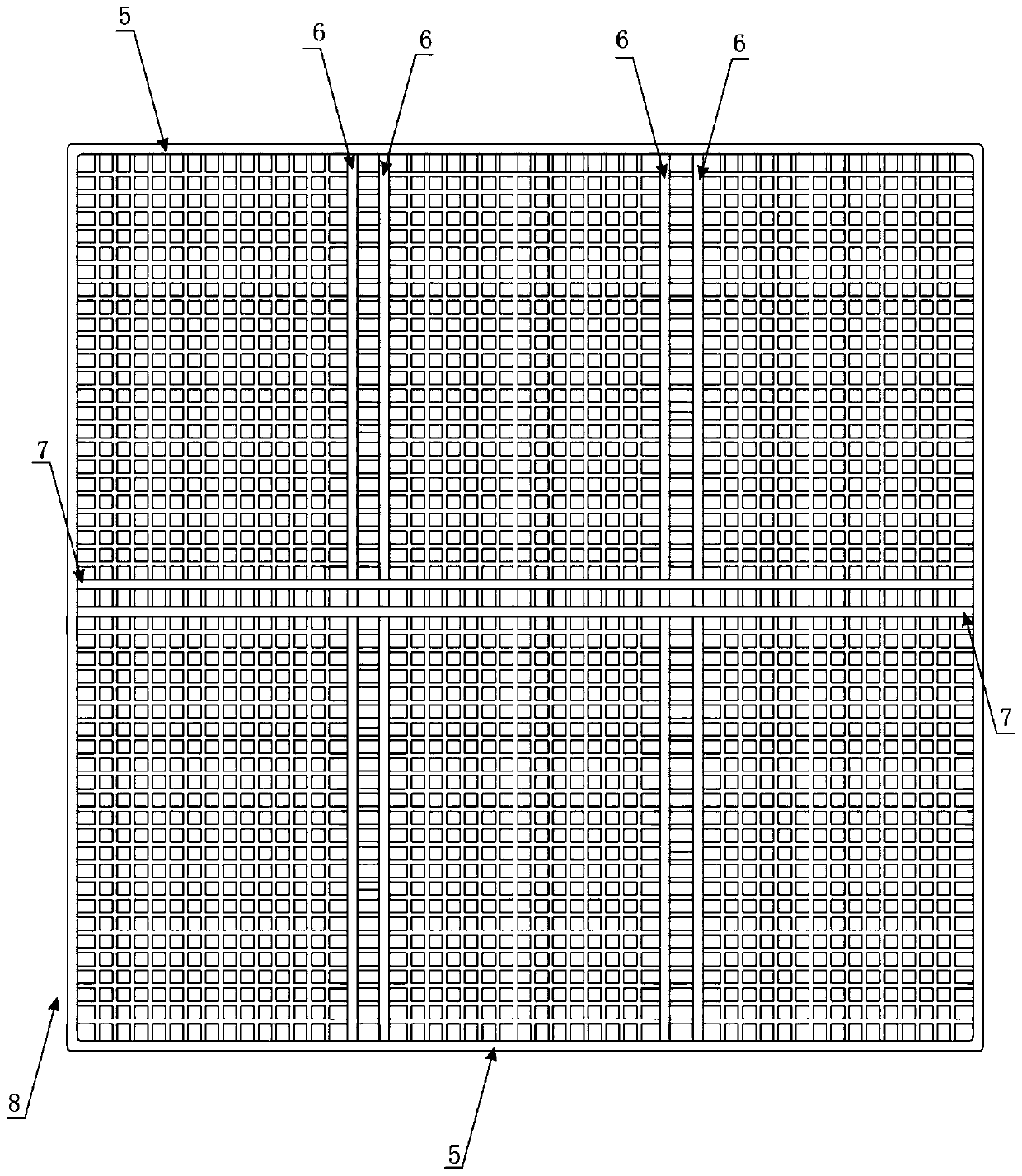

[0027] (2) Using the main carbon fiber bundle as the material, prepare a rectangular main frame body 5, then weave 14 carbon fiber bundles 2 at equal intervals along the longitudinal direction in the main frame body 5, and continue to weave two carbon fiber bundles 2 along the longitudinal direction. The longitudinal main carbon fiber bundle 6 of the gap forms the first longitudinal skeleton, and then continues to weave the nth longitudinal skeleton in the main frame body 5 according to the weaving method of the first longitudinal skeleton (in this embodiment, the value of n is 3, refer to figure ...

Embodiment 2

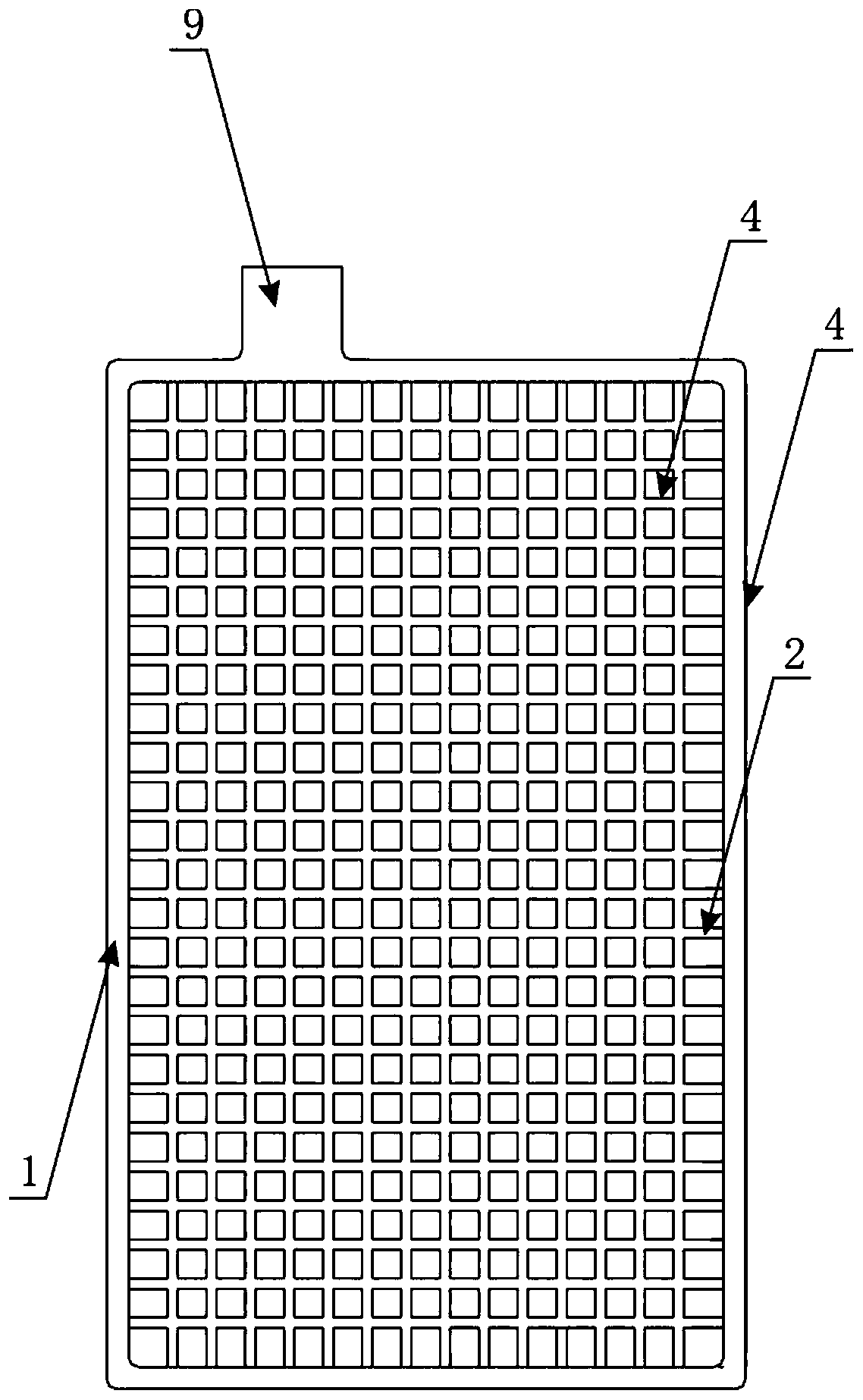

[0032] Such as figure 1 As shown, the anode grid prepared by the above method includes a rectangular frame 1 made of main carbon fiber bundles with a thickness of 3-50 μm.

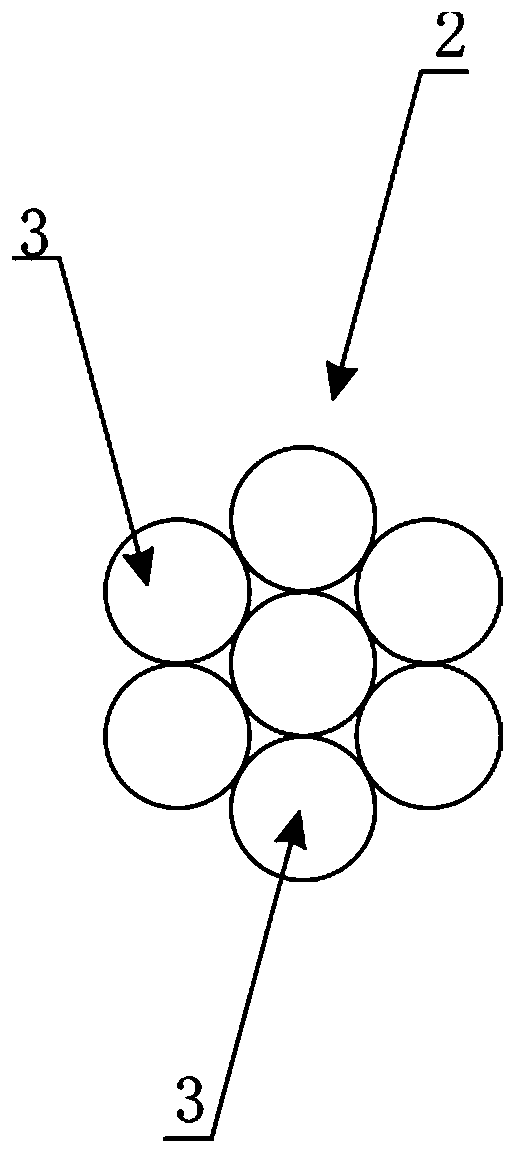

[0033] Such as image 3 with Figure 4 As shown, the main carbon fiber bundle is made of at least two parallel carbon fiber bundles 2 with a diameter of 3-50 μm, and the carbon fiber bundle 2 is formed by twisting several carbon fibers 3 .

[0034] Such as figure 1 As shown, in the frame body 1, 14 carbon fiber bundles 2 are fixed at equal intervals by welding along its longitudinal direction. The carbon fiber bundles 2 interlaced with each other make the inside of the frame body 1 in a grid shape.

[0035] Such as figure 1 As shown, tabs 9 made of lead-calcium alloy are fixed by welding at the end of the frame body 1 , and lead-calcium alloy layers 4 are coated on the frame body 1 and the carbon fiber bundles 2 .

Embodiment 3

[0037] 1. Under the conditions of normal temperature and pressure, the grid prepared in Example 1 and the grid made of pure lead material (pure lead grid) were subjected to a full charge and discharge test for two months. After the test, The extension length of the grid prepared by the present application is only 0.09-0.21 mm, while the extension length of the pure lead grid reaches 1.68-2.03 mm, which shows that the grid prepared by the method of the present invention has high strength and excellent deformation resistance.

[0038] 2. Under the conditions of normal temperature and pressure, the grid prepared in Example 1 and the surface of the grid (pure lead grid) made of pure lead material are coated with a paste layer, and then fully charged and discharged 150 times respectively Test, after the test, the paste applied on the surface of the grid prepared by the present application did not change, while the paste layer on the surface of the pure lead grid was "muddy" and coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap