Motor

A technology of electric motor and transmission mechanism, applied in the field of electric motor, can solve the problems such as the efficiency to be improved, the torque angle of the electric motor is not constant to zero, etc., to achieve the effect of no lateral edge effect, avoiding harmonics, and improving performance and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

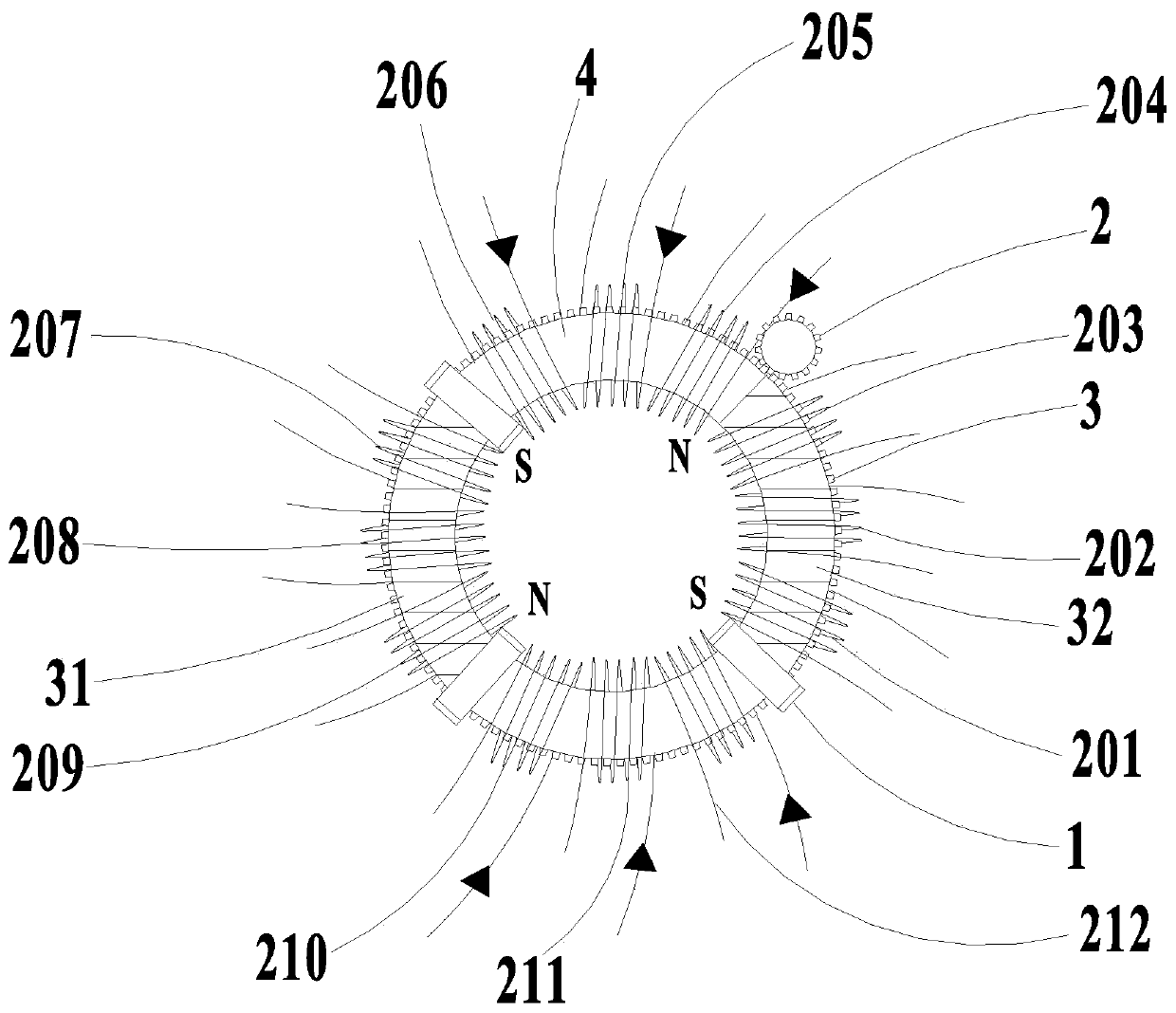

[0031] This embodiment relates to a motor, wherein an exemplary structure such as figure 1 shown. Depend on figure 1 It can be seen that the motor mainly includes two permanent magnets, two magnetically conductive parts 4 and stator coils, but is not limited thereto, multiple permanent magnets, magnetically conductive parts 4 and stator coils can be selected to maintain the stability of the motor when applied to the motor. stability, and can be better applied to different fields.

[0032] Wherein, the rotor is the moving part described in this embodiment, which mainly includes a permanent magnet 31, a permanent magnet 32 and two magnetically conductive parts 4 (equivalent to the stator core), specifically, the permanent magnet and the magnetically conductive part 4 are arranged at intervals and evenly distributed, and the combination is in the shape of a ring; the magnetic conduction part 4 is fixedly connected with the permanent magnet; Relatively; at the same time, the ...

Embodiment 2

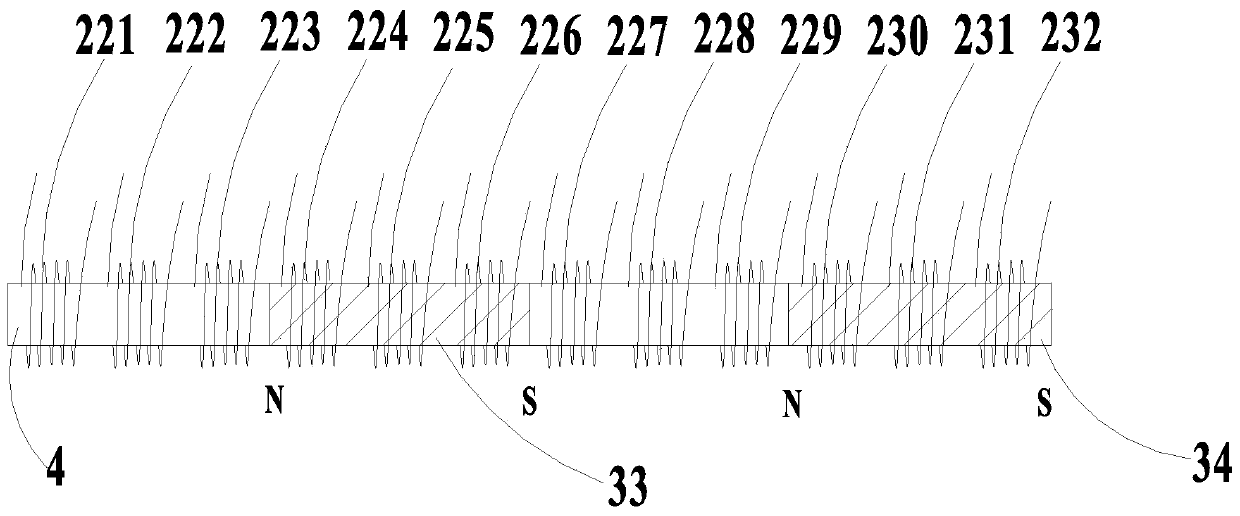

[0048] This embodiment relates to a motor, wherein an exemplary structure such as figure 2 shown. The structure of the motor of this embodiment is similar to that of Embodiment 1, the only difference is that the moving part of this embodiment is a mover, which is composed of two permanent magnets and two magnetic guide parts 4, and the two permanent magnets and two guides The combination of the magnetic parts 4 is linear.

[0049] The stator coils are tightly wound and sleeved on the outside of the mover, and the stator coils can be fixed inside the housing, and are divided into 12 groups. Wherein, the above-mentioned shell is made of magnetically permeable material. Specifically, such as figure 2 As shown, in the illustrated position, the twenty-first stator coil 221, the twenty-second stator coil 222, the twenty-third stator coil 223, the twenty-seventh stator coil 227, the twenty-eighth stator coil 228, the twenty-eighth stator coil 228, The twenty-ninth stator coil 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com