A kind of hec/cnc/polyisocyanate shape memory airgel and its preparation method and application

A polypolyisocyanate and polyisocyanate technology, which is applied in the field of HEC/CNC/polypolyisocyanate shape memory aerogel and its preparation, can solve the problems of poor mechanical properties, low recovery, and few recycle times of aerogels. , to achieve the effect of many cycles, high recovery performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

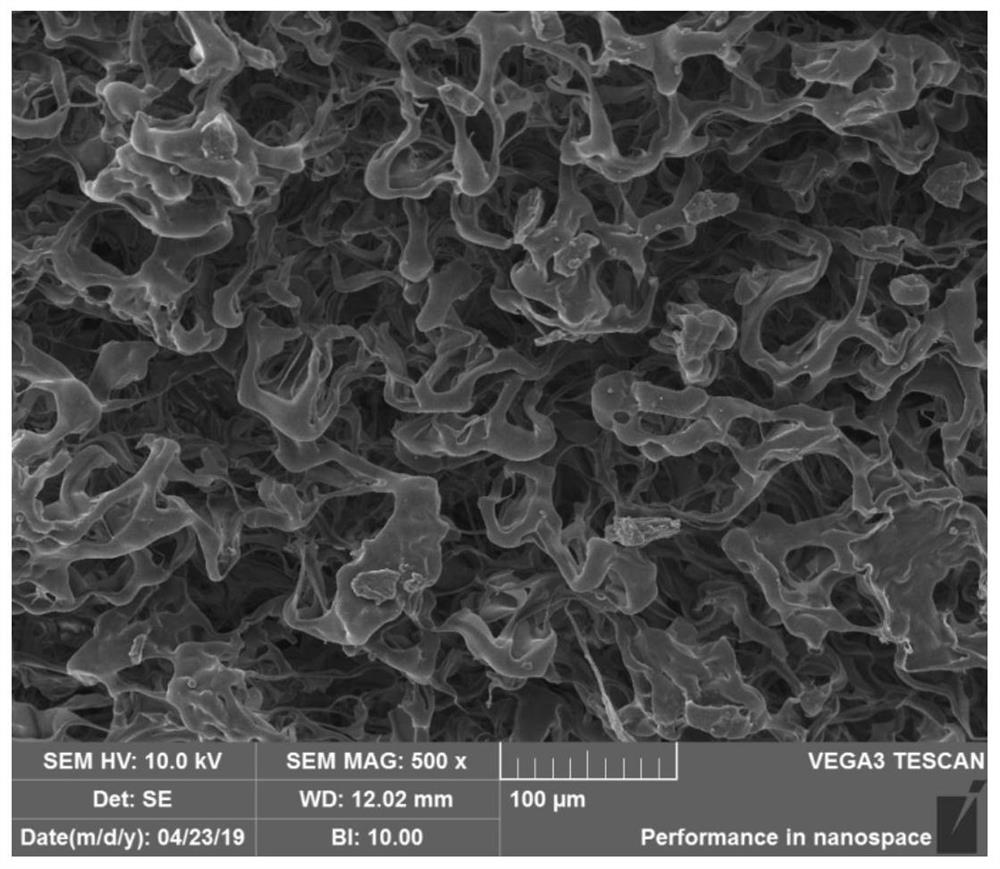

Image

Examples

preparation example Construction

[0024] The present invention provides a kind of preparation method of HEC / CNC / polyisocyanate shape memory airgel, comprising the following steps:

[0025] Step 1, mixing polyisocyanate and nanocellulose microcrystalline solution, stirring to obtain a uniform milky white mixed solution; wherein, polypolyisocyanate and nanocellulose microcrystalline solution are in a mass ratio of (1-3): 100 ratio Mixing; the polyisocyanate adopts water-soluble blocked polyisocyanate; the mass percent of the nanocellulose microcrystal solution is 1%-3%; the nanocellulose microcrystal solution is mixed with water and stirred until uniform Light blue solution, prepared.

[0026] Step 2, mix the mixed solution with the hydroxyethyl cellulose solution, stir, and ultrasonically degas to obtain the HEC / CNC / polyisocyanate solution; the mass ratio of the mixed solution to the hydroxyethyl cellulose solution is 1:(10-20 ) ratio mixing; the mass percentage of hydroxyethyl cellulose in the hydroxyethyl ce...

Embodiment 1

[0029] A kind of preparation method of HEC / CNC / polyisocyanate shape memory airgel of the present invention comprises the following steps:

[0030] Step 1. Mix hydroxyethyl cellulose with deionized water, let it stand for swelling for 1 hour, and stir to prepare a 1% hydroxyethyl cellulose solution by mass;

[0031] Step 2, mixing nanocellulose microcrystals with deionized water, stirring until a uniform light blue solution is obtained, and preparing a nanocellulose microcrystal solution with a mass percentage of 1%;

[0032] Step 3, mixing polyisocyanate with the nanocellulose microcrystalline solution in step 2 in a mass ratio of 1:100, stirring until uniform milky white is present, to obtain a mixed solution;

[0033] Step 4. Mix the mixed solution in step 3 with the hydroxyethyl cellulose solution in step 1 in a mass ratio of 1:10, stir, and ultrasonically degas for 0.5 h to obtain HEC / CNC / polyisocyanate solution;

[0034] Step 5. Place the HEC / CNC / polyisocyanate solution ...

Embodiment 2

[0038] A kind of preparation method of HEC / CNC / polyisocyanate shape memory airgel of the present invention comprises the following steps:

[0039] Step 1. Mix hydroxyethyl cellulose and deionized water, let it stand for swelling for 3 hours, and stir to prepare a hydroxyethyl cellulose solution with a mass percentage of 1.5%.

[0040] Step 2, mixing the nanocellulose microcrystals with deionized water, stirring to a uniform light blue solution, and preparing a nanocellulose microcrystal solution with a mass percentage of 1.5%;

[0041] Step 3, mixing polyisocyanate with the nanocellulose microcrystalline solution in step 2 in a mass ratio of 1.5:100, stirring until uniform milky white is present, to obtain a mixed solution;

[0042] Step 4. Mix the mixed solution in step 3 with the hydroxyethyl cellulose solution in step 1 in a mass ratio of 1:15, stir, and ultrasonically degas for 0.7h to obtain HEC / CNC / polyisocyanate solution;

[0043]Step 5. Place the HEC / CNC / polypolyisocy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com