Method for quickly constructing three-dimensional scene of underground fully mechanized coal mining face

A technology of fully mechanized mining face and three-dimensional scene is applied in the field of rapid construction of three-dimensional scene of underground fully mechanized mining face, which can solve the problems of inability to accurately judge the operation status of fully mechanized mining equipment, difficult to obtain clear images from video monitoring, and huge maintenance workload. , to achieve the effect of rapid construction, reducing casualties, and solving perception problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

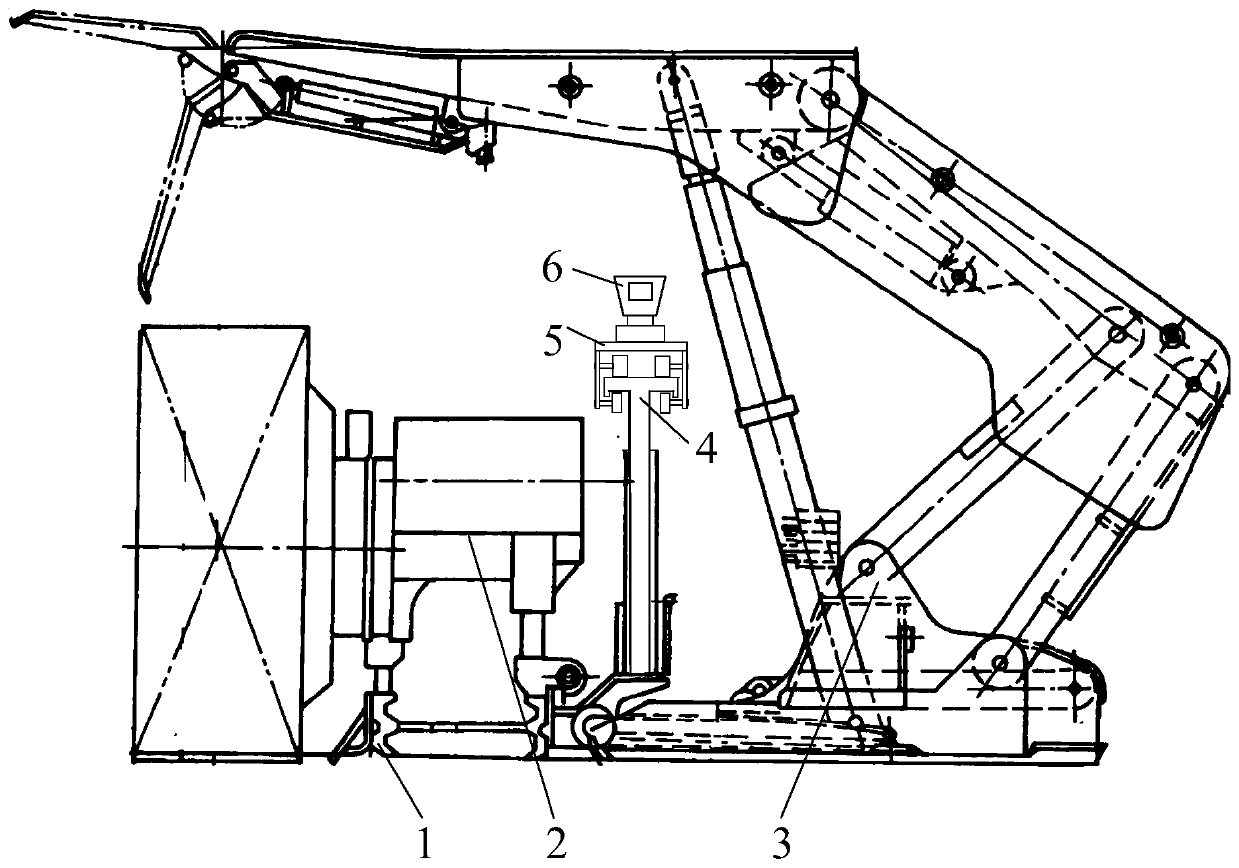

[0047] like figure 1 Shown, be the schematic diagram that laser radar imaging system 6 of the present invention is installed on fully mechanized mining face, laser radar, IMU and odometer are installed on the mobile platform 5, mobile platform 5 moves fast on flexible track 4, and flexible track 4 Installed on the track support frame outside the side of the scraper conveyor 2; the mobile platform 5 includes a moving mechanism, a platform seat, a drive motor with an encoder, a position sensor, a control module, a communication module and a power supply module; the flexible track 4 As the scraper conveyor moves, it can be self-adaptive and self-adjusting to ensure the rapid passage of the mobile platform.

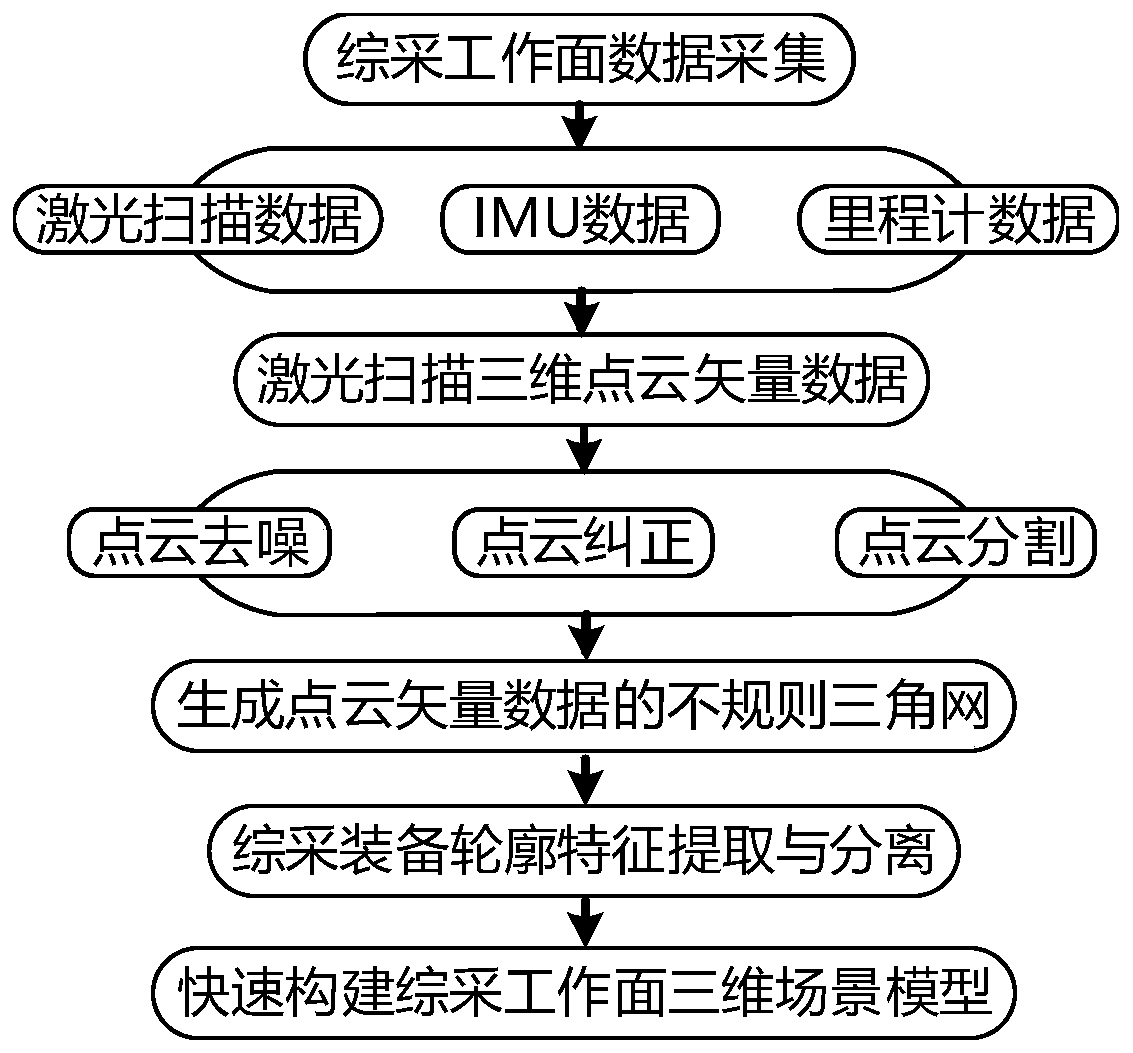

[0048] like figure 2 As shown, the method for quickly constructing a three-dimensional scene of an underground fully mechanized mining face of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com