Thermoplastic polyurethane film and preparation method therefor

一种聚氨酯膜、热塑性的技术,应用在热塑性聚氨酯膜及其制备领域,能够解决难以制备厚的聚氨酯膜、不容易控制热塑性聚氨酯膜物理特性等问题,达到耐久性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Preparation of polyurethane resin composition

[0074] Prepare polycarbonate diol (PCDL, Asahi Kasei Chemicals Corporation) having a number average molecular weight of 2,050 g / mol as a polyol, 1,4-butanediol (1,4BD, manufactured by BASF Industries) as a chain extender, As the first isocyanate-based curing agent, H12MDI containing 2 isocyanate functional groups (manufactured by Evonik Industries), as the second isocyanate-based curing agent, isophorone diisocyanate (IPDI, manufactured by Evonik Industries), as a catalyst Dibutyltin laurate (DBTDL) and methyl ethyl ketone as organic solvent. Thereafter, a mixture wherein the content of the polyol is about 70.03% by weight, the content of the chain extender is about 6.64% by weight, and the content of the second isocyanate-based curing agent is about 23.33% by weight is prepared, and by adding 100 parts by weight of the mixture Mixed with about 50 parts by weight of an organic solvent to prepare a mixed solution.

[0075...

Embodiment 2 to 4

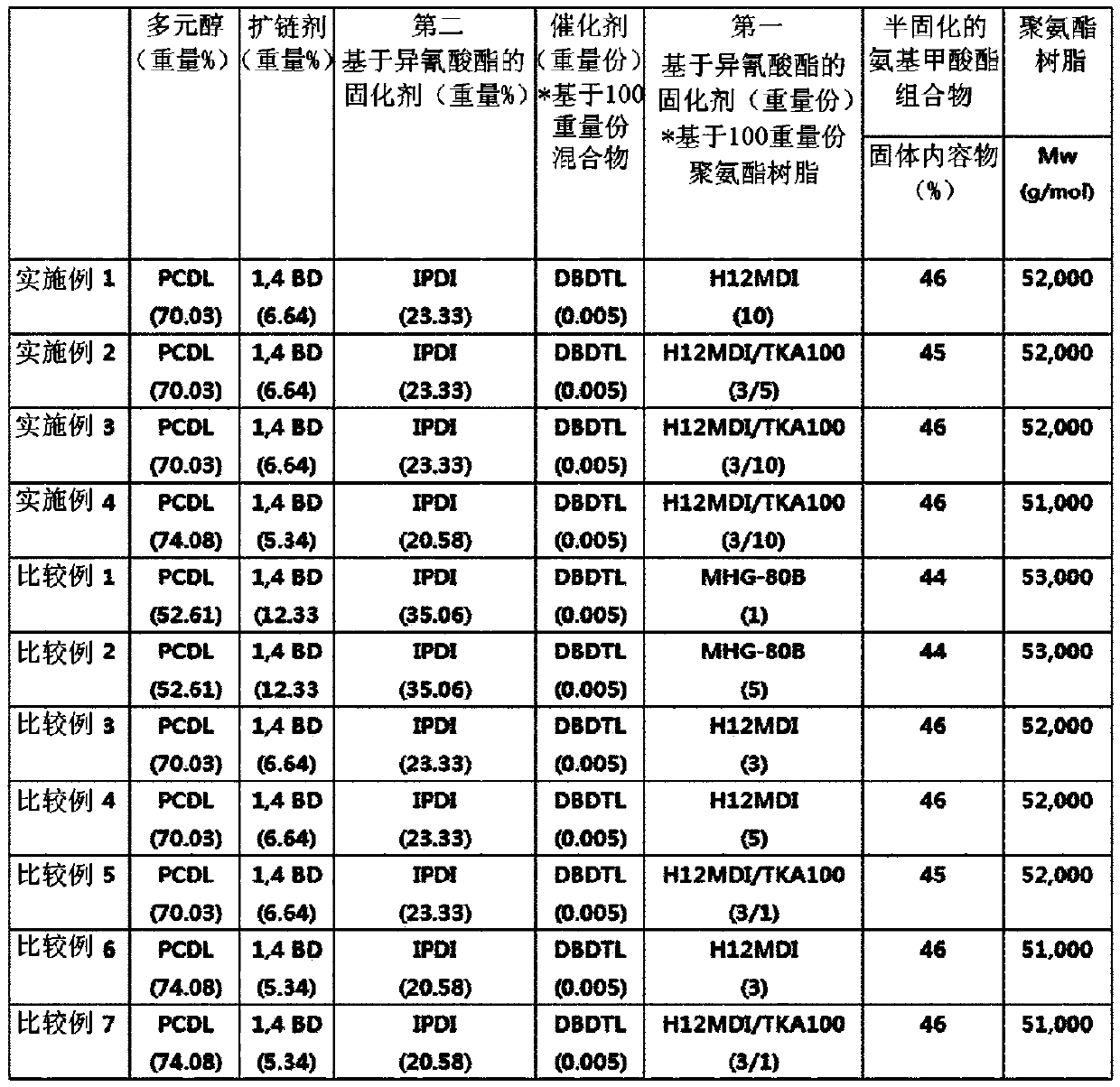

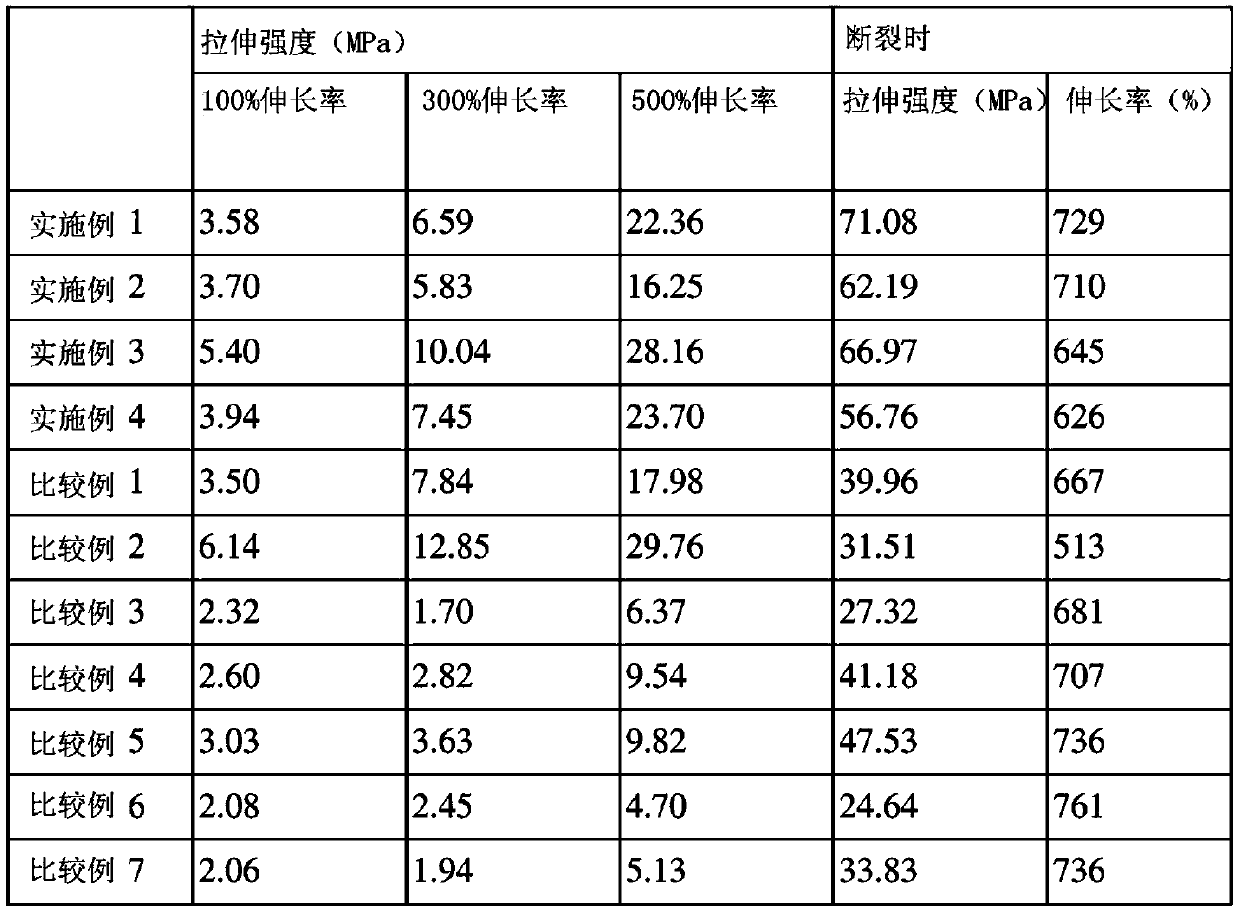

[0079] A thermoplastic polyurethane film was prepared in the same manner as in Example 1, except that, in order to prepare the polyurethane resin composition, a polyol, a chain extender, a first isocyanate-based curing agent, a second based Curing agent and catalyst for isocyanates. In Table 1 below, TKA-100 is a trifunctional isocyanate-based curing agent manufactured by Asahi Kasei Chemicals Corporation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com