Thermal insulation composite plate and applications thereof

A technology for thermal insulation and composite panels, applied in the field of composite panels, can solve the problems of panel blistering or concave deformation of composite panels, low temperature resistance of panel thickness, waste of reworked materials, etc., to improve affinity and bonding strength, The effect of solving the debonding protrusion deformation and improving the bonding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

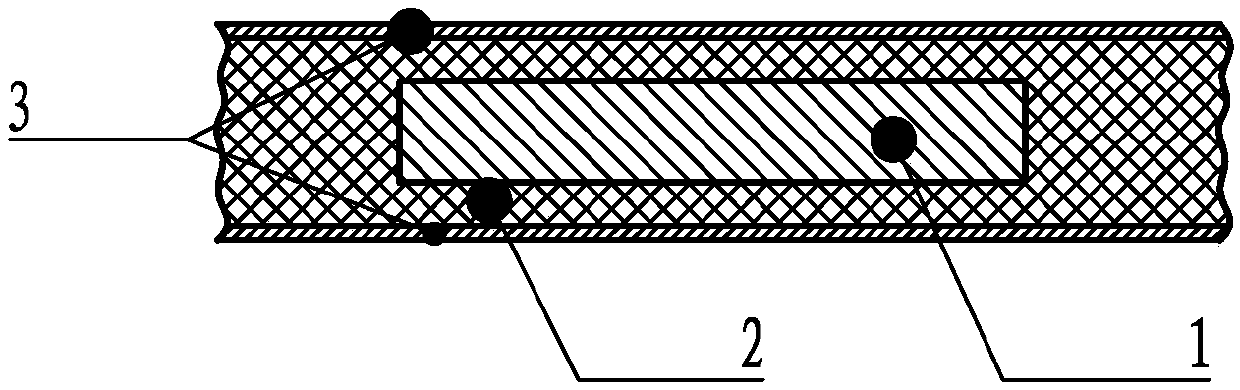

[0034] refer to Figure 4 , a thermal insulation composite panel, comprising: a vacuum insulation panel 1, a PU hard foam filling layer 2 and a panel 3; The upper and lower surfaces of the foam filling layer; so that the PU hard foam filling layer 2 is arranged between the panel 3 and the vacuum insulation panel 1;

[0035] The PU hard foam filling layer 2 and the panel 3 are bonded through the fiber layer 4 .

[0036] By coating a layer of fiber layer 4 on the surface of panel 3, the surface state of panel 3 is improved, and its affinity and bonding strength with PU hard foam filling layer 2 are improved, thereby greatly improving the adhesion between the two. Junction reliability, to avoid problems such as debonding due to low bond strength.

[0037] Since the fiber layer 4 is added to the thermal insulation composite board, it not only greatly improves the bonding strength between the PU hard foam filling layer 2 and the panel 3, but also can connect the PU hard foam fill...

Embodiment 2

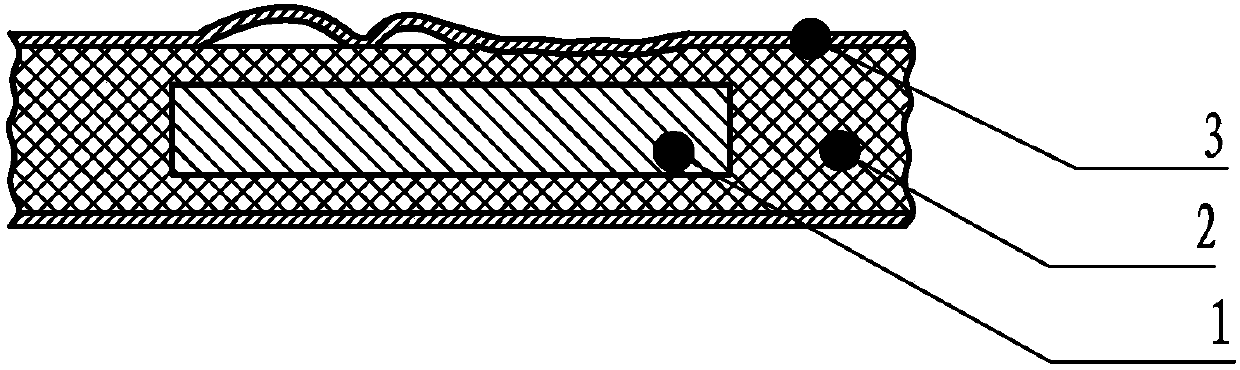

[0042] refer to Figure 5 , The difference between this embodiment and Embodiment 1 is that: the vacuum insulation panel 1 and the PU hard foam filling layer 2 are bonded by the fiber layer 4 .

[0043] By coating a layer of fiber layer 4 on the vacuum insulation panel 1, the bonding strength between the vacuum insulation panel 1 and the PU hard foam filling layer 2 is improved, thereby solving the problem of the adhesion between the PU hard foam filling layer 2 and the vacuum insulation panel 1. The problem of convex deformation occurs in the prison.

[0044] Since the fiber layer is added to the thermal insulation composite panel, it not only greatly improves the bonding strength, but also slowly permeates and discharges the gas brought in during the folding process of the vacuum insulation panel 1 through the fiber layer 4, thus avoiding the heat preservation The thermal insulation composite board has quality problems such as blistering and bumping.

[0045] Destruction e...

Embodiment 3

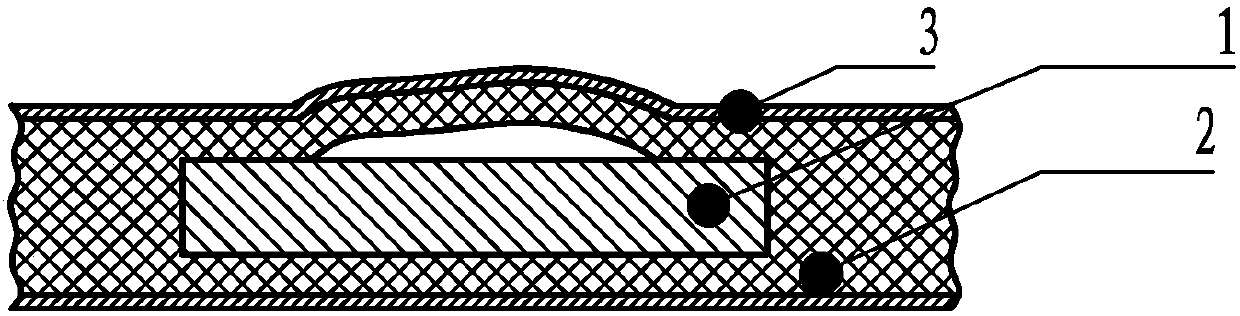

[0047] refer to Figure 6 , The difference between this embodiment and Embodiment 1 is that: the vacuum insulation panel 1 and the PU hard foam filling layer 2, and the PU hard foam filling layer 2 and the panel 3 are respectively bonded by the fiber layer 4. In this way, the advantages between Embodiments 1 and 2 are simultaneously possessed.

[0048]The thermal insulation composite board mentioned above can be applied to thermal insulation and energy-saving products, wherein the thermal insulation and energy-saving products refer to products that can reduce temperature and energy loss through barrier technology. Specifically, it is an insulated box or an insulated wall panel or a refrigerator or a refrigerated container or an electric water heater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com