Silent self-cleaning type completely-automatic solid-liquid separation apparatus

A solid-liquid separation, fully automatic technology, applied in the field of water treatment, can solve the problems of loud noise, low filtering effect, occupation, etc., and achieve good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

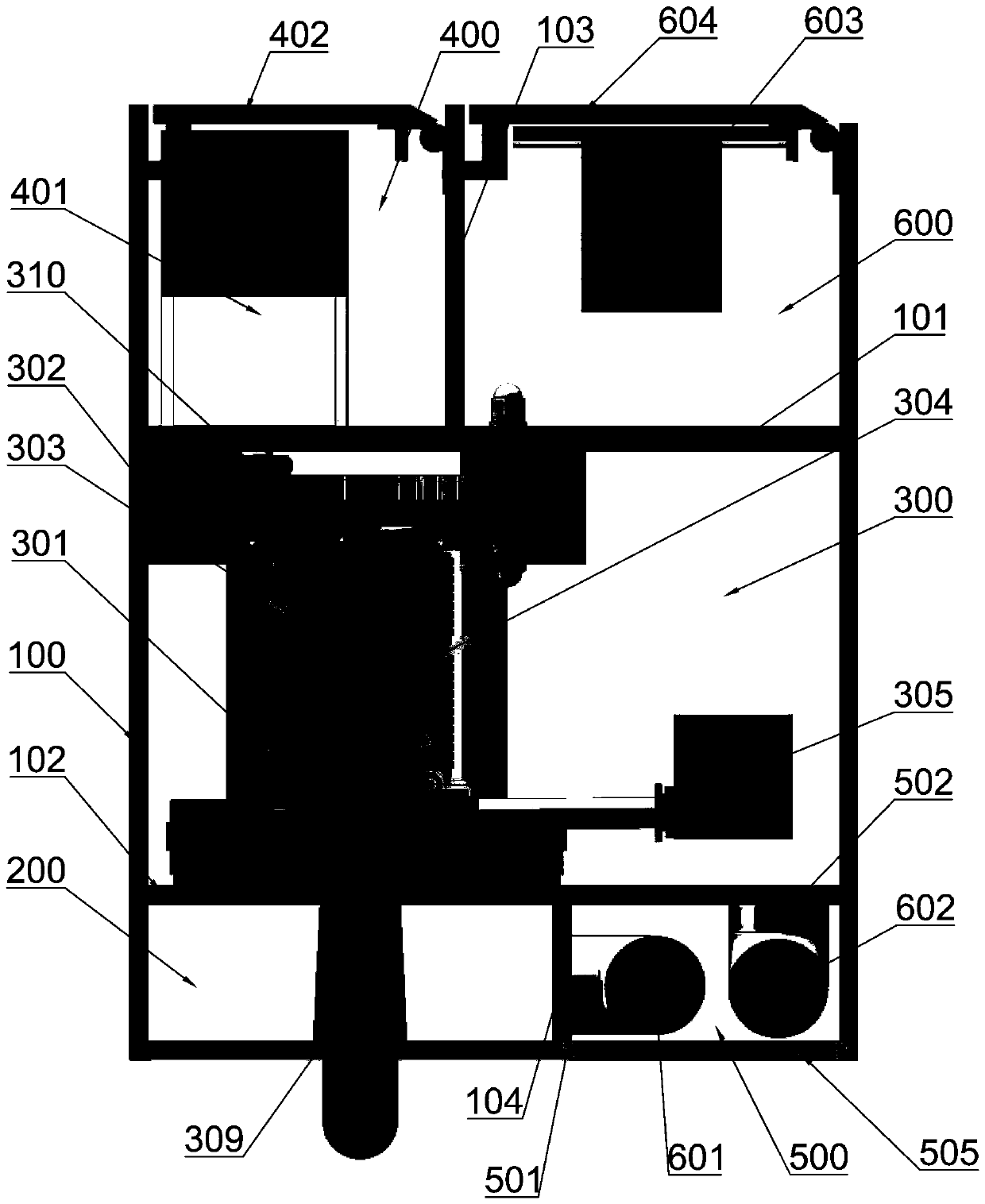

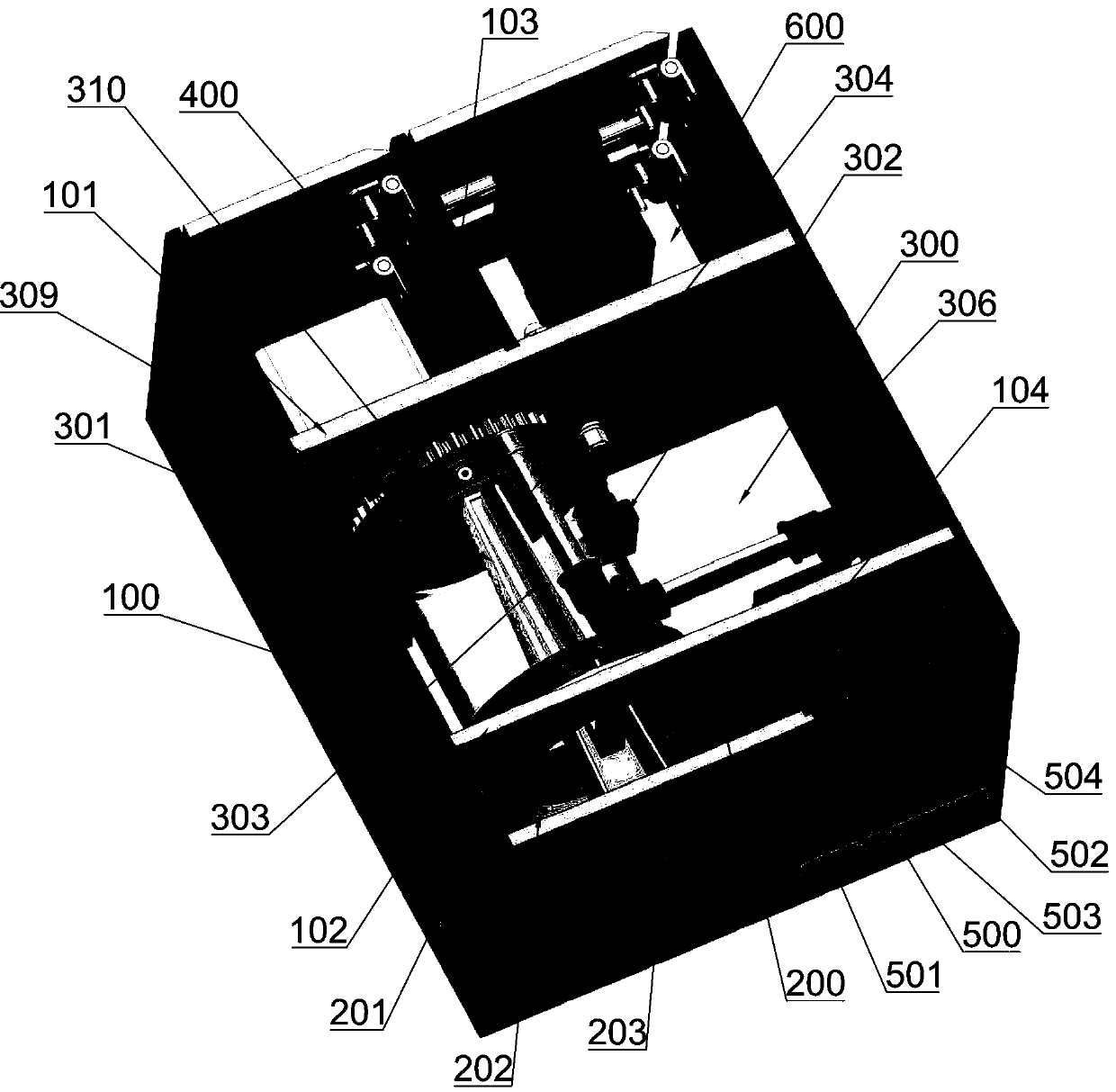

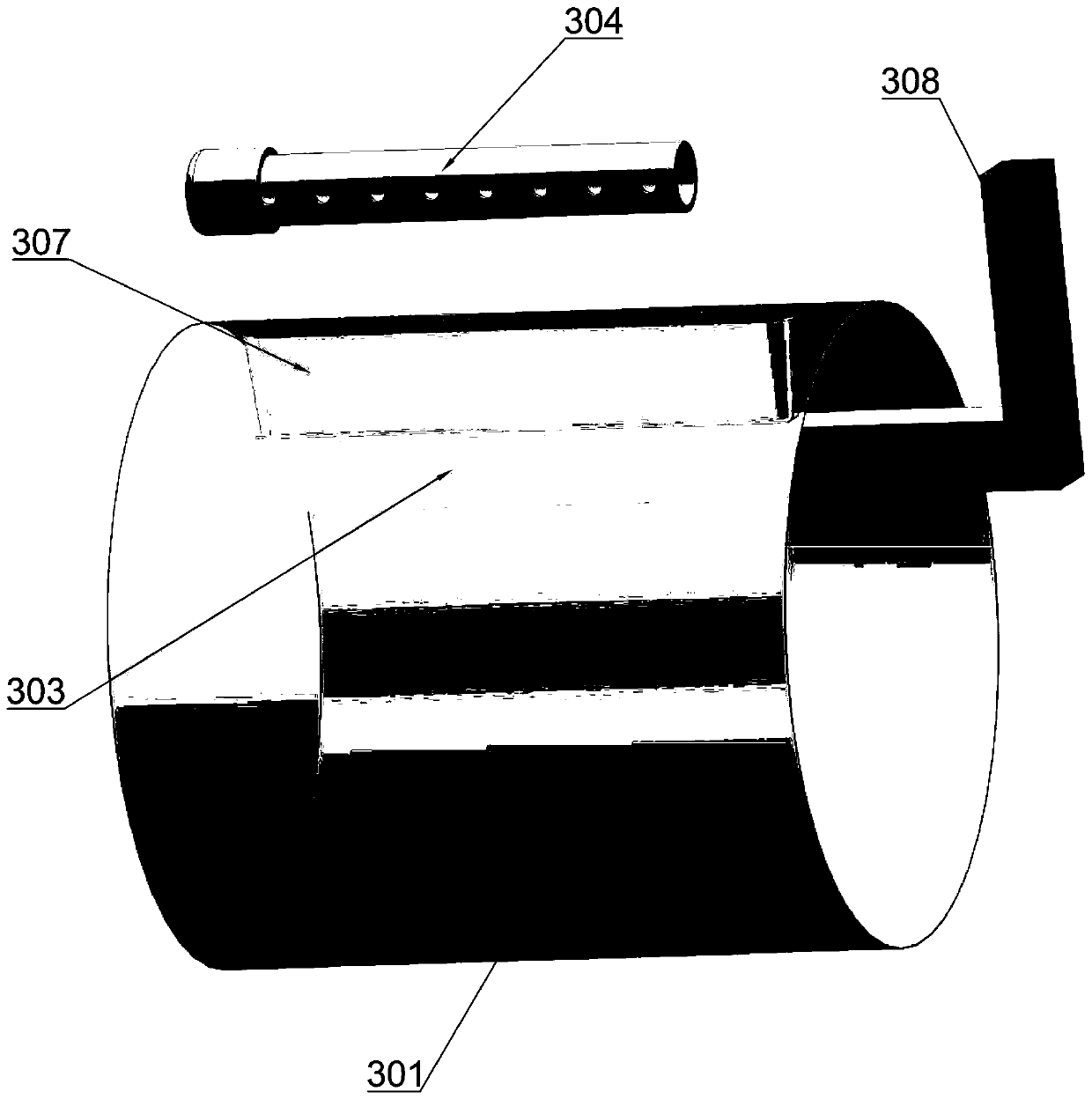

[0046] refer to Figure 1-Figure 3As shown, a silent self-cleaning fully automatic solid-liquid separation device, which includes a housing 100, a water inlet unit 200 arranged in the housing, a filtration and self-purification functional unit 300 connected to the water inlet unit, and a filter and self-purification functional unit. The motor unit 400, the water level observation unit 500 connected with the water inlet unit and the filtering and self-purification functional unit, and an independent control unit 600. All units are arranged in the housing 100 .

[0047] The shell 100 is provided with a first partition 101 and a second partition 102 in parallel, the first partition 101 is at the top, and the second partition 102 is at the bottom; the first partition 101 and the second partition 102 divide the internal space of the shel...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap