Unpowered dumping tray type automatic sorting machine

An automatic sorting machine and power technology, which is applied in the field of logistics cargo sorting, can solve the problems of large floor space, high ground flatness requirements, and high maintenance costs, and achieves small floor space, good versatility, and economy. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

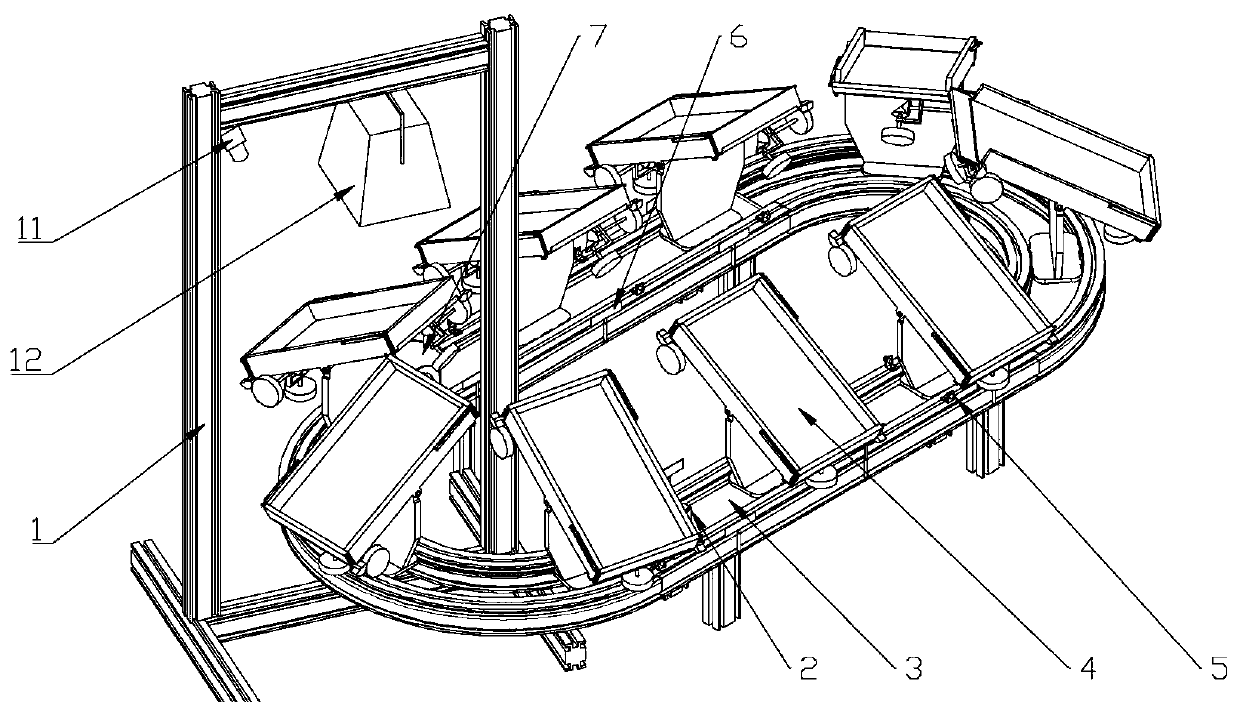

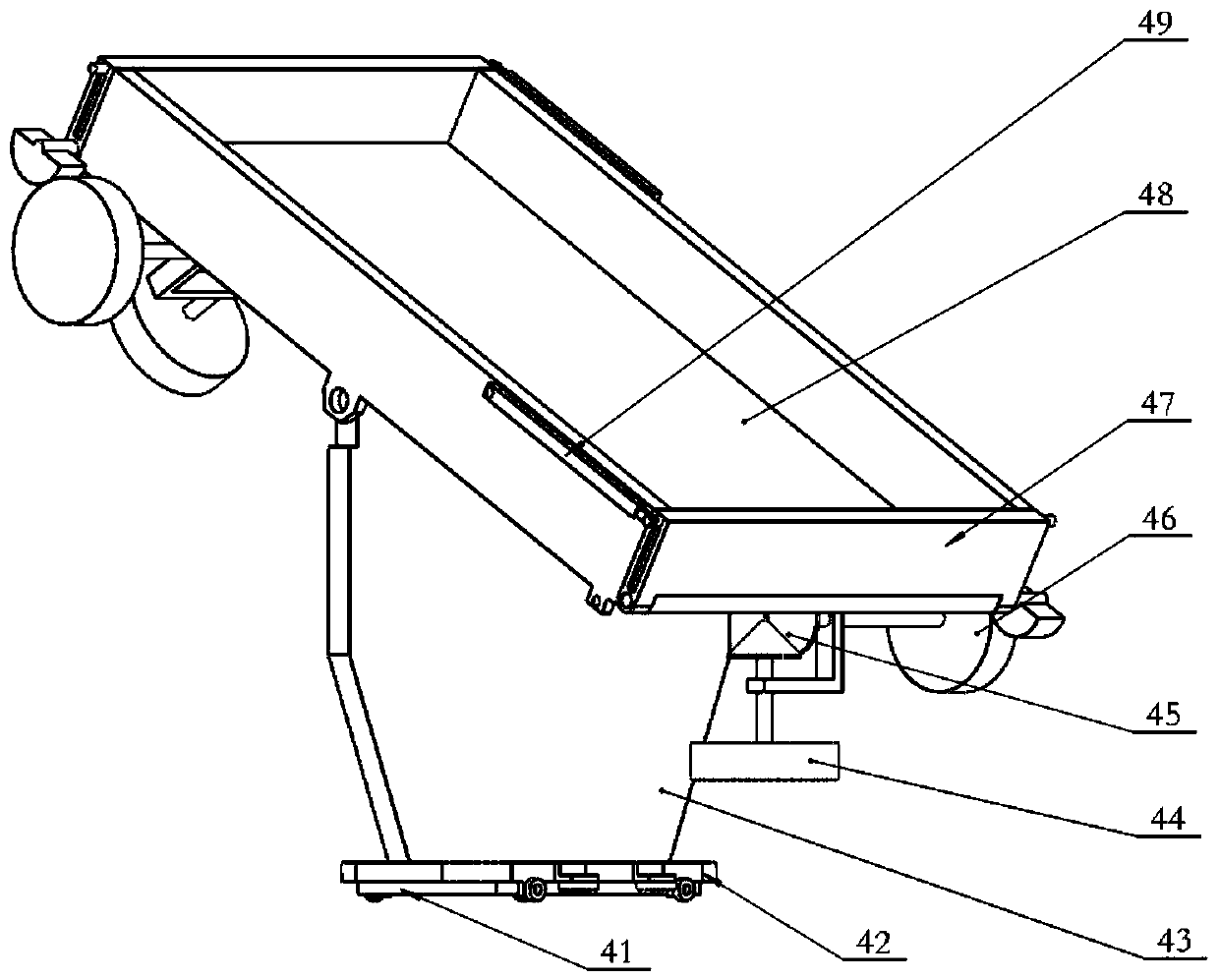

[0034] see image 3 , the unpowered sorting trolley 4 moves through the friction between the bottom soft rubber 41 and the belt conveyor 3, the soft rubber 41 is bonded to the trolley base 42, the sorting compartment 48 can be overturned on both sides under the support of the support plate 43, and the transmission The mechanism is driven by the friction wheel 44, driven by the bevel gear 45, and transmitted to the cylindrical gear 46 for transmission so as to open the compartment door 47, and the compartment door 47 is restored to its original position by the return spring 49;

[0035] The sorting trolleys 4 are connected end to end to ensure that the distance between the sorting trolleys 4 remains unchanged. The photoelectric sensor 5 is used to accurately determine the real-time position of the sorting trolley 4. When the sorting condition is reached, the photoelectric sensor 5 is used as a switch signal. The push-out mechanism 6 moves, and after the cylinder is pushed out, ...

Embodiment 2

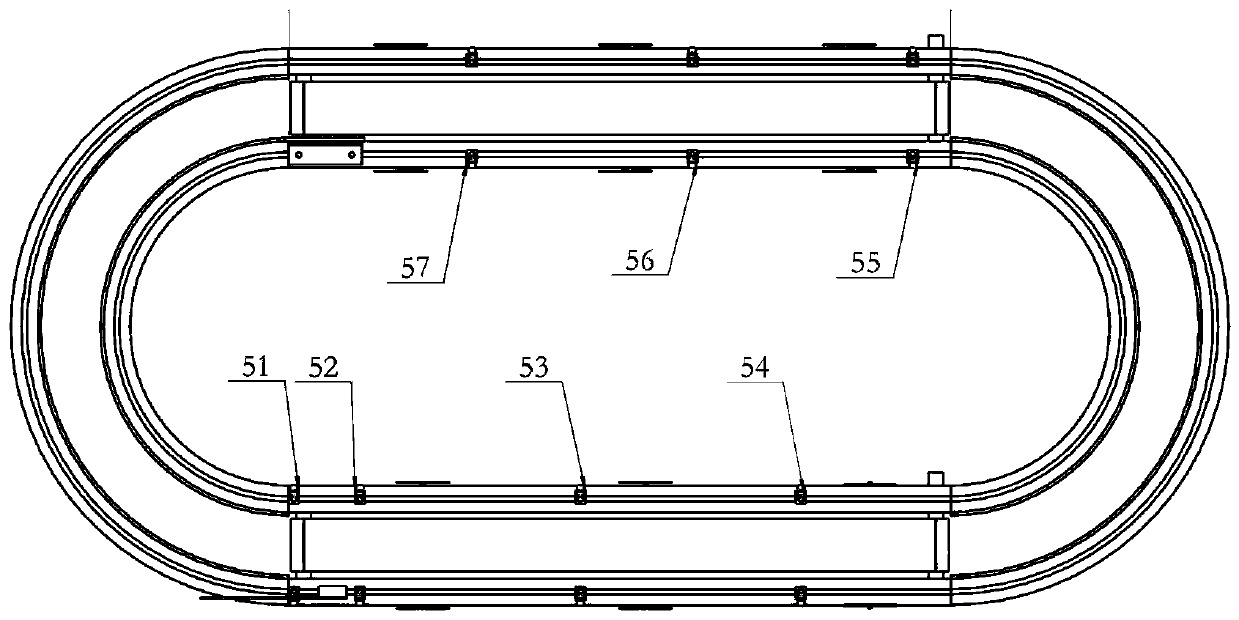

[0037] see figure 2 and Figure 4 , the sorting port discrimination device uses a photoelectric sensor 5, set the photoelectric sensor 5 as a trigger in the turning section, one group is used as an industrial camera action trigger, and one group is used as a configuration program refresh trigger. After two groups of triggers, the system processes the key information of the express delivery And make a judgment, through the photoelectric sensor 51, if it is the outer sorting port of the group ring, the distributing mechanism 2 will not act, if it is the inner sorting port, the biaxial cylinder 21 of the distributing mechanism 2 will act, and keep, the sorting trolley The bottom of the sorting compartment 48 of 4 is in contact with the buffer rail 22 and turned over to complete the direction separation action;

[0038] The photoelectric sensor 5 and the push-out mechanism 6 are co-installed. One group of photoelectric sensors 5 controls two groups of push-out mechanisms 6. The ...

Embodiment 3

[0041] see figure 1 , the front-end scanning device 1 includes an industrial camera 11, an external light source 12 and a capacitive touch all-in-one machine. The industrial camera 11 and the external light source 12 are installed on a square mounting frame and located above the belt conveyor 3. The capacitive touch all-in-one machine adopts an external landing Type bracket installation, and as the carrier of the information processing system;

[0042] After the courier is packaged, it is triggered by a group of photoelectric sensors 5, and the industrial camera 11 takes a picture, and processes it through the halcon software to extract the key sorting information, store it in the TXT text, and the sorting trolley 4 carrying the courier passes by. The next group of photoelectric sensors 5 is triggered, the configuration program is run once, the information in the TXT text is extracted, and the information is processed as a judgment condition, and the distribution information a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com