Processing method for sensor copper shell

A processing method and sensor technology, which is applied in the field of sensor shells, can solve the problems of easy corrosion of the outer surface of the copper shell and loose installation of probes on the copper shell of the sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

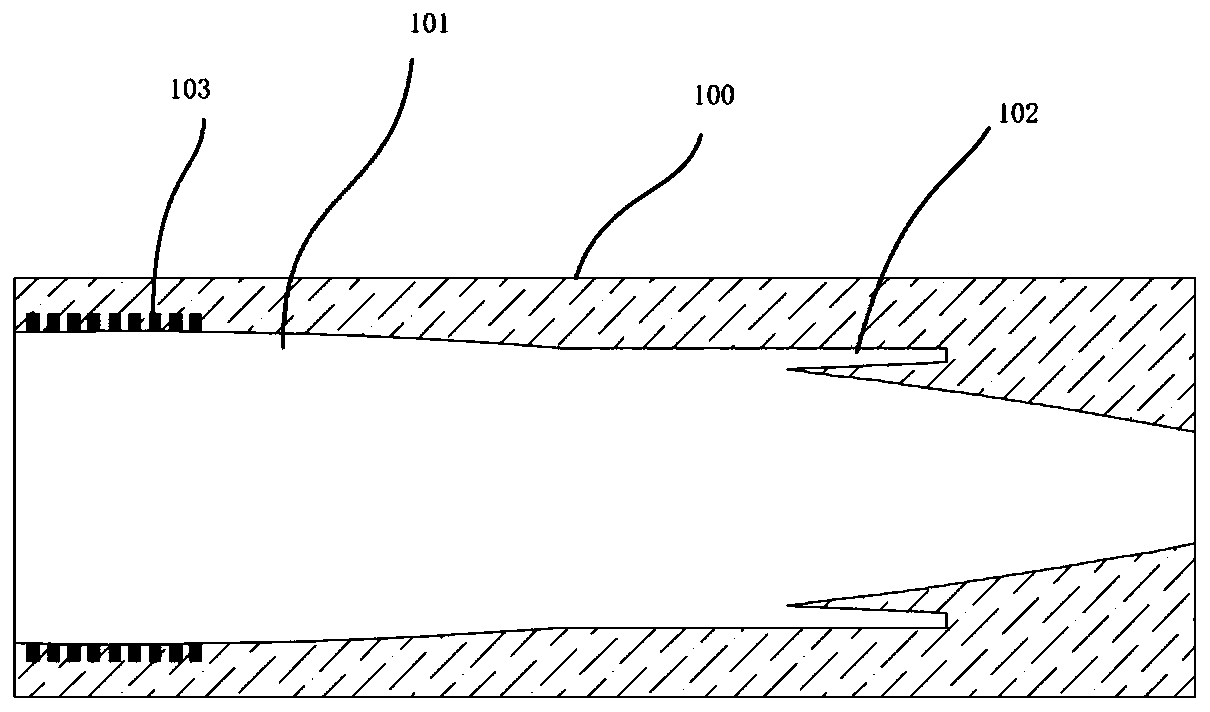

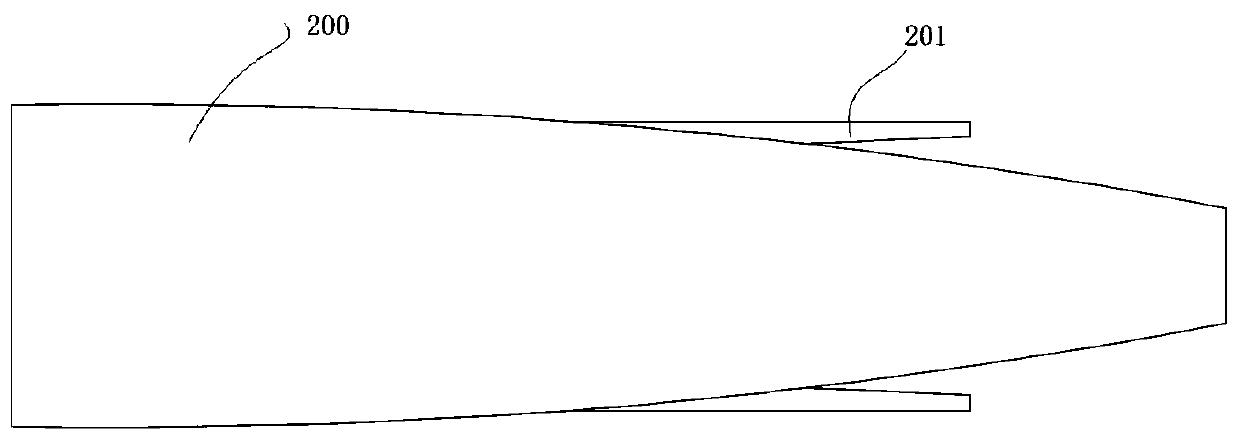

[0029] A method for processing a sensor copper shell, comprising the steps of:

[0030] S1: blank shell preparation, the inner mold is placed in the cylindrical outer mold, liquid copper water is injected between the inner mold and the outer mold, and after the copper water is cooled, the inner mold and the outer mold are smashed to obtain the blank shell ; Through this step, the blank shell is obtained, and this step is prepared by a traditional method;

[0031] S2: rough shell preparation, on the inner wall of one end of the blank shell with a larger opening, the inner mounting thread is turned by a lathe to obtain the rough shell; the depth and spacing of the installed internal thread are adjusted according to actual needs;

[0032] S3: Preparing the fine shell, washing the inside and outside of the rough shell prepared in step S2 with high-pressure water for 10-15 seconds, and then drying it with high-temperature nitrogen at 300°C; washing with high-pressure water is to re...

Embodiment 2

[0039] A method for processing a sensor copper shell, comprising the steps of:

[0040] S1: blank shell preparation, the inner mold is placed in the cylindrical outer mold, liquid copper water is injected between the inner mold and the outer mold, and after the copper water is cooled, the inner mold and the outer mold are smashed to obtain the blank shell ; Through this step, the blank shell is obtained, and this step is prepared by a traditional method;

[0041] S2: rough shell preparation, on the inner wall of one end of the blank shell with a larger opening, the inner mounting thread is turned by a lathe to obtain the rough shell; the depth and spacing of the installed internal thread are adjusted according to actual needs;

[0042] S3: Preparing the fine shell, washing the inside and outside of the rough shell prepared in step S2 with high-pressure water for 10-15 seconds, and then drying it with high-temperature nitrogen at 350°C; washing with high-pressure water is to re...

Embodiment 3

[0049] A method for processing a sensor copper shell, comprising the steps of:

[0050] S1: blank shell preparation, the inner mold is placed in the cylindrical outer mold, liquid copper water is injected between the inner mold and the outer mold, and after the copper water is cooled, the inner mold and the outer mold are smashed to obtain the blank shell ; Through this step, the blank shell is obtained, and this step is prepared by a traditional method;

[0051] S2: rough shell preparation, on the inner wall of one end of the blank shell with a larger opening, the inner mounting thread is turned by a lathe to obtain the rough shell; the depth and spacing of the installed internal thread are adjusted according to actual needs;

[0052] S3: Preparing the fine shell, washing the inside and outside of the rough shell prepared in step S2 with high-pressure water for 10-15 seconds, and then drying it with high-temperature nitrogen at 400°C; washing with high-pressure water is to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com