Heat radiation method of charging pile and circulating heat radiation structure

A technology of circulating heat dissipation and heat dissipation method, applied in charging stations, electric vehicle charging technology, electric vehicles and other directions, can solve the problems of corrosion of components, achieve high protection level, reduce heat exchange efficiency, and good dehumidification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

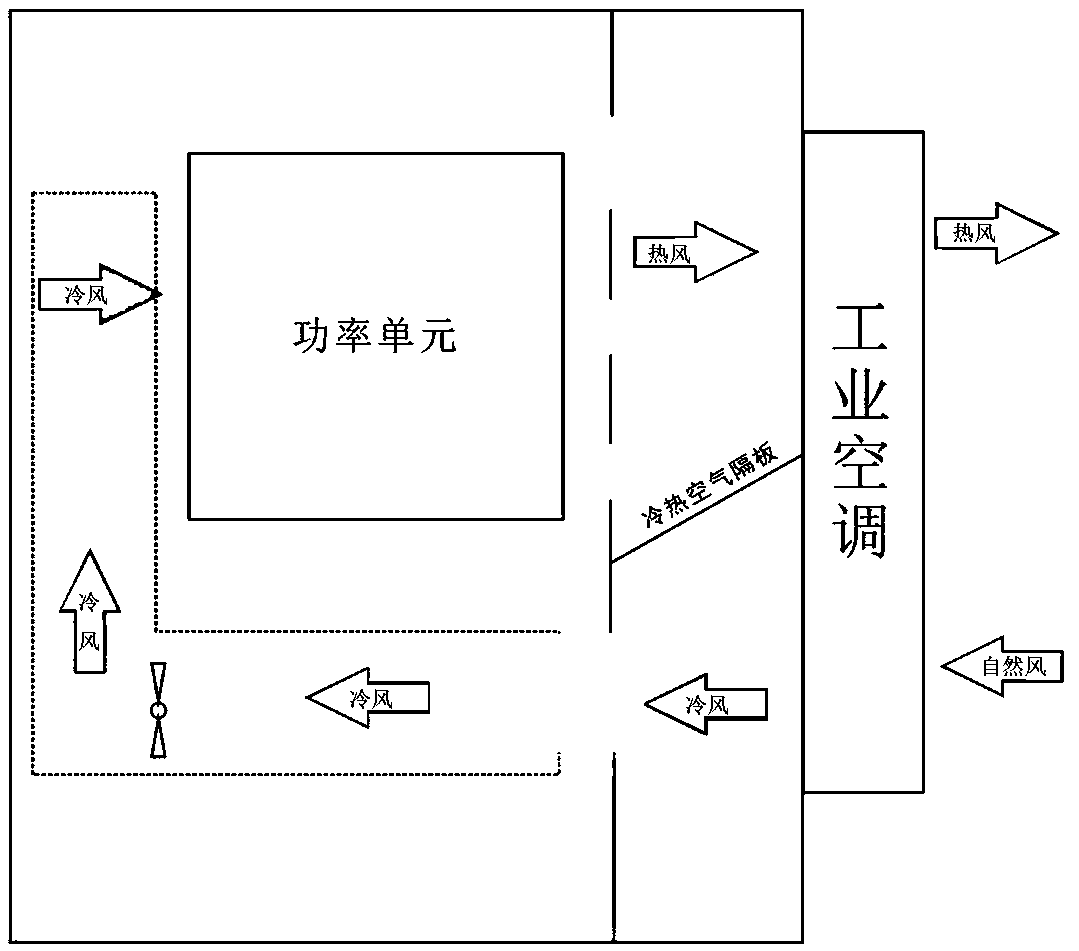

[0032] Such as figure 1 Shown: A heat dissipation method for charging piles. The interior of the charging pile cabinet is divided into a front compartment with a DC power distribution area and an AC power distribution area, and a rear compartment with a power module. The front compartment does not participate in circulating heat dissipation, and the rear compartment The warehouse is divided into two left and right chambers by the module inlet and outlet air cooling compartment and the ventilation duct compartment. The structure makes the rear warehouse form a C-shaped air duct, and the circulating air in the C-shaped air duct is used to continuously take away the heat generated by the power module, and then conducts heat exchange with the cold air generated by the industrial air conditioner to reduce the temperature of the circulating air, and the cooled circulating air is again Enter the power module through the C-shaped air duct for heat exchange. Industrial air conditioner...

Embodiment 2

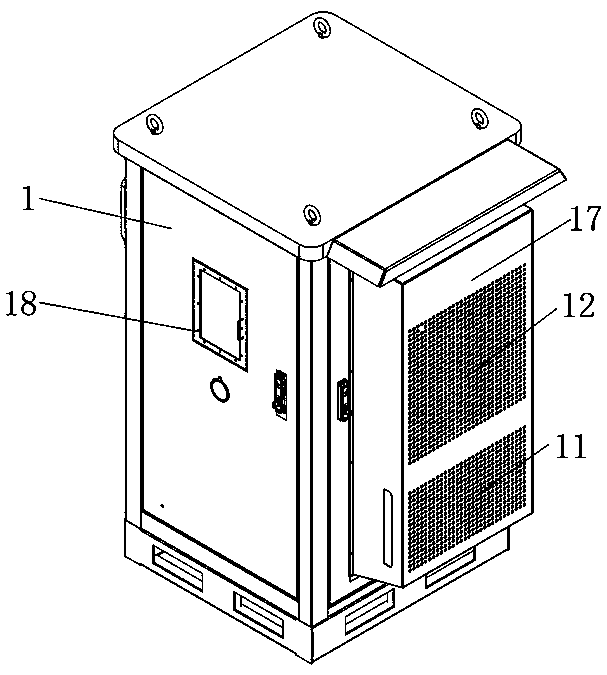

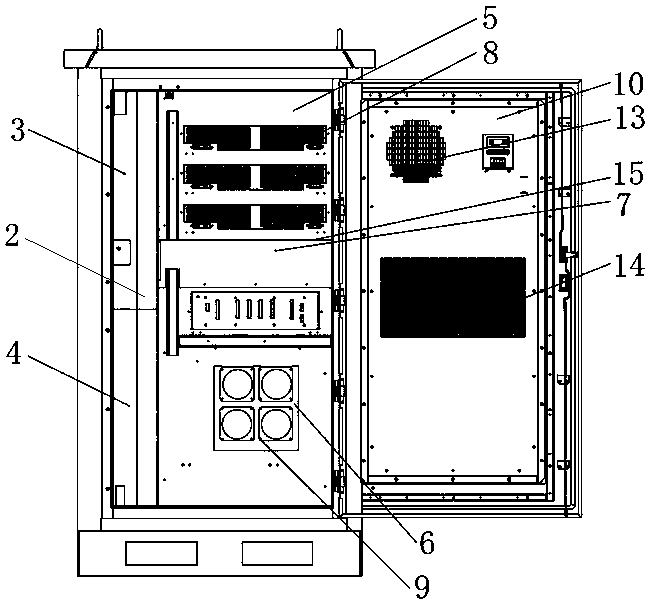

[0034] Such as Figure 2-5Shown: a heat dissipation method and circulation heat dissipation structure of a charging pile, including a cabinet body, a cabinet front door 1, and cabinet left and right doors. It is divided into a front warehouse and a rear warehouse. The front warehouse is respectively equipped with a DC power distribution area 3 and an AC power distribution area 4 from top to bottom. The DC power distribution area 3 is equipped with a control module and a metering unit. The interior of the rear compartment is divided into two chambers, left and right, by the module air inlet and outlet cooling compartment 5 and the ventilation duct compartment 6 arranged from top to bottom. The air duct dividing plate 7 of the lower chamber, the air duct dividing plate 7 is equipped with a sealing rubber strip 15, after the right side door is closed, by the extrusion of the sealing rubber strip 15, the isolation effect of the air duct dividing plate 7 is improved. Well, avoid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com