Oil storage tank top self-sealing or double-sealing combination system

A combined system and oil storage tank technology, which is applied in the field of oil storage tanks and their air sealing devices, can solve problems such as air pollution, resource waste, and exhaust emissions, and achieve the effects of safety assurance, reduced air sealing costs, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

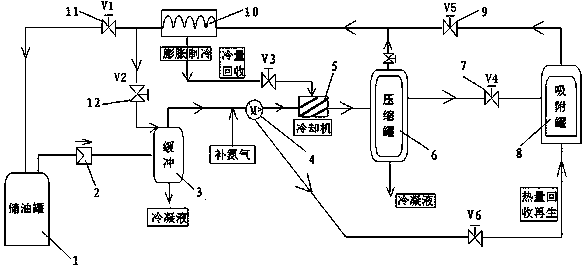

[0028] Such as figure 1 The self-sealing or double-sealing combined system on the top of the oil storage tank shown is used for gas sealing of the oil storage tank for storing oil products. The interior of the oil storage tank has a liquid space and a gas space on the top of the tank. There is a one-way valve; after the one-way valve, a compressor and a compression tank are connected, and the upper part of the compression tank has an air outlet; between the compressor and the compression tank, there is a cooling device for cooling the fluid in the pipeline; the compression tank cannot compress and condense The low boiling point gas is discharged from the gas outlet, enters the gas expansion device installed in the subsequent pipeline, and then flows into the tank top gas space of the oil storage tank through the valve V1, and the low boiling point gas becomes the filling gas of the oil storage tank.

[0029] A buffer tank may be connected between the one-way valve and the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com