Method for removing Fe<3+> and organic matters in hydrazine hydrate obtained by ketazine process

A ketazine method, hydrazine hydrate technology, applied in the directions of nitrogen and non-metallic compounds, hydrazine, etc., can solve the problems of excessive ion content and affect the appearance of hydrazine hydrate products, and achieve the effect of reducing organic content, improving quality and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

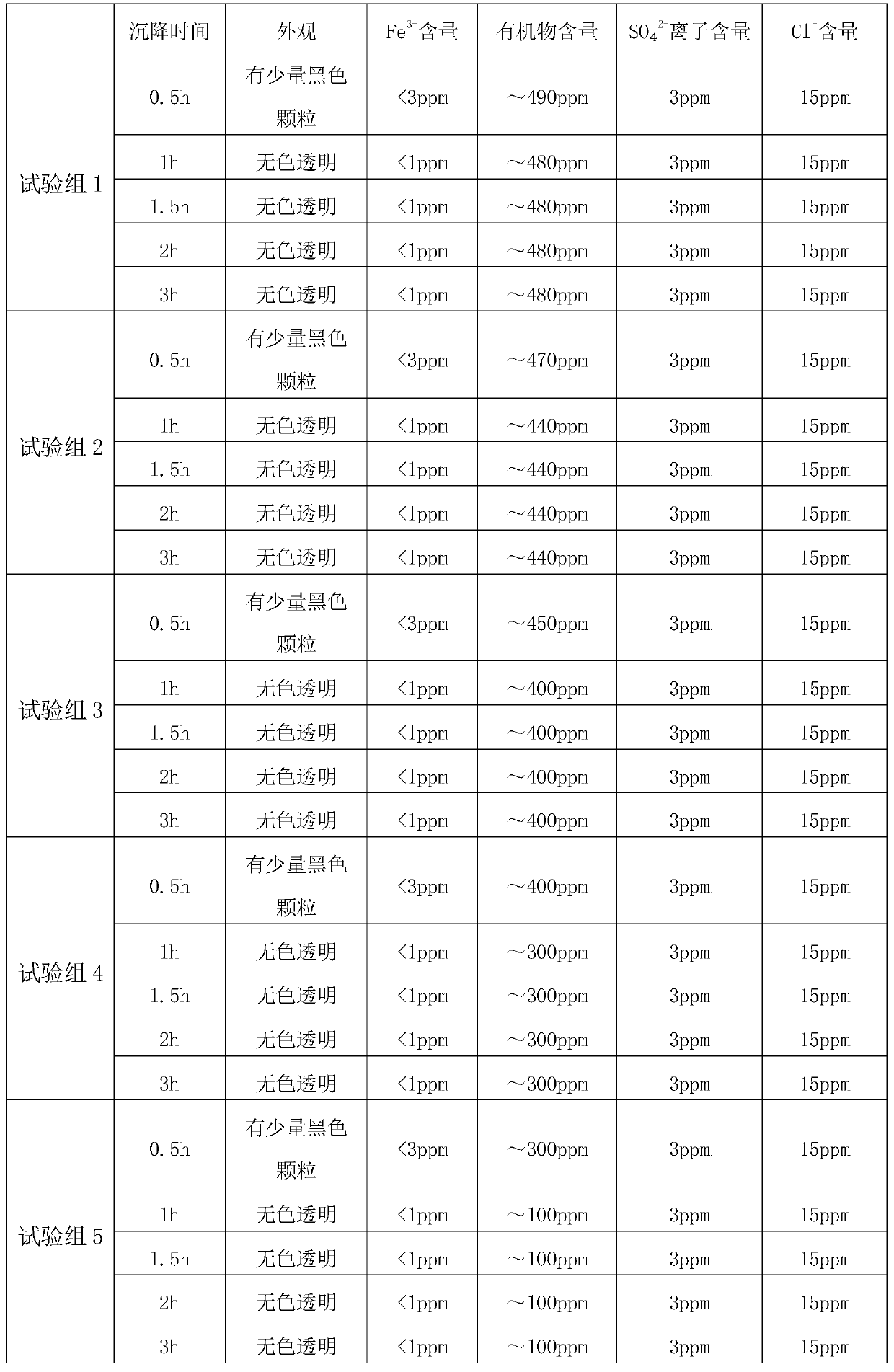

Examples

Embodiment Construction

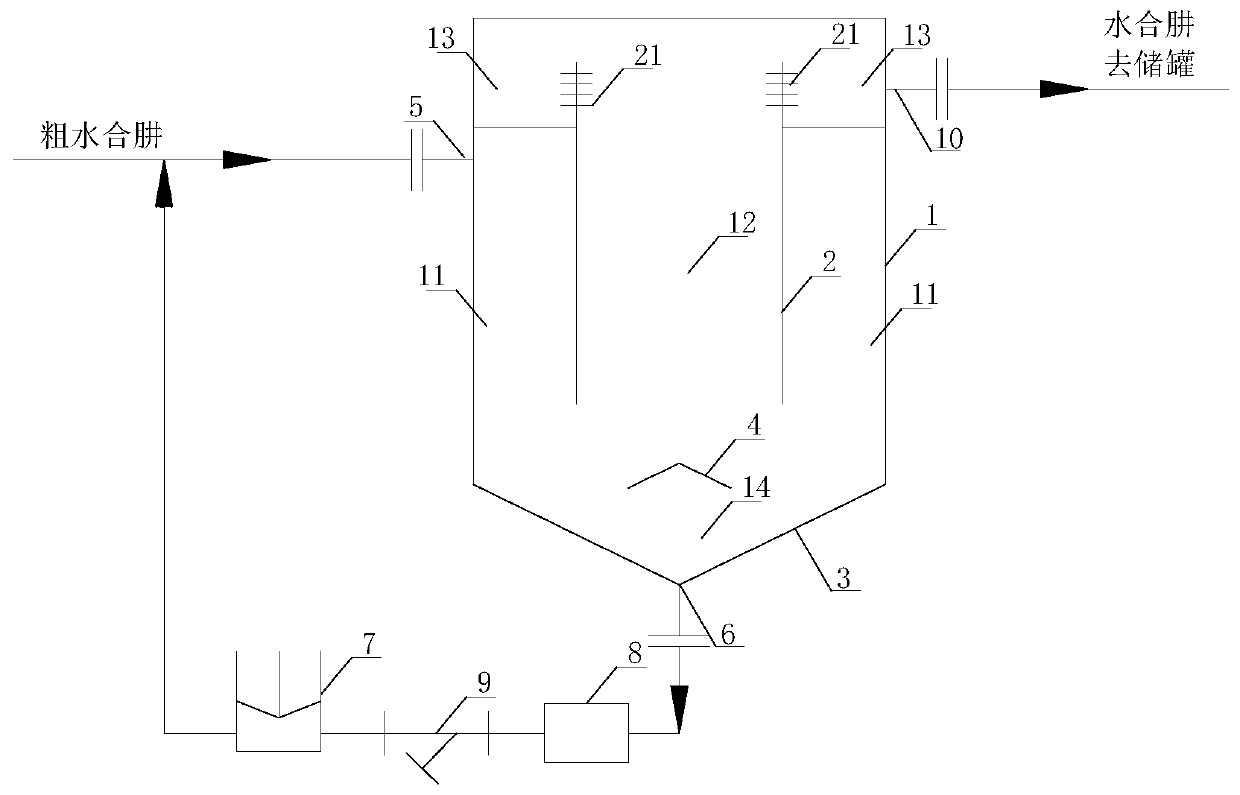

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] like figure 1 As shown, a method for removing Fe in hydrazine hydrate by ketazine method 3+ Settling tank, the settling tank includes a tank body 1, a central inner cylinder 2 and a tank bottom 3, the tank body 1 and the tank bottom 3 are connected, and the central inner cylinder 2 is coaxial with the tank body 1 and fixed vertically on In the tank body 1; the top of the central inner tube 2 is lower than the top of the tank body 1, and the top of the central inner tube 2 is connected to the side wall of the tank body 1; the bottom of the tank 3 is an inverted conical bottom; A conical flow stabilizing plate 4 is provided between the center inner cylinder 2 and the groove bottom 3, and the stabilizing device is used to fix the described flow stabilizing plate 4 between the central inner cylinder 2 and the groove bottom 3. The outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com