Method for deep removal of molybdenum in manganese sulfate solution by fresh nano-hydrated manganese oxide

A technology of manganese sulfate solution and hydrated manganese oxide, which is applied in the direction of manganese oxide/manganese hydroxide, manganese sulfate, nanotechnology, etc., can solve the problems of high cost and complicated procedures, and achieve reduced slag disposal costs, good stability, and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

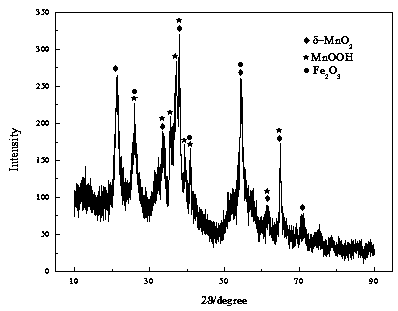

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

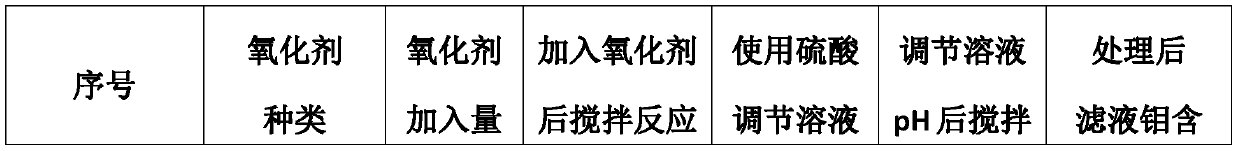

[0022] 1. The applicant carried out the following example verification by taking 100L manganese sulfate solution. After testing, the initial solution pH value = 5.5, molybdenum content = 3.51mg / l, and proceeded according to the following steps, adding an oxidizing agent to the manganese sulfate solution, adding the oxidizing agent The molar ratio of the molybdenum content to the molybdenum content in the manganese sulfate solution is 100-500:1, stirring and reacting for 10-30 minutes, the manganese ions in the manganese sulfate solution are oxidized and form new nano-manganese oxide, and the pH value of the solution is adjusted to 2- 4, filter after stirring and reacting for 10-30 minutes, the filtrate is the manganese sulfate solution after purification, carry out the following examples;

[0023]

[0024]

[0025] 2. Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com