Production equipment for liquid organic fertilizer and method

A production equipment and organic fertilizer technology, applied in the field of liquid organic fertilizer production equipment, can solve problems such as low production efficiency and environmental pollution, and achieve the effects of improving production efficiency, wide distribution range, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

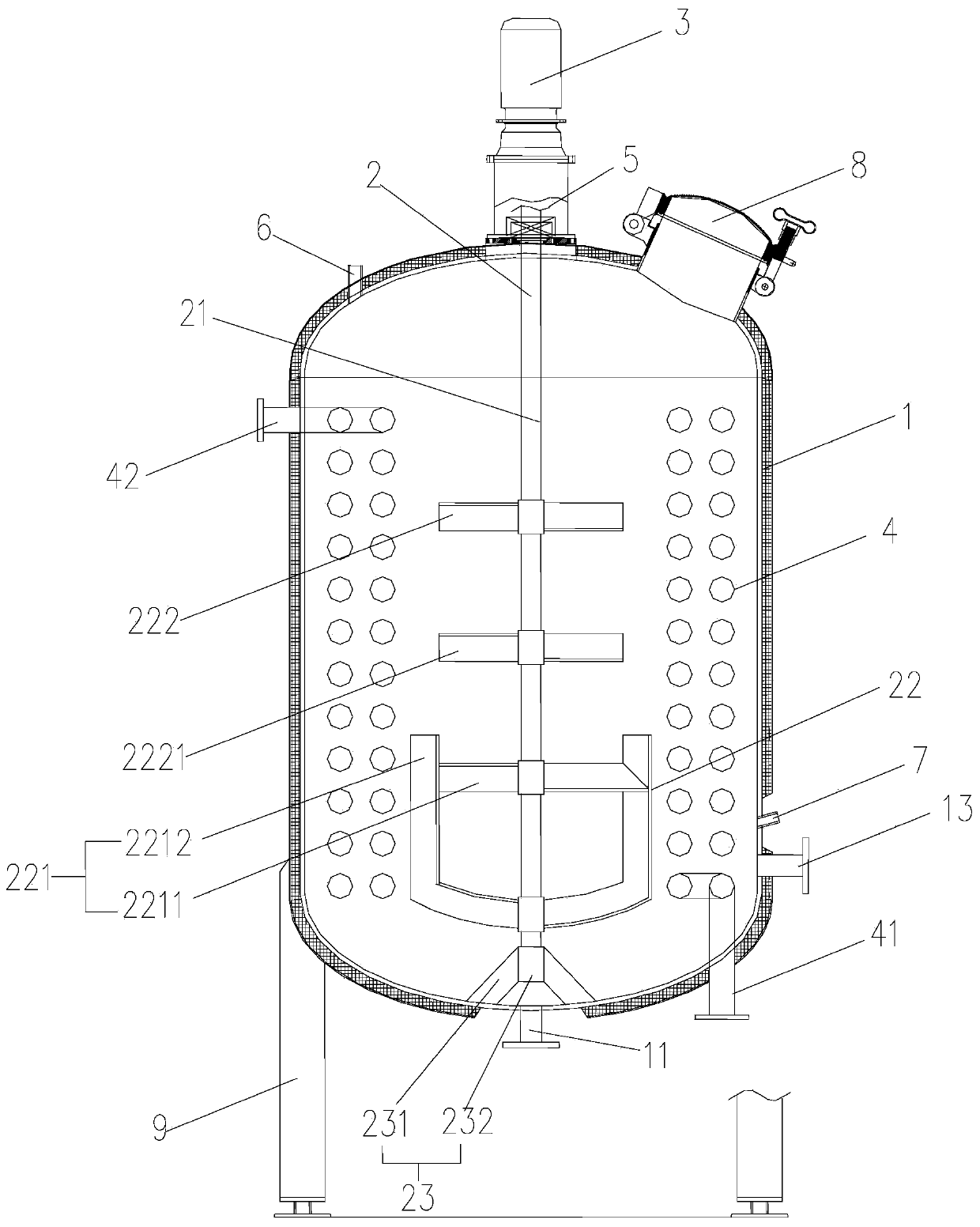

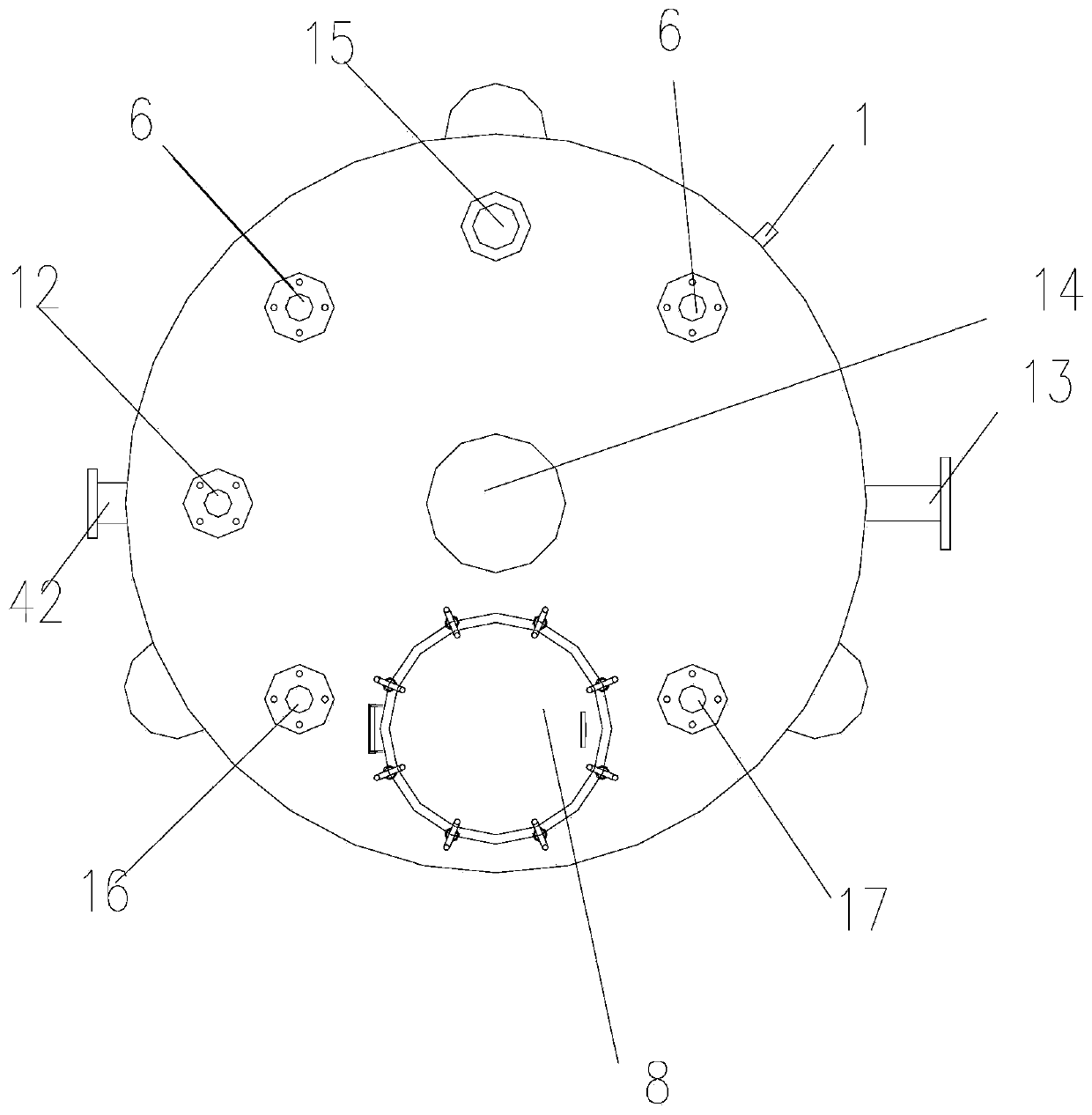

[0040] Such as Figure 1-2 Shown, a kind of liquid organic fertilizer production equipment comprises:

[0041] Tank 1,

[0042] The stirring mechanism, the stirring mechanism includes a stirring device 2 and a power mechanism 3 for driving the stirring device 2 to rotate, the power mechanism 3 is installed outside the tank body 1; the stirring device 2 is arranged in the tank body 1, and one end thereof passes through the tank body 1 The top wall of is connected to the output end of power mechanism 3;

[0043] The heat conduction coil 4 is installed in the tank body 1 and is arranged around the stirring device 2; the heat conduction medium inlet 41 and the heat conduction medium outlet 42 of the heat conduction coil 4 penetrate and protrude from the side wall of the tank body 1 respectively.

[0044]The beneficial effect of this embodiment is: the heat conduction coil 4 of this embodiment is directly arranged inside the tank body 1, and the heat conduction coil 4 is arranged...

Embodiment 2

[0046] Such as Figure 1-2 Shown, a kind of liquid organic fertilizer production equipment comprises:

[0047] Tank 1,

[0048] The stirring mechanism, the stirring mechanism includes a stirring device 2 and a power mechanism 3 for driving the stirring device 2 to rotate, the power mechanism 3 is installed outside the tank body 1; the stirring device 2 is arranged in the tank body 1, and one end thereof passes through the tank body 1 The top wall of is connected to the output end of power mechanism 3;

[0049] The heat conduction coil 4 is installed in the tank body 1 and is arranged around the stirring device 2; the heat conduction medium inlet 41 and the heat conduction medium outlet 42 of the heat conduction coil 4 penetrate and protrude from the side wall of the tank body 1 respectively.

[0050] And the heat conduction coil 4 is arranged around the stirring device, which not only realizes the purpose of wide distribution of the heat conduction coil 4, but also makes the...

Embodiment 3

[0093] A kind of liquid organic fertilizer production method, adopts above-mentioned liquid organic fertilizer production equipment to realize, comprises steps:

[0094] S1: Feeding: After adding the organic waste liquid into the tank, seal the tank;

[0095] S2: Heating and stirring: heat conduction medium is introduced into the heat conduction coil to heat the organic waste liquid in the tank, so that high temperature and high pressure are formed in the tank; at the same time, the stirring mechanism is turned on for stirring.

[0096] S3: cooling: stop heating and stirring, cool down and obtain liquid organic fertilizer.

[0097] Preferably, heating in S2 until the temperature in the tank reaches 150-200° C., and the pressure in the tank reaches 0.5-1.6 MPa; the heating time is 2-3 hours; the stirring rate is 40-60 rpm.

[0098] The beneficial effect of this embodiment is: this solution has all the beneficial effects of the above-mentioned liquid organic fertilizer producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com