Regenerated powder concrete with good durability, and preparation method thereof

A technology of recycled concrete and recycled powder, which is applied in the field of concrete preparation, can solve problems such as the decline in mechanical properties and durability of concrete structures, and corrosion of steel bars, so as to reduce the amount of cement, increase the amount, and optimize the ability to resist chloride ion erosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

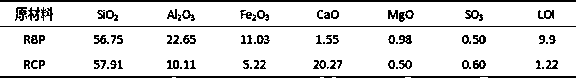

[0024] The preparation method of recycled concrete powder: when the discarded old concrete blocks are broken into recycled aggregates, the powder produced in the crushing process is collected, and the powder with a particle size below 0.6mm is screened out for use, and put into four Recycled concrete powder is prepared by grinding steel balls of different sizes and steel forgings in SM-500 ball mill, and its specific surface area is 863m 2 / kg, the particle size is less than 5μm accounted for 18.38%, 5-10μm accounted for 11.66%, 10-20μm accounted for 14.51%, 20-45μm accounted for 25.31%, 45-100μm accounted for 17.21%, 100-160μm accounted for 8.21%, 160-250μm Accounting for 4.72%, the 28d activity index of recycled concrete powder is 80%. The chemical composition is shown in Table 1.

[0025] The preparation method of regenerated brick powder: remove the old mortar attached to the surface of the waste clay brick and then crush it, collect the powder generated during the crushi...

example 1

[0040] A recycled powder concrete, which is prepared by cement, recycled brick powder, water, sand, natural aggregate, and water reducer at a mass ratio of 1:0.111:0.444:1.652:2.694:0.002. Recycled brick powder 10% and other quality to replace cement.

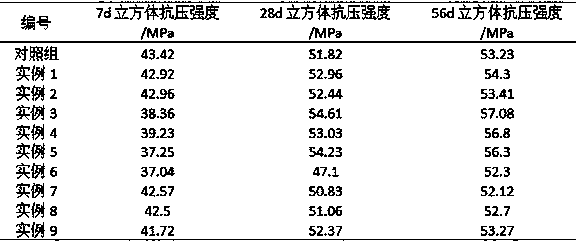

[0041] According to the "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" (GB50081-2002), the recycled powder concrete of the present invention has a 7d cube compressive strength of 42.92MPa, a 28d cube compressive strength of 52.96MPa, and a 56d cube compressive strength of 53.30MPa. The slump is 160mm.

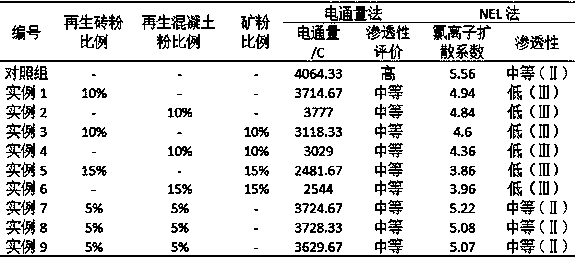

[0042] For the recycled powder concrete of the present invention, the ASTMC1202 method and the NEL method are used to evaluate its resistance to chloride ion penetration. The electric flux of the concrete tested by ASTMC1202 method is 3714.67C, and the permeability evaluation is medium; the anti-chloride ion diffusion coefficient measured by NEL method is 4.94, and the permeability evaluation is low (...

example 2

[0044] A recycled powder concrete, which is prepared by cement, recycled concrete powder, water, sand, natural aggregate, and water reducer at a mass ratio of 1:0.111:0.444:1.652:2.694:0.001. Recycled concrete powder 10% and other quality to replace cement.

[0045] According to the "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" (GB50081-2002), the recycled powder concrete of the present invention has a 7d cube compressive strength of 42.96MPa, a 28d cube compressive strength of 52.44MPa, and a 56d cube compressive strength of 53.23MPa. The slump is 155mm.

[0046] For the recycled powder concrete of the present invention, the ASTMC1202 method and the NEL method are used to evaluate its resistance to chloride ion penetration. The electric flux of the concrete tested by ASTMC1202 method is 3777C, and the permeability evaluation is medium; the anti-chloride ion diffusion coefficient measured by NEL method is 4.84, and the permeability evaluation is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com