Method for basic oil adsorption treatment with silica gel and silica gel regeneration and recycling

A technology of adsorption treatment and base oil, which is applied in the direction of hydrocarbon oil treatment products, hydrocarbon oil treatment, hydrogenation treatment process, etc., can solve the problems of poor oxidation stability of oil products, and achieve the effect of good oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

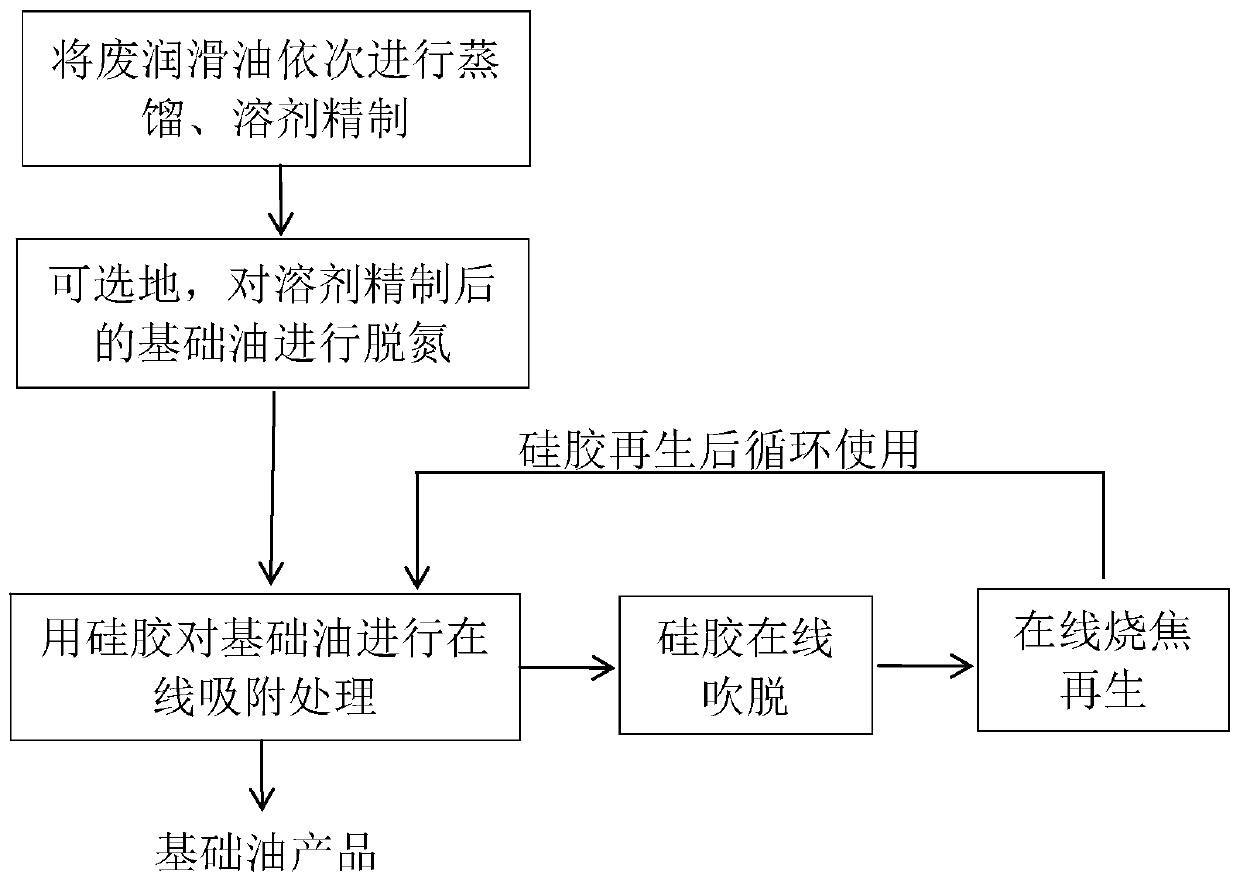

Image

Examples

Embodiment 1

[0066] This example is used to illustrate the waste lubricating oil regeneration method provided by the present invention.

[0067] The waste lubricating oil (provided by Anhui Guofu Lubricating Oil Company) was subjected to vacuum distillation, and then solvent refined with nitrogen methyl pyrrolidone.

[0068] Under stirring, the base oil after the solvent refining was mixed with WSQ-2 denitrification agent (purchased from Wuhan Hannan Jinhe Petrochemical Co., Ltd.) for denitrification treatment. The denitrification temperature was 90° C. and the time was 40 min. The agent-to-oil ratio is 1:300.

[0069] The base oil obtained after denitrification is injected into a fixed-bed adsorption tower filled with silica gel for adsorption treatment. The silica gel has a particle size of 1-3 mm and an average pore size of 9.97 nm, provided by Qingdao Xinchanglai Silica Gel Co., Ltd. The temperature of the adsorption treatment is 120°C, and the space velocity is 1.5h -1 .

[0070] W...

Embodiment 2

[0073] This example is used to illustrate the waste lubricating oil regeneration method provided by the present invention.

[0074] The waste lubricating oil (provided by Anhui Guofu Lubricating Oil Company) was subjected to vacuum distillation, and then solvent refined with nitrogen methyl pyrrolidone.

[0075] Under stirring, the base oil after the solvent refining was mixed with WSQ-2 denitrification agent (purchased from Wuhan Hannan Jinhe Petrochemical Co., Ltd.) for denitrification treatment. The denitrification temperature was 90° C. and the time was 40 min. The agent-to-oil ratio is 1:300.

[0076] The base oil obtained after denitrification is injected into a fixed-bed adsorption tower filled with silica gel for adsorption treatment. The silica gel has a particle size of 1-3mm and an average pore size of 7.62nm, provided by Qingdao Xinchanglai Silica Gel Co., Ltd. The temperature of the adsorption treatment is 100°C, and the space velocity is 1h -1 .

[0077] When ...

Embodiment 3

[0080] This example is used to illustrate the waste lubricating oil regeneration method provided by the present invention.

[0081] The waste lubricating oil (provided by Anhui Guofu Lubricating Oil Company) was subjected to vacuum distillation, and then solvent refined with nitrogen methyl pyrrolidone.

[0082] Under stirring, the base oil after the solvent refining was mixed with WSQ-2 denitrification agent (purchased from Wuhan Hannan Jinhe Petrochemical Co., Ltd.) for denitrification treatment. The denitrification temperature was 90° C. and the time was 40 min. The agent-to-oil ratio is 1:300.

[0083] The base oil obtained after denitrification is injected into a fixed-bed adsorption tower filled with silica gel for adsorption treatment. The silica gel has a particle size of 1-3mm and an average pore size of 13.02nm, provided by Qingdao Xinchanglai Silica Gel Co., Ltd. The temperature of the adsorption treatment is 160°C, and the space velocity is 2h -1 .

[0084] When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com