Waste-lubricant regeneration and diesel production device

A technology for waste lubricating oil and diesel oil, applied in lubricating compositions, hydrocarbon oil treatment products, treatment of hydrocarbon oil, etc., can solve the problems of low recovery rate, large amount of waste of resources, environmental pollution, etc., and achieve high recovery rate and oil quality. The effect of good quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

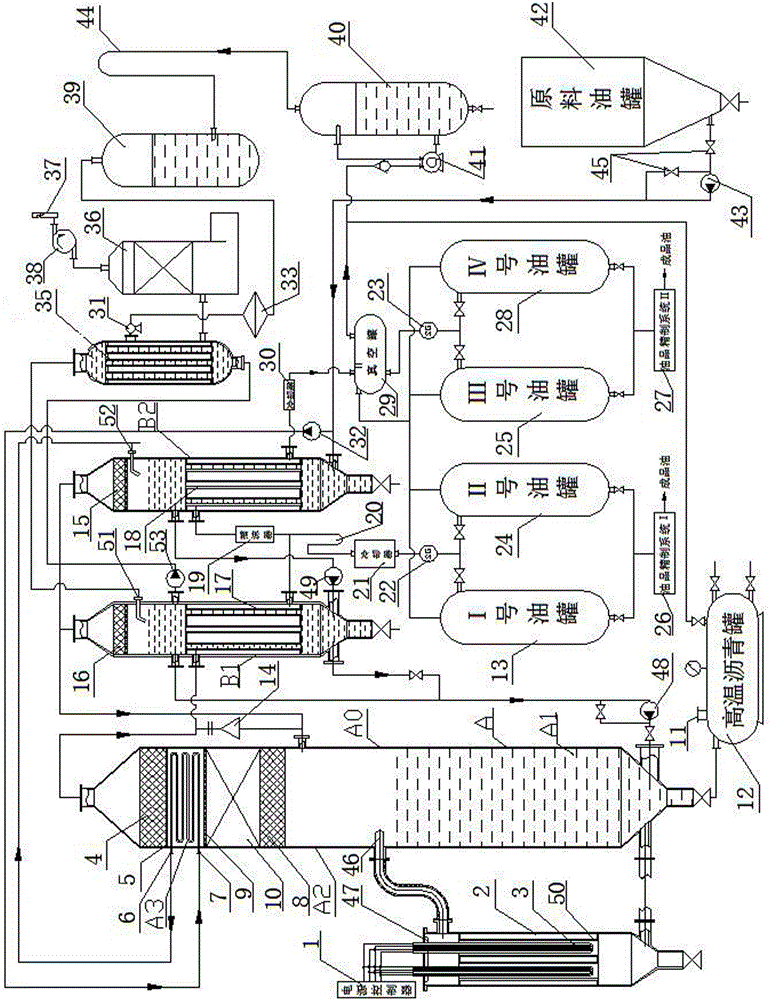

[0017] As shown in the figure, the waste lubricating oil regeneration and diesel production device mainly consists of evaporation catalyst A, preheating fractionator B1, preheating fractionator B2, heat recovery device 35, desulfurizer 36, flame arrester 39, vacuum asphalt tank 12 , a raw material tank 42, a vacuum pump 41, a burner 31 and an oil refining system. The oil outlet of the raw material tank 42 is connected to the oil inlet I of the preheating fractionator B2, and the oil outlet of the preheating fractionator B2 is connected to the preheating fractionator B2. The oil inlet of the raw material oil preheating chamber of the fractionator B1 is connected through the pump I49, and the outlet of the raw material oil preheating chamber of the preheating fractionator B1 is connected with the oil inlet of the evaporation catalytic converter A, and the preheating fractionator B1, preheating The oil and gas outlet of the fractionator B2 is connected in parallel with the oil and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com