Anthracene oil hydrogenation reaction system and method

A reaction system and hydrogenation reaction technology, applied in the fields of hydrogenation treatment process, chemical instruments and methods, petroleum industry, etc., can solve the problems of high pressure, low production capacity, and high energy consumption of hydrogenation reactors, and achieve high liquid hourly space velocity , Reduce energy consumption, low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

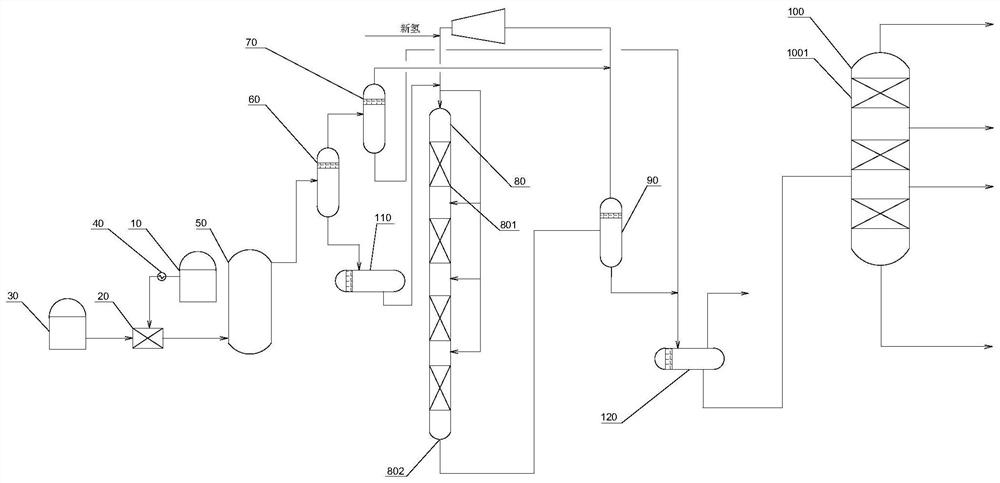

[0058] refer to figure 1 Shown is a reaction system for hydrogenation of anthracene oil according to an embodiment of the present invention, which mainly includes a micro-interface generator 20, a hydrogenation reactor 50, and a cracking reaction tower 80;

[0059] Hydrogen gas and anthracene oil are fed into the micro-interface generator 20 at the same time. The anthracene oil is transported from the anthracene oil storage tank 30, and the hydrogen gas is transported from the hydrogen storage tank 10. In the process, after the hydrogen gas is dispersed and crushed into small molecules in the micro-interface generator 20, the dispersed and crushed anthracene oil and hydrogen mixture are jointly transported to the hydrogenation reactor 50 for hydrogenation reaction;

[0060] The oil after hydrodesulfurization and denitrogenation comes out of the hydrogenation reactor 50 and is separated into hot high-separation gas and hot high-separation oil through the first separation tank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com