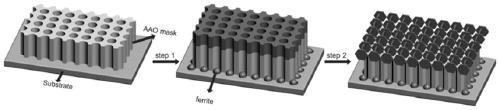

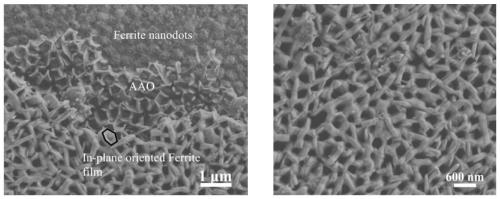

Method for preparing BaM ferrite nano-film of two-dimensional net-shaped structure and with c-axis in-plane orientation based on AAO template

A two-dimensional network, nano-film technology, applied in nanotechnology, chemical instruments and methods, iron compounds, etc., to achieve multi-selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0039] (1) Orient the crystal to (0001) Al 2 o 3 The substrate was ultrasonically cleaned in acetone solution for 10 min, then in absolute ethanol solution for 10 min, and finally in deionized water for 10 min, and dried with nitrogen.

[0040] (2) Al 2 o 3 Immerse the substrate in absolute ethanol and take it out after 1 min. When the ethanol is not completely volatilized, attach the through-hole AAO template on the substrate and let it dry; then, use a glass rod to dip a very small amount of ethanol and drop it onto the substrate without the template. Area of Al 2 o 3 On the substrate, let the ethanol diffuse spontaneously to the template area, and let it dry; repeat 2 times.

[0041] (3) Put the substrate transferred in step (2) into an oven and bake for a certain period of time. The oven temperature is 90°C, and the drying time is 2 minutes; take it out and let it cool down to room temperature.

[0042] (4) Put the sample processed in step (3) into the PLD chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com