Temperature equalizing plate and manufacturing method thereof

A manufacturing method and technology of a temperature equalizing plate, which are applied in the structural parts of electrical equipment, cooling/ventilation/heating renovation, electrical components, etc. Heat dissipation efficiency, the effect of avoiding oxidation and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] For the convenience of description, the structures, structures or parts of the vapor chamber in the drawings of the present invention are not in proportion to their application, but need to be magnified in different proportions according to the description, but this is not intended to limit the implementation of the vapor chamber of the present invention.

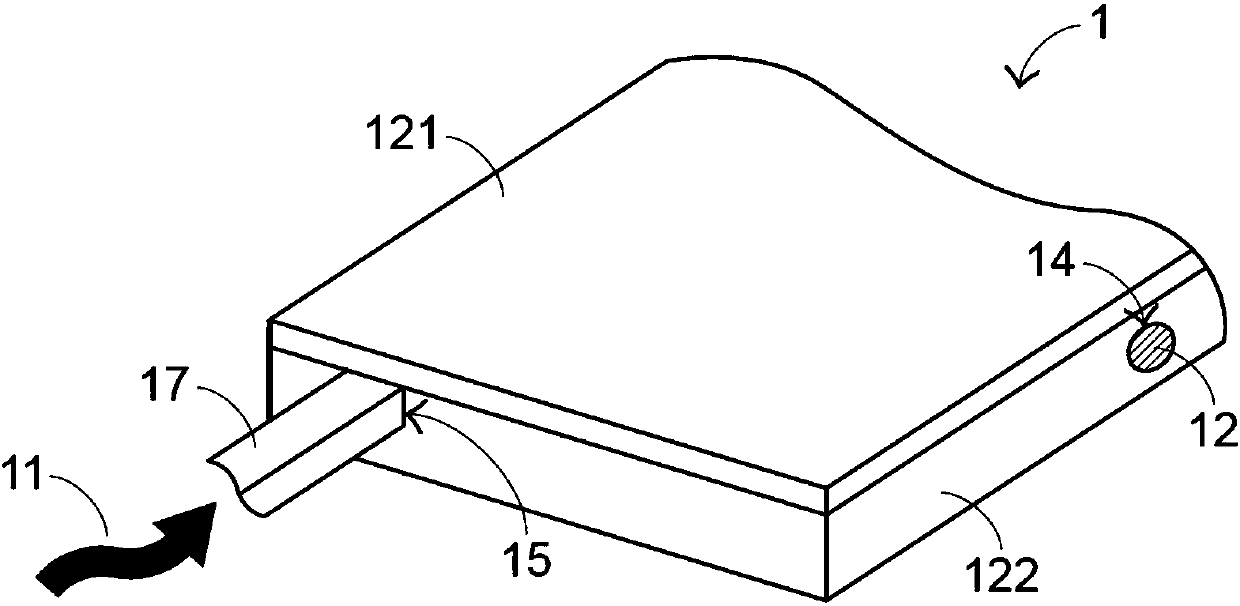

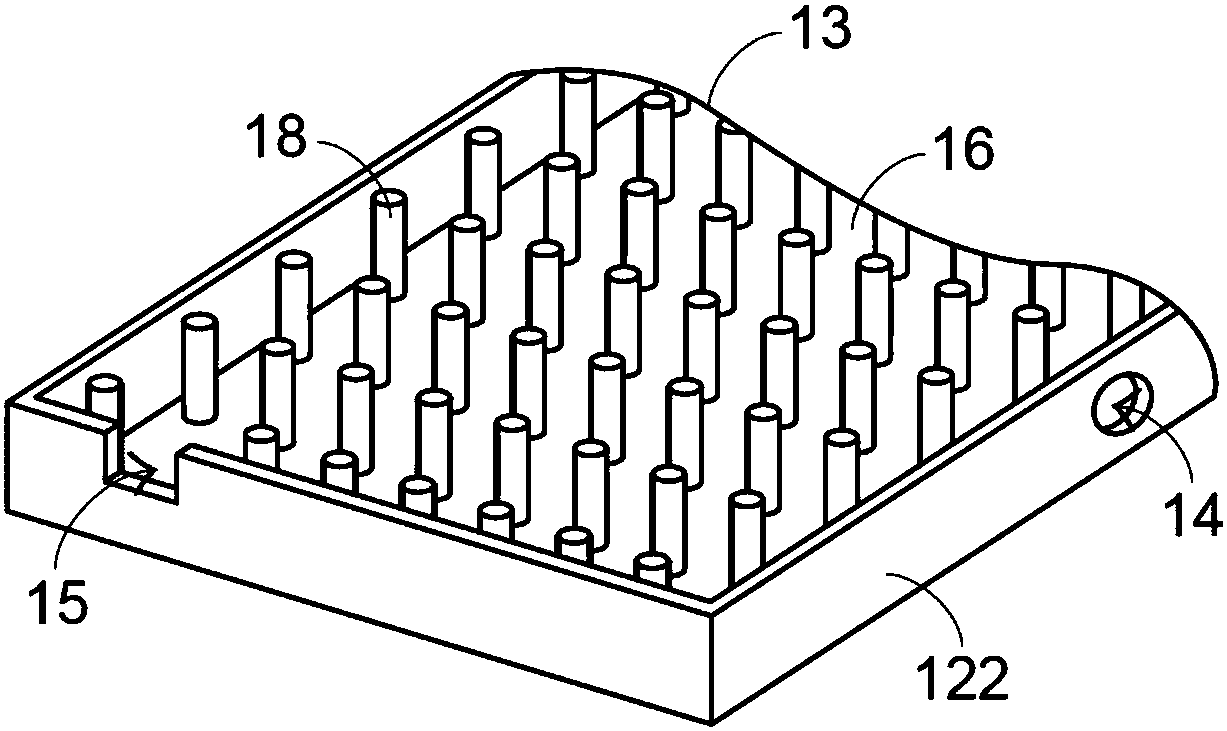

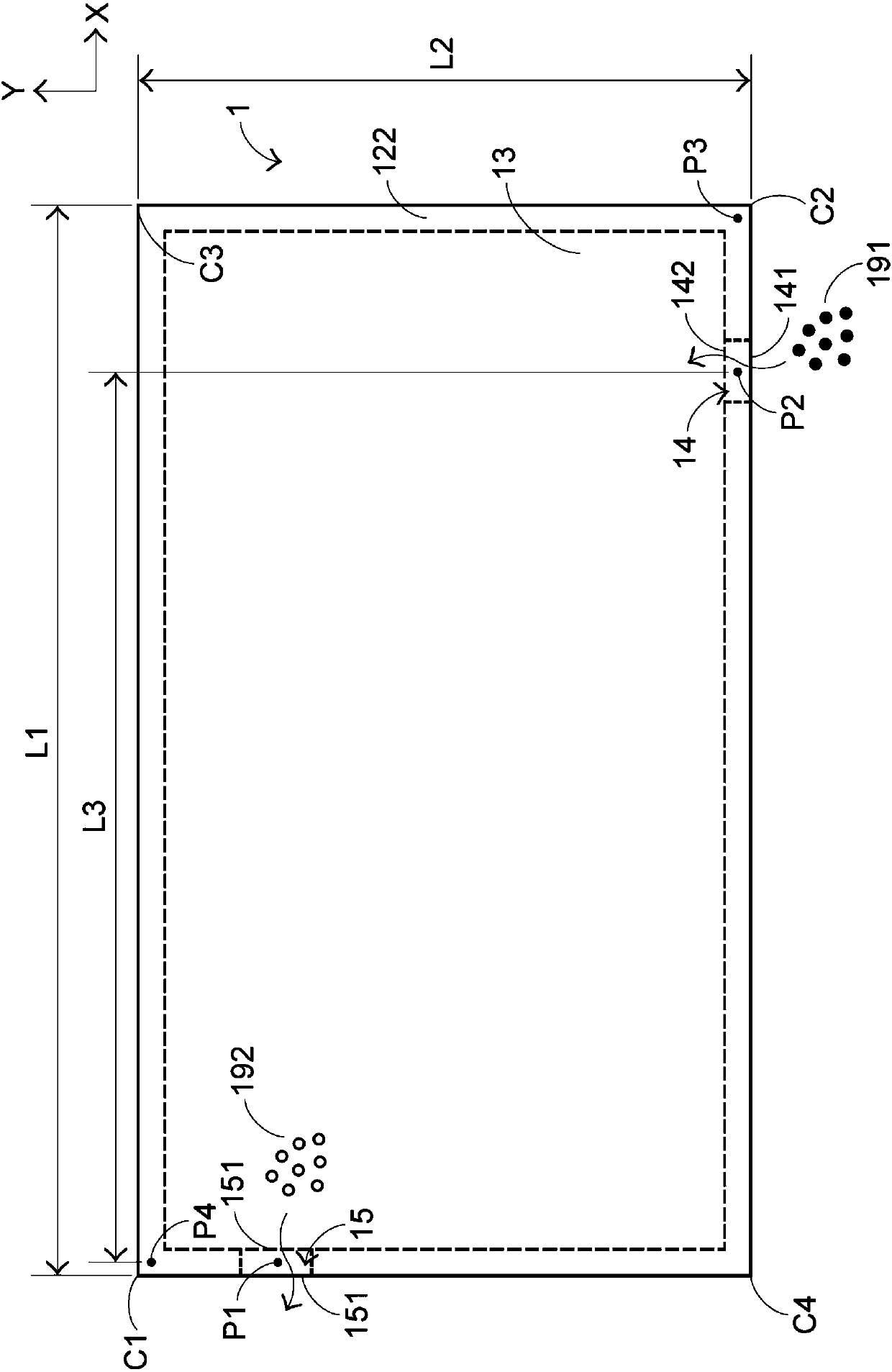

[0043] see Figure 1 ~ Figure 3 , figure 1 It is a schematic diagram of the appearance structure of a first preferred embodiment of the vapor chamber of the present invention, figure 2 for figure 1 The partial structural schematic diagram of the vapor chamber shown, image 3 for figure 1 The top view conceptual schematic diagram of the partial structure of the vapor chamber shown. For clarity, figure 2 and image 3Components such as the upper plate are not shown in the figure. The vapor chamber 1 includes an upper plate body 121 and a lower plate body 122, both of which together form a chamber 13, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com