Working face multi-source methane prediction method based on carbon and hydrogen isotopes

A mining face, carbon and hydrogen isotope technology, applied in the direction of gas discharge, mining equipment, earth drilling and mining, etc., there are not many studies that can solve the multi-source gas migration law, cannot accurately and quantitatively predict gas, and cannot specifically quantify multiple sources Issues such as the source and proportion of gas gushing out, to achieve wide application prospects, avoid blind governance and unnecessary investment, and achieve obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

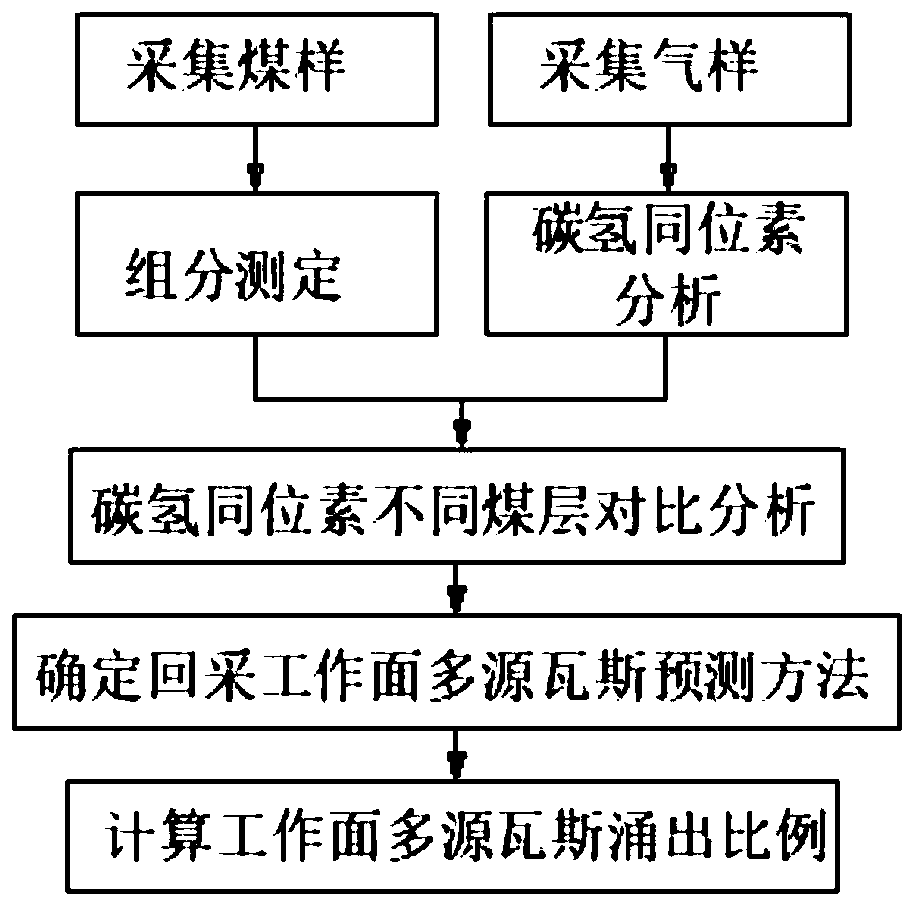

[0027] Such as figure 1 As shown, a multi-source gas prediction method based on carbon and hydrogen isotopes in the mining face belongs to a method of gas emission prediction in the working face. Calculate the output ratio, including the following steps:

[0028] S1: Obtain the first coal sample and the first gas sample respectively in the currently mined coal seam, respectively obtain the second coal sample and the second gas sample in the upper adjacent coal seam of the currently mined coal seam, and respectively obtain the second coal sample and the second gas sample in the lower adjacent coal seam of the currently mined coal seam. Obtain the third coal sample and the third gas sample, obtain the fourth gas sample in the goaf of the working face of the coal seam currently mined or obtain the fifth gas sample in the air return lane of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com