A multi-axis servo variable-proportion cooperative control method based on sliding mode variable structure

A sliding mode variable structure and cooperative control technology, applied in multiple motor speed/torque control, control systems, control generators, etc., can solve problems such as deviation and poor variable ratio synchronization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

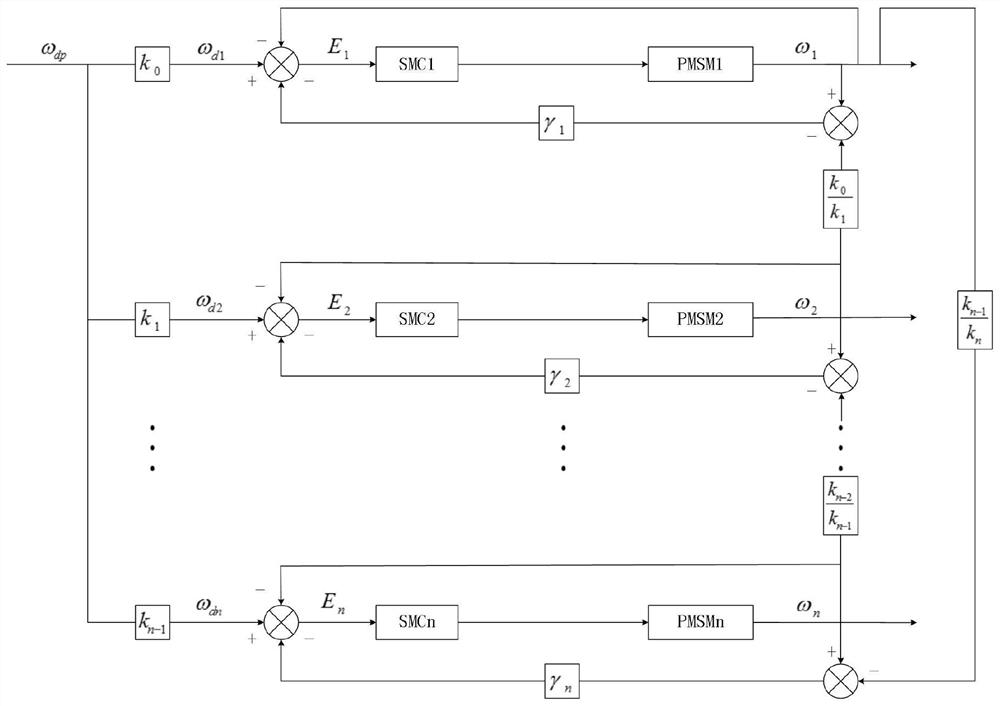

[0072] see Figure 1-5 , a multi-axis servo variable ratio cooperative control method based on sliding mode variable structure, including the following steps:

[0073] The first step is to design an improved ring-coupling control structure based on the traditional ring-coupling control structure. The purpose is to make the system meet the complex working conditions of variable ratios of motor speeds.

[0074] Further, the improved ring coupling control structure is adopted to obtain the tracking error of each motor itself;

[0075] Specifically, the tracking error of the jth motor in the system itself can be expressed as:

[0076] e j =k j-1 ω d -ω j = ω dj -ω j (1)

[0077] where k j-1 Represents the proportional coefficient between the jth motor of the system and the given speed of the system, where (j=1,2,...,n), ω dj and ω j Represent the input speed and output speed of the jth motor, respectively.

[0078] Further, calculate the tracking error of each motor a...

Embodiment 2

[0134] see Figure 1-5 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that in order to effectively reduce the chattering problem caused by the control system, the function to replace the function sgn(s j ), where δ is a normal number with a smaller value.

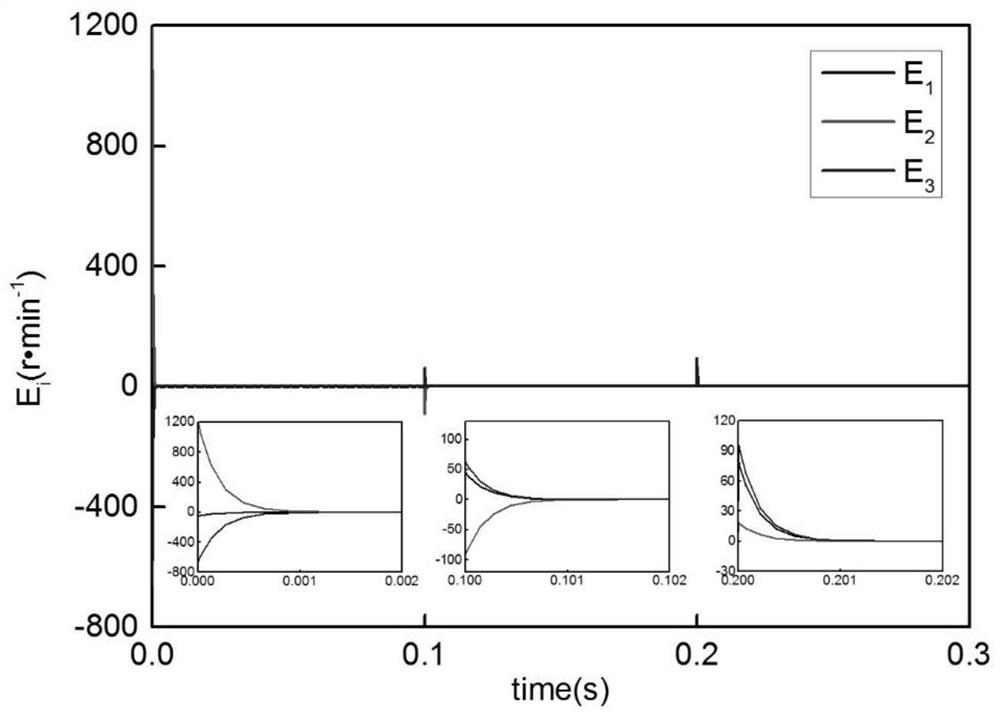

[0135] Depend on figure 2 The simulation results in Fig. 1 show that the tracking error of each motor after compensation converges to zero after about 0.001 second in each sampling period, indicating that the designed controller makes the system have a strong self-regulating ability.

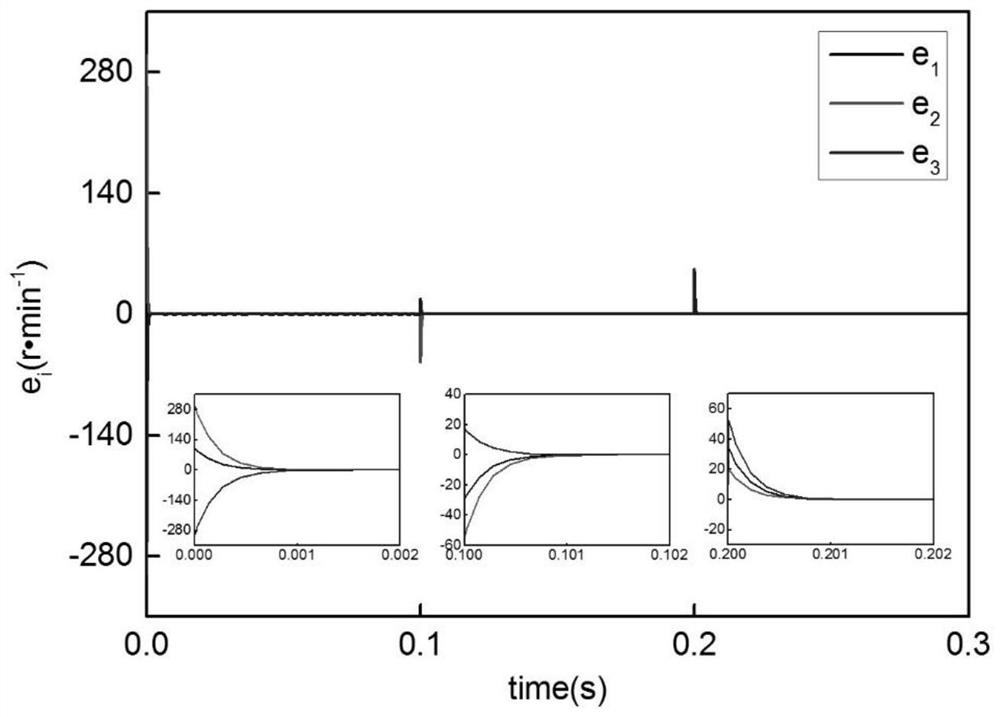

[0136] Depend on image 3 From the simulation results in , it can be seen that the tracking error of each motor converges to zero within 0.0015 seconds in each sampling period, indicating that the system has a fast dynamic response characteristic in the whole process.

[0137] Depend on Figure 4 From the simulation results in , it can be seen that the synchronization error between each mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com