A kind of automatic central kitchen and cooking device

A rice cooking device and rice cooker technology, applied in kitchen utensils, packaging, transportation and packaging, etc., can solve the problems of low operating efficiency, waste of time, and long waiting time for dining in restaurants, so as to improve the efficiency of taking meals, ensure consistency, The effect of reducing labor costs and rent operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

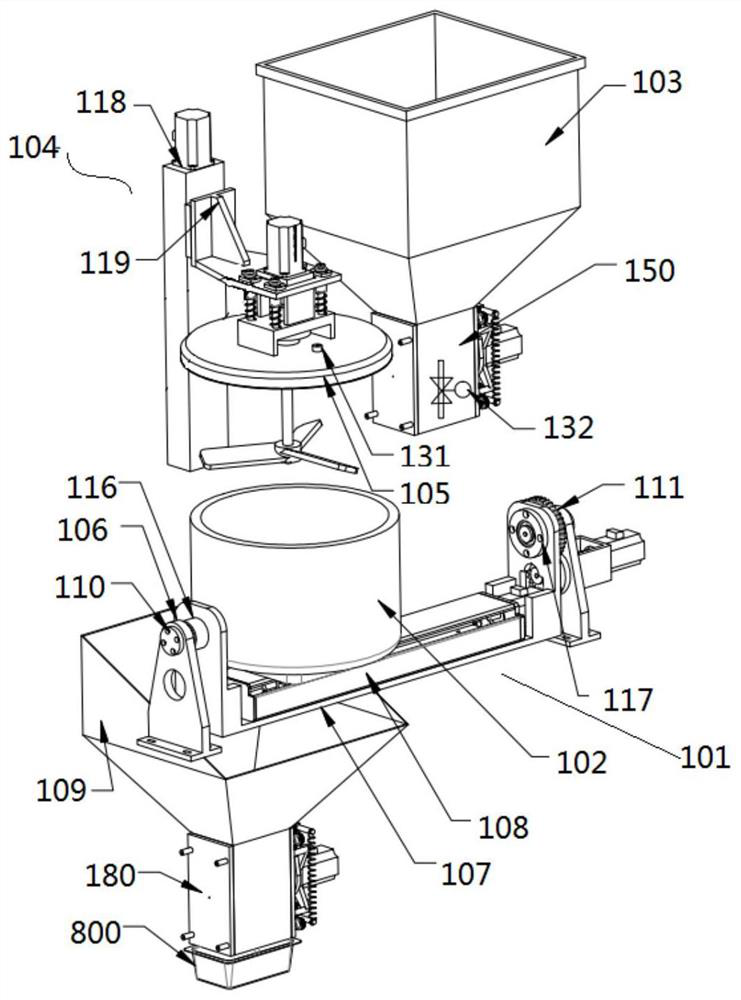

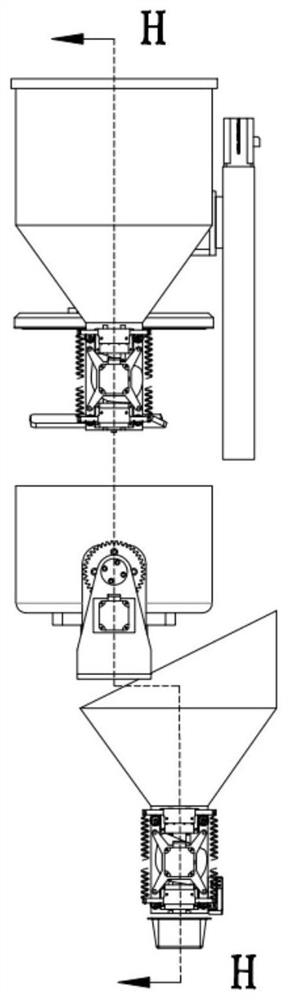

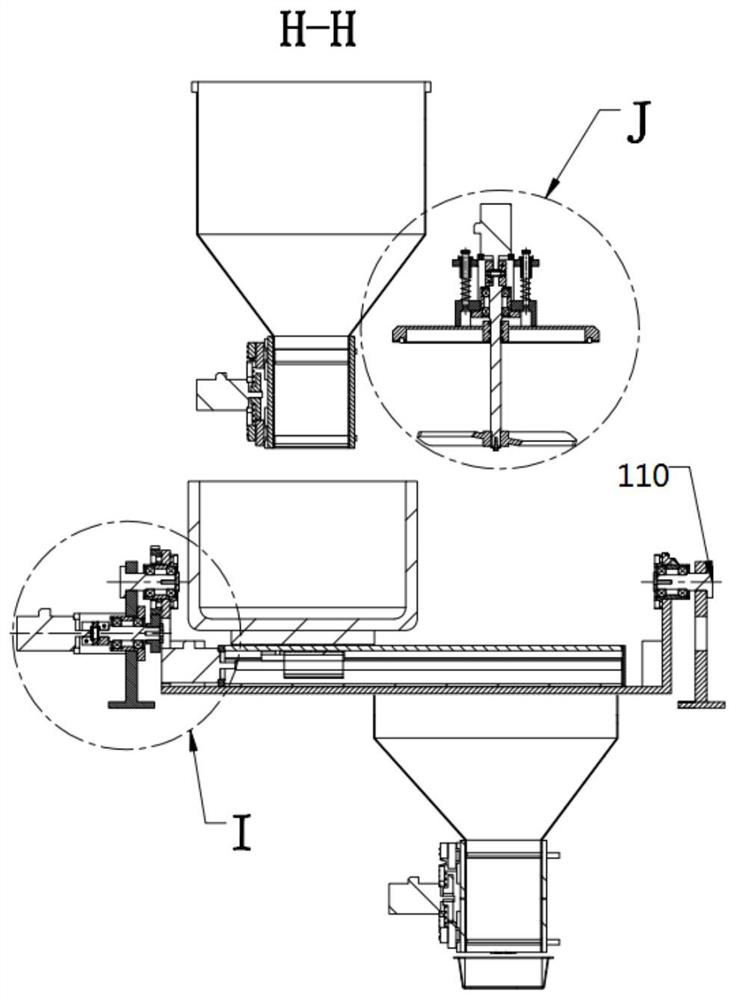

[0095] like Figure 1~Figure 5 As shown, a rice cooking device includes a turning mechanism 101, a rice cooker 102, a funnel 103, a lifting mechanism 104, and a sealing cover 105. The turning mechanism 101 includes a fixing bracket 106 and a turning bracket 107. The turning bracket 107 is connected with the fixed bracket 107. The bracket 106 is rotatably connected, the flip bracket 107 is provided with a traverse module 108, the rice cooker 102 is located on the traverse module 108, the funnel 103 and the sealing cover 105 are juxtaposed on the top of the rice cooker 102, and the sealing cover 105 is connected to the lifting mechanism 104, and a finished product hopper 109 is provided below the rice cooker 102. The traverse module 108 adopts the traverse module 108 of the prior art. Among them, the rice cooker 102 can be a common large-scale smart pot, and the inner pot is fixed with the pot body. It has the functions of cooking rice, porridge, soup, stew, stew and so on.

...

Embodiment 2

[0108] like Image 6 and Figure 7 As shown, on the basis of Embodiment 1, the food distribution mechanism includes a distribution box 151 connected to the lower part of the funnel 103, the upper end of the distribution box 151 is provided with an upper valve mechanism 152, and the lower end of the distribution box 151 is provided with The lower valve mechanism 153, the upper valve mechanism 152 and the lower valve mechanism 153 all include oppositely arranged rotatable valve plates 154 and slide plates 155, the two sides of the slide plate 155 are connected to the valve racks 156, and each valve plate 154 is Including valve shafts 157 located on the outside, each valve shaft 157 is connected with a valve gear 158, and the valve gear 158 is meshed with the valve rack 156;

[0109] A cam mechanism 159 is provided between the upper valve mechanism 152 and the lower valve mechanism 153. The cam mechanism 159 includes a cam motor 160, a cam 161, an upper spring hanging plate 162 ...

Embodiment 3

[0116] On the basis of Example 2, as Figure 8 and Figure 9As shown, the present invention also discloses a central kitchen system, which includes a rack 900, and the rack 900 is provided with a material preparation device 200, a storage device 300, a cooking machine 400, and the rice cooking device described in any one of the above. 100. A lunch box device 500 and a conveying device 600, the conveying device 600 is located below the material preparation device 200, the storage device 300, the cooking machine 400, the rice cooking device 100, and the lunch box device 500; the conveying device 600 comprises a conveying line, The conveying line conveys the lunch box 800 separated by the lunch box device 500 to the rice cooking device 100 and the meal box after the rice and vegetables are distributed under the cooking machine 400 and transported to the material preparation device 200 or the storage device 300 . Among them, the cooking machine 400 adopts the common large-scale c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com