Heat reflux extraction and concentration equipment and technology

A heat reflux and equipment technology, which is used in solid solvent extraction, essential oils/flavors, and devices for making medicines into special physical or taking forms, etc., can solve the problem of easy decomposition of active ingredients, achieve stable extraction, and improve extraction Utilization, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

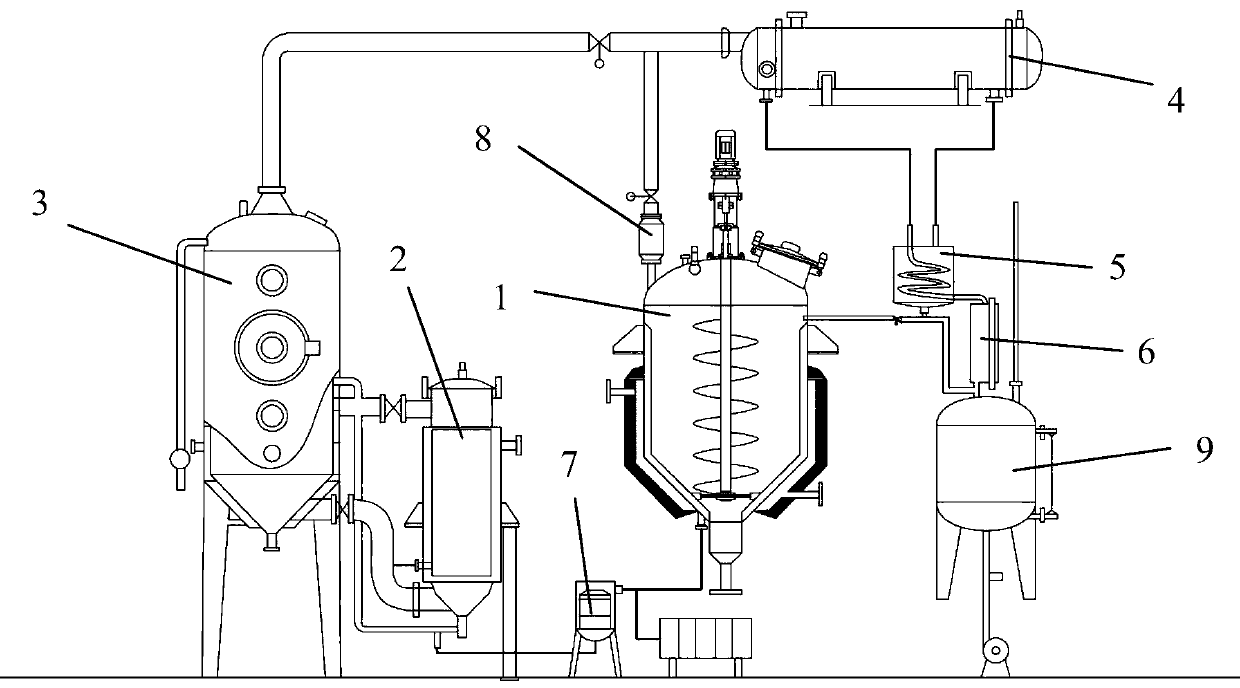

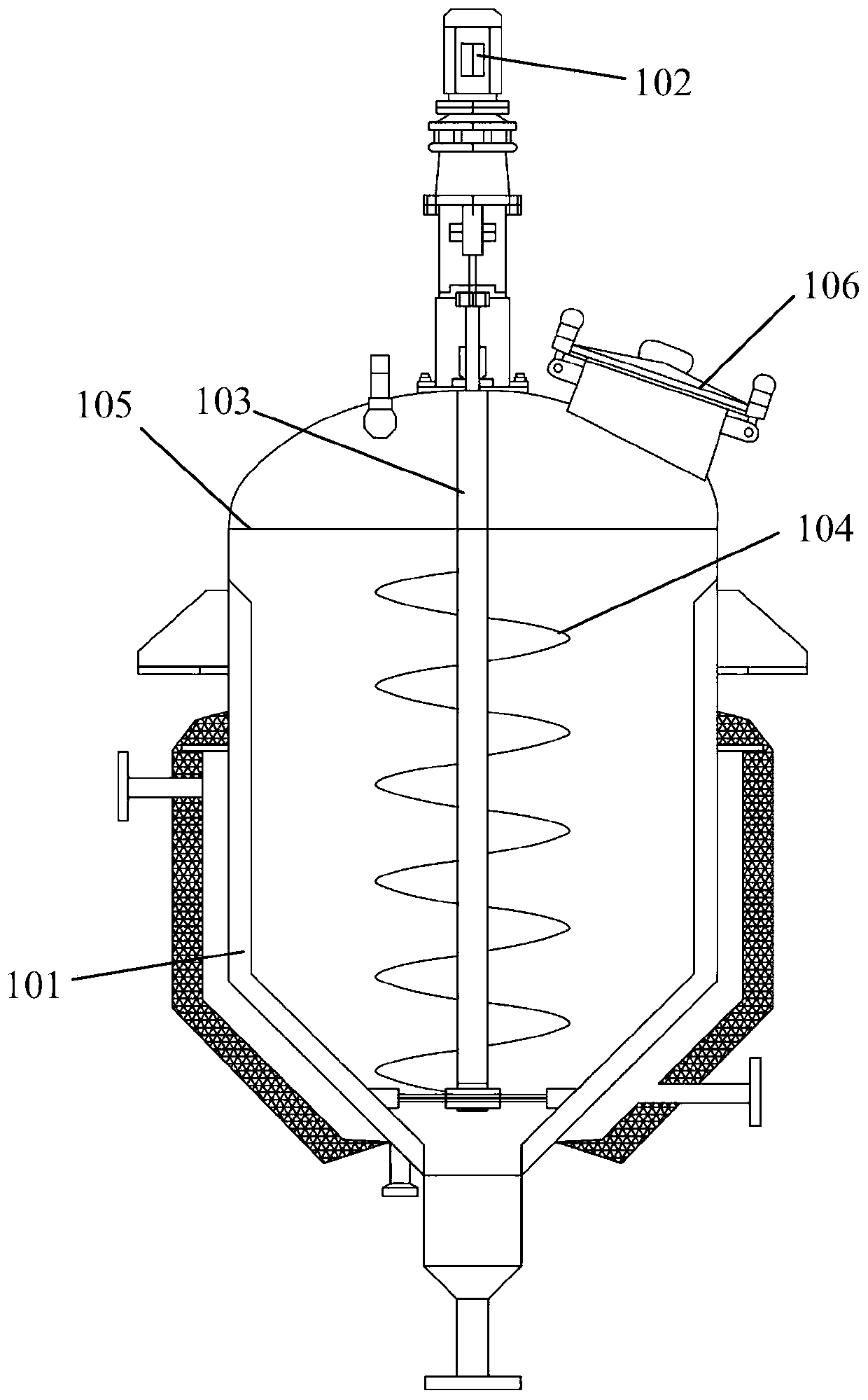

[0029] Please refer to the attached figure 1 , the present invention provides a heat reflux extraction and concentration equipment, comprising: an extraction tank 1, an evaporator 2, a heater 3, a condenser 4, a cooler 5 and an oil-water separator 6, wherein the liquid outlet of the extraction tank 1 is connected to the The liquid inlet of the evaporator 2 is connected, the gas outlet of the evaporator 2 is connected with the air inlet of the heater 3, the vapor return port of the extraction tank 1 and the inlet of the condenser 4 are connected with the gas outlet of the heater 3, and the condenser A cooler 5 is arranged between the outlet of 4 and the inlet of the oil-water separator 6, and the solvent outlet of the oil-water separator 6 is connected to the condensate return port of the extraction tank 1, and on the pipeline connecting the oil-water separator 6 and the extraction tank 1 A liquid inlet valve is provided.

[0030] In another embodiment, a filter 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com