Integral type spiral milling cutter wear image acquisition device and method based on machine vision

An image acquisition device, a technology of helical milling cutter, applied in milling machine equipment, details of milling machine equipment, metal processing mechanical parts, etc., can solve application and development limitations, turning tool image acquisition scheme is not suitable for integral helical milling cutter, image processing Increase the complexity and other problems to achieve the effect of solving the difficulty of image acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

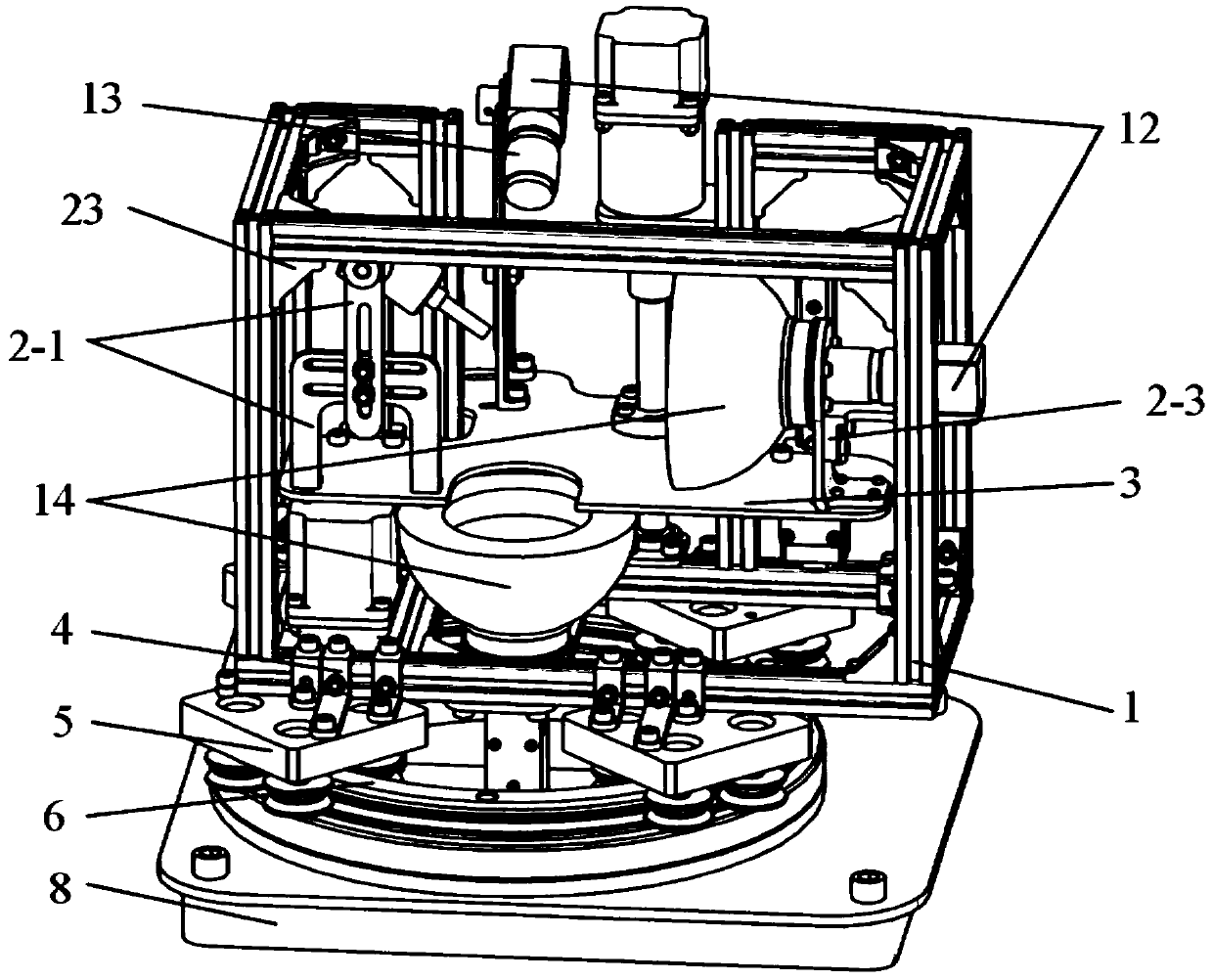

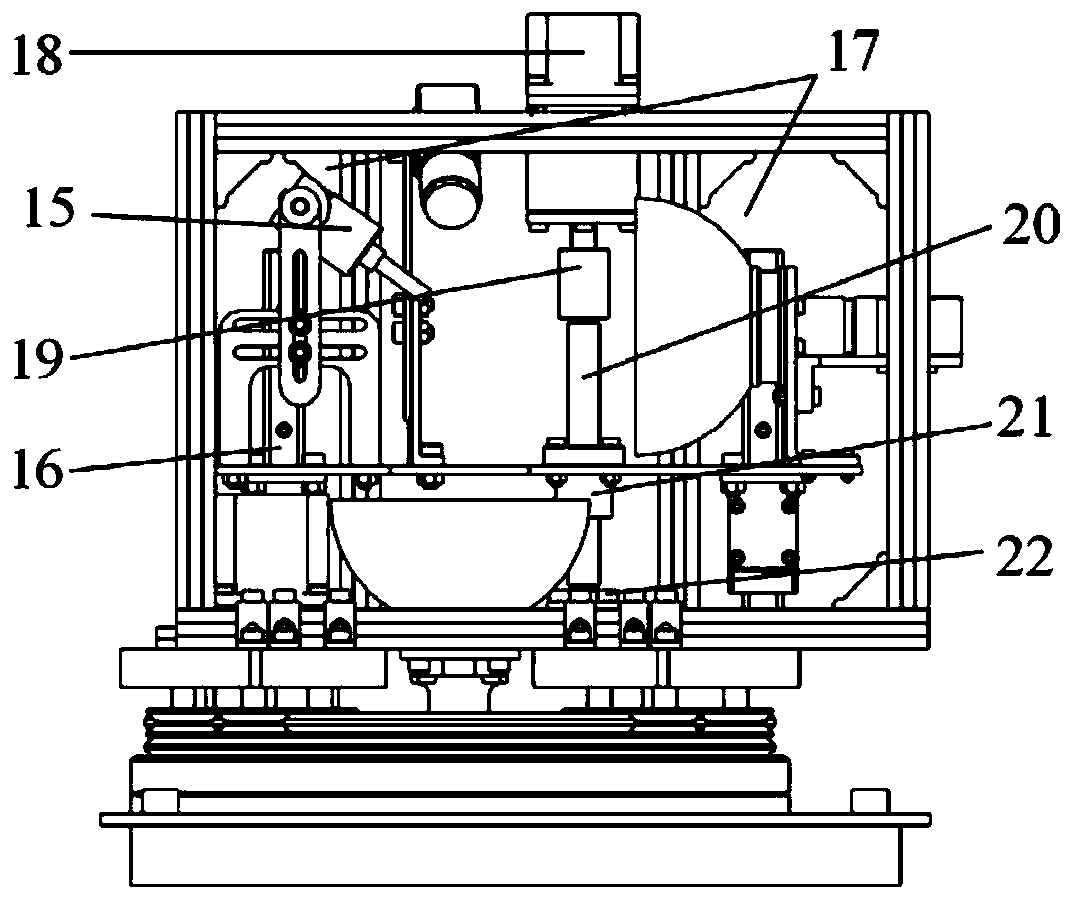

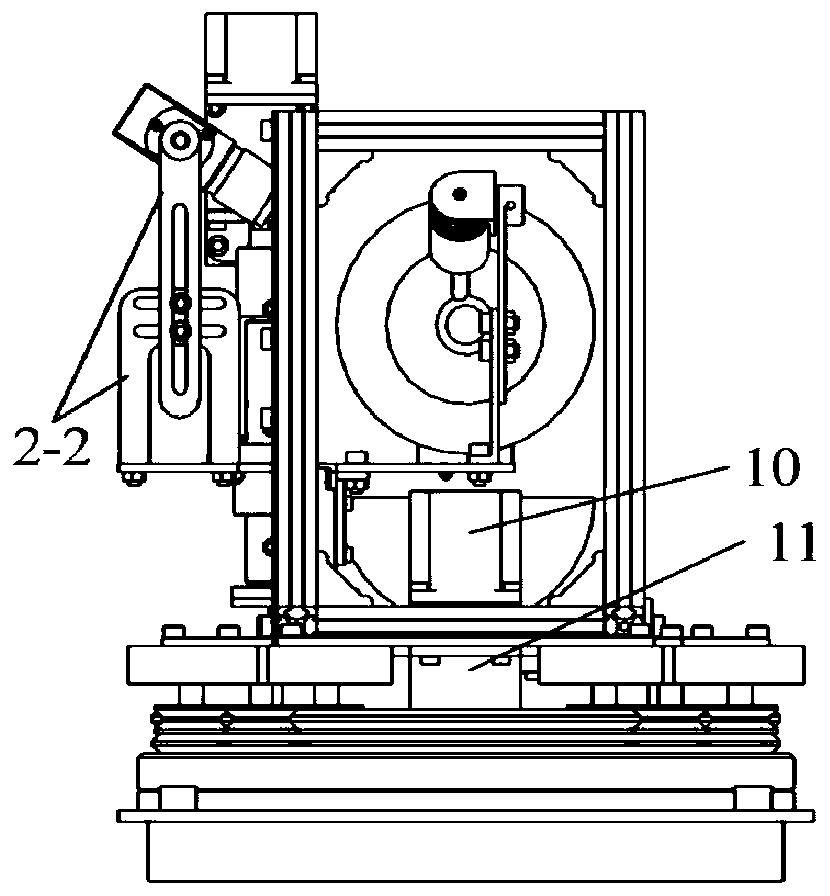

[0038]The machine vision-based integrated spiral milling cutter grinding damage image acquisition device of the present invention is mainly used for image acquisition of the spiral milling cutter grinding damage area widely used in the milling process, the tool is installed on the main shaft of the machine tool, and the image acquisition device is installed on the machine tool workbench a fixed location. It includes a camera, a light source and its fixed part, a linear moving device along the tool axis, and a circumferential rotating component with the tool axis as the rotation center. For each measurement, the tool is moved to the designated position, the images of each cutting part of the tool are collected by the camera, and transmitted to the computer for processing, storage and display. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com