Automatic production equipment of automobile injection molding parts

A technology for production equipment and injection molded parts, applied in the direction of coating, etc., can solve the problems of occupying a lot of space, injection molded parts cannot be stacked and stored, and the efficiency of automated production is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

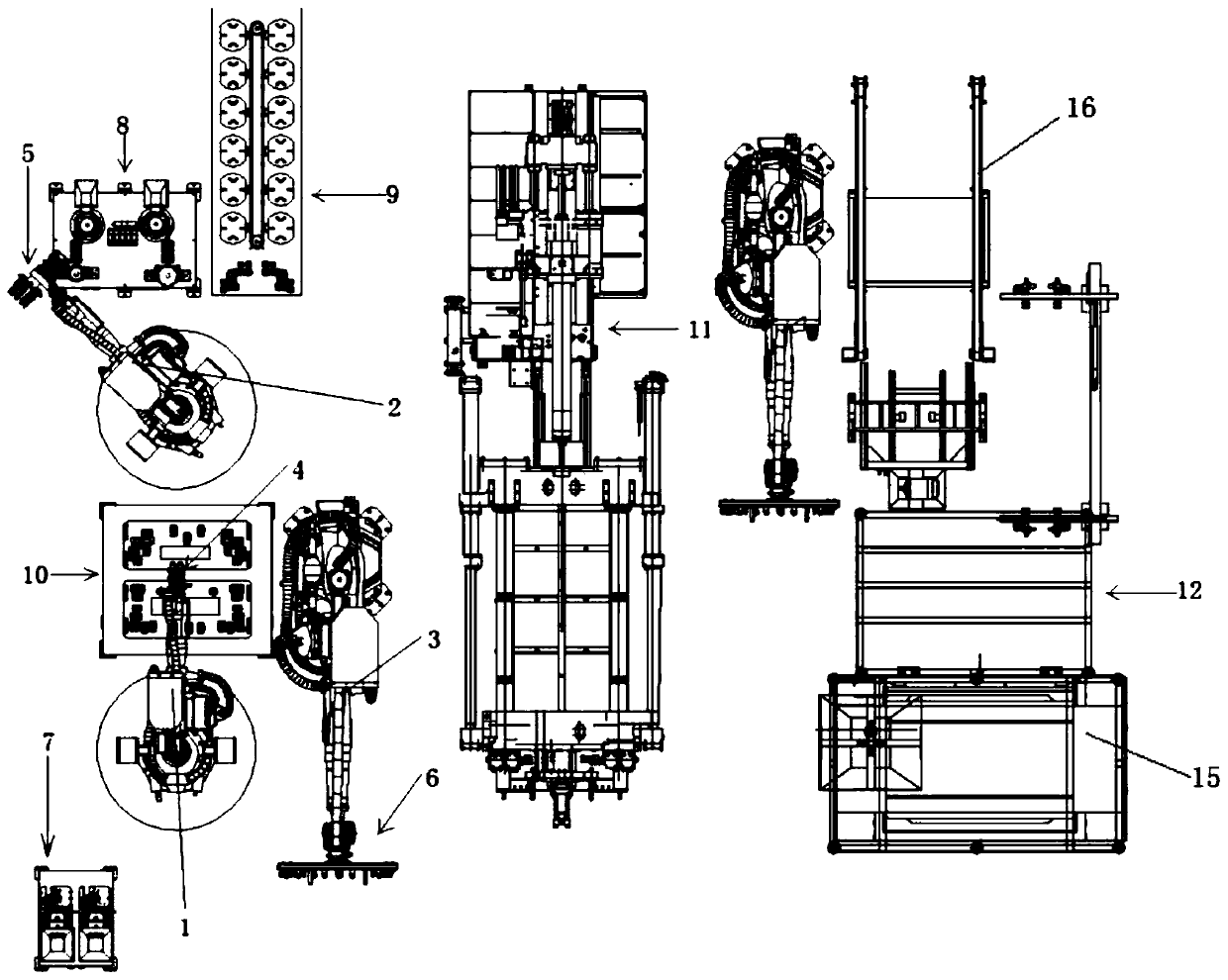

[0043] see Figure 1 to Figure 18 , The present invention relates to an automatic production equipment for automobile injection molded parts, including an insert installation mechanism, an injection molding machine 11, a post-processing equipment 12, a forklift 17, and a shelf 18.

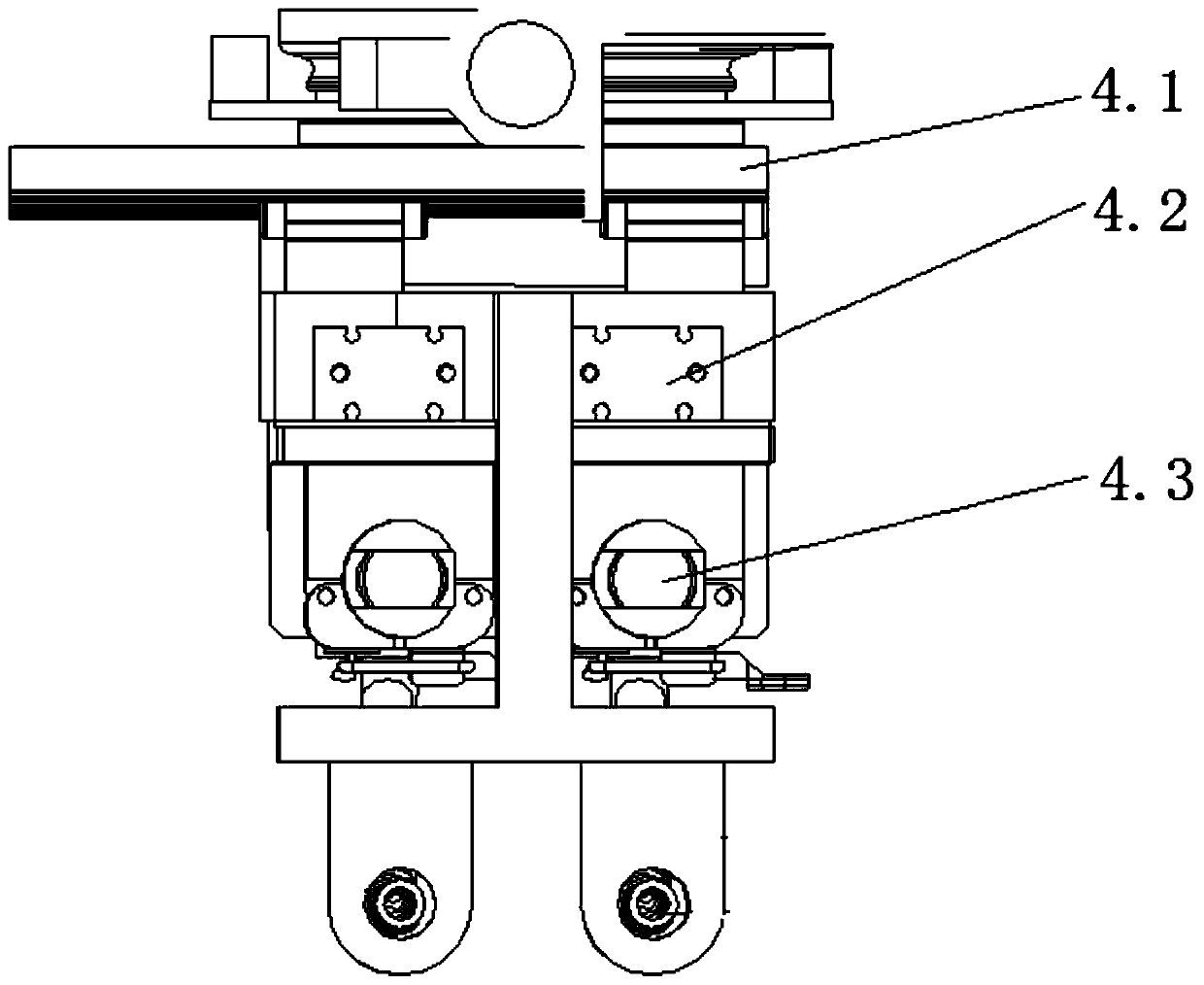

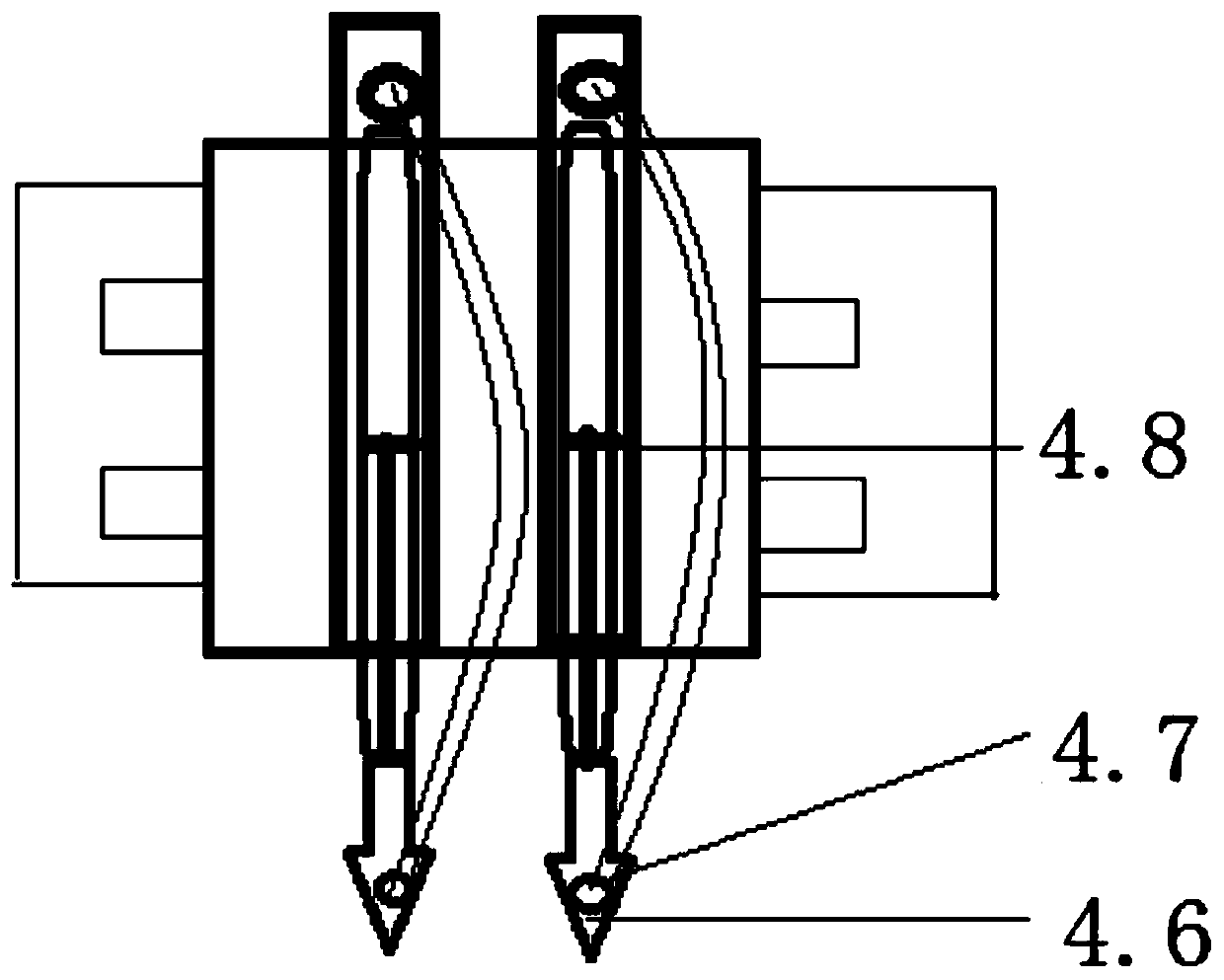

[0044] The insert installation mechanism includes No. 1 robot arm 1, No. 2 robot arm 2, No. 3 robot arm 3, nut insert auxiliary fixture 4, screw, positioning pin and sheet insert fixture 5, main insert fixture 6, nut Preset tooling 7, screw and positioning pin preset tooling 8, sheet insert preset tooling 9 and main insert preset tooling 10; nut insert sub-fixture 4 is connected to No. 1 mechanical arm 1, nut insert sub-fixture 4 Clamp the nut insert from the nut preset tooling 7 and place it on the main insert preset tooling 10. The No. 1 mechanical arm 1 can be made with the base as the center of the circle, and the length of the No. 1 mechanical arm 1 is 360% of the radius. Rotate ten degrees t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com