Control cabinet testing platform encoder single-phase single counting model

A test platform and encoder technology, applied in the field of elevators, can solve problems such as troublesome movement and handling of encoders and control cabinets, unstable operation of encoders, damage to electrical appliances such as encoders, etc., so as to avoid the appearance of cross-inductance and facilitate stable work , observe the intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

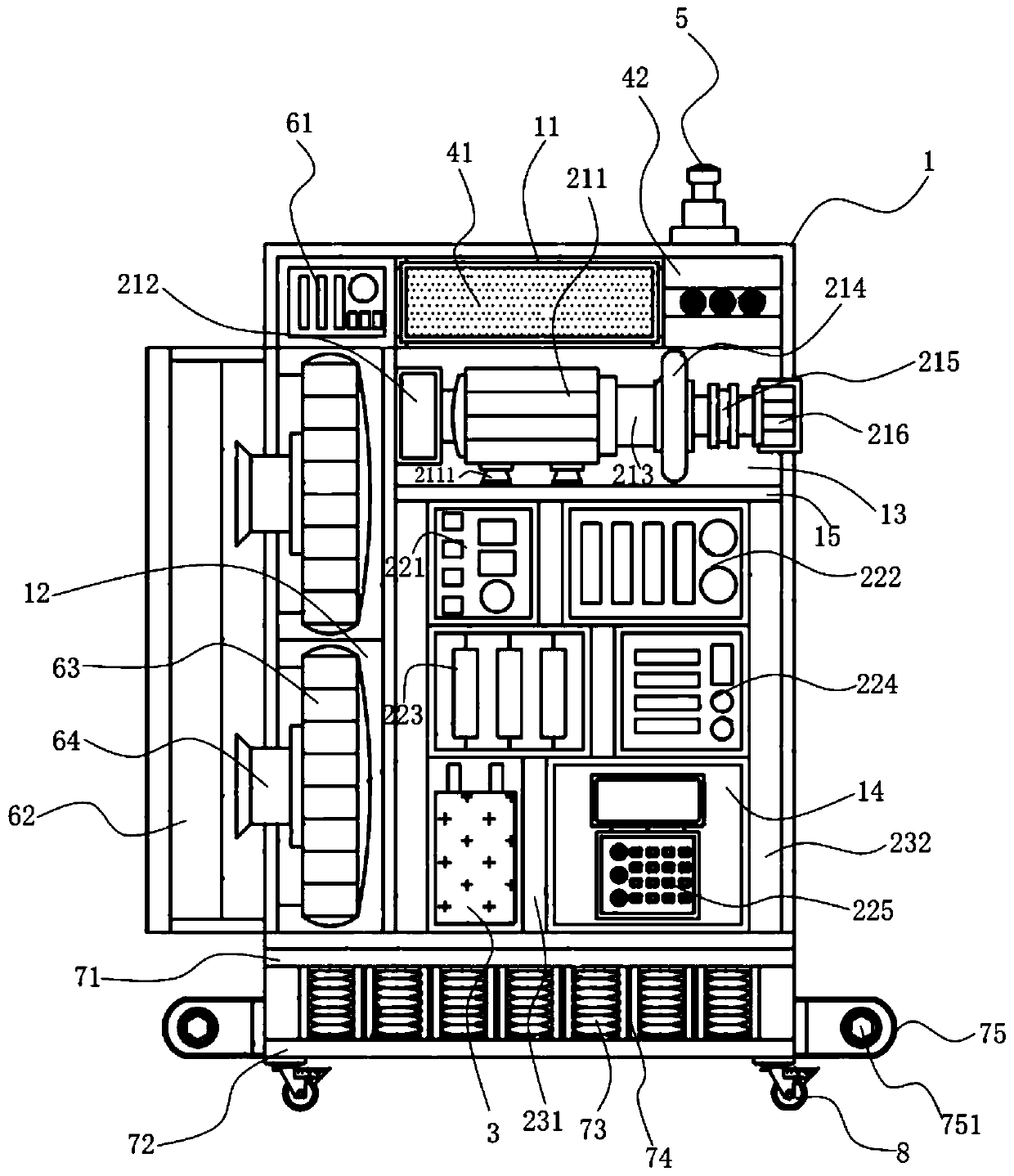

[0023] like figure 1 As shown, the present invention provides a single-phase single-counting model of a control cabinet test platform encoder, including a box body 1, a control unit, a backup power supply 3, a display unit, an alarm buzzer 5, a temperature control unit, a buffer unit and four Move wheel 8.

[0024] The box body 1 is hollow, and the interior is divided into a first installation area 11 , a second installation area 12 , a third installation area 13 and a fourth installation area 14 . The first installation area 11 is located at the top of the box 1, the second installation area 12 is located on the side below the first installation area 11, and the third installation area 13 and the fourth installation area 14 are located in the first installation area from top to bottom. The other side below zone 11.

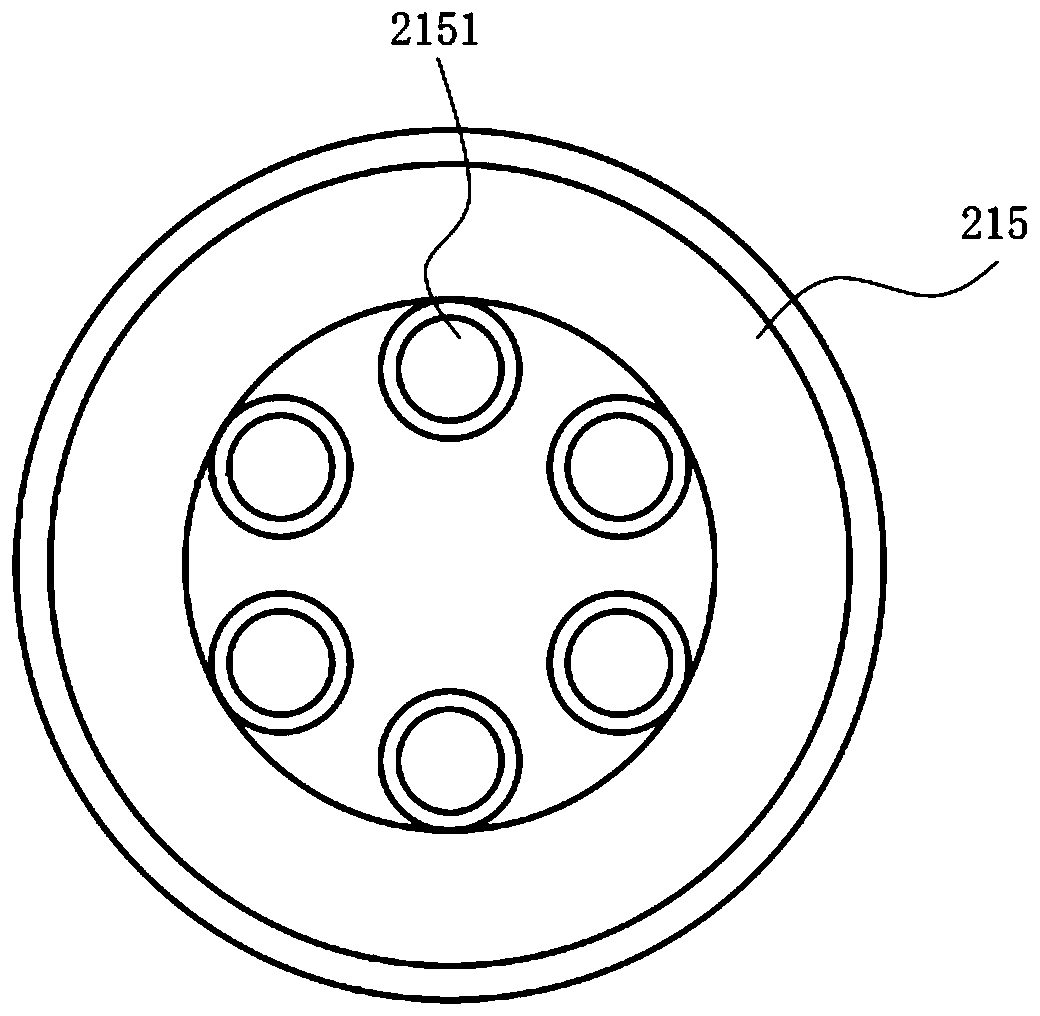

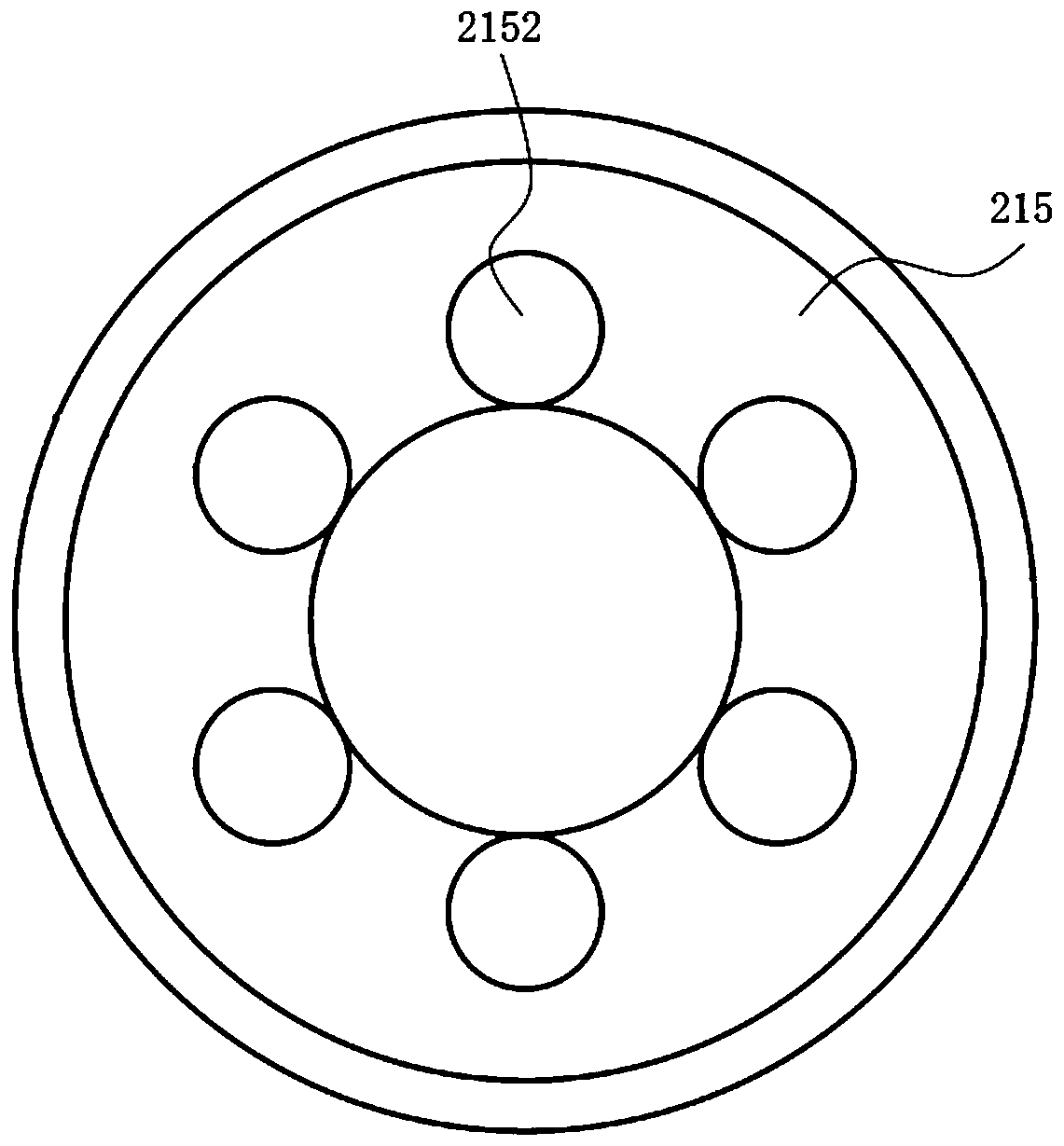

[0025] The control unit includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com