Steam heat pump sludge drying system

A sludge drying and heat pump technology, which is applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, chemical instruments and methods, etc., can solve the problems of restricted promotion, abundant steam, insufficient capacity of factory transformers, etc. problems, to achieve the effect of wide application range, small installed power, good economic value and promotion significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The present invention provides a steam heat pump sludge drying system in view of the fact that the existing electric heat pump sludge drying technology often faces the situation of insufficient transformer capacity and abundant steam in practical applications, which restricts its further promotion.

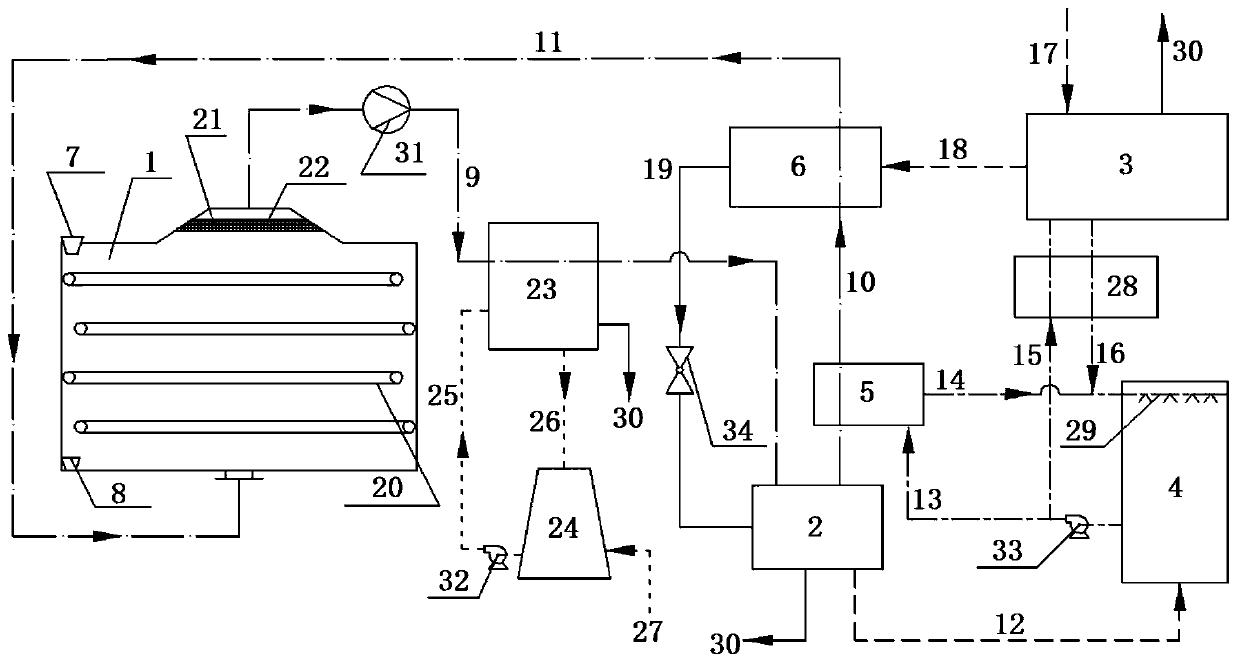

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a steam heat pump sludge drying system, including a sludge oven 1, an evaporator 2, a generator 3, an absorption tower 4, a preheater 5 and a condenser device 6; the sludge oven 1 is provided with a wet mud inlet 7 and a dry mud outlet 8, the top of the sludge oven 1 communicates with the evaporator 2 through a first air pipe 9, the The evaporator 2 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com