Electronic cigarette component antibacterial and anti-mildew material preparation method

A technology of antibacterial and antifungal parts, applied in the field of preparation of antibacterial and antifungal materials for electronic cigarette parts, which can solve problems such as bacterial residues, troublesome cleaning or replacement, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

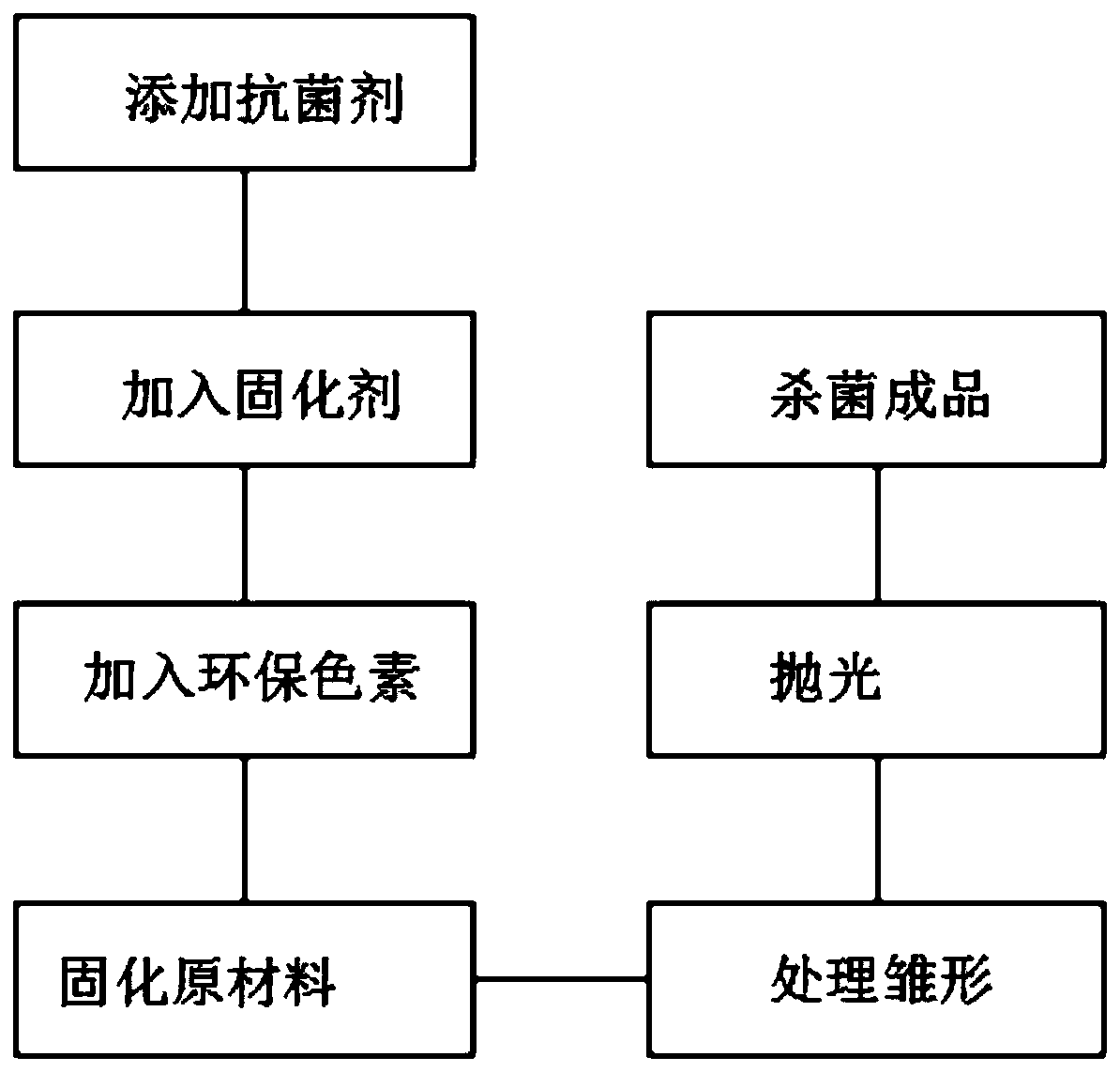

[0026] Please refer to figure 1 and figure 2 , the present invention provides a technical solution: a method for preparing an antibacterial and mildew-proof material for electronic cigarette parts, comprising the following steps:

[0027] S1: Add antibacterial agent, add the antibacterial agent to the epoxy resin raw material and mix evenly, let it stand for 1 hour, after the antibacterial agent is mixed with the epoxy resin raw material, the proportion of antibacterial agent is 1-3%;

[0028] S2: Add curing agent, stir the mixture in S1 with a mixer for 30 minutes, then add epoxy resin A and epoxy resin B curing agent, then add cosmetic No. 15 white oil dispersant, after standing for 45 minutes, the curing agent is One or more of ethylene polyamine, m-phenylenediamine and amidoamine, the curing temperature of polyethylene polyamine, m-phenylenediamine and amidoamine is 35-55 degrees Celsius;

[0029] S3: Add environmentally friendly pigments, then use a mixer to stir for 3...

Embodiment 2

[0036] Please refer to figure 1 and image 3 , the present invention provides a technical solution: a method for preparing an antibacterial and mildew-proof material for electronic cigarette parts, comprising the following steps:

[0037] S1: Add an antibacterial agent, add the antibacterial agent to the epoxy resin raw material and mix evenly, let it stand for 1 hour, after the antibacterial agent is mixed with the epoxy resin raw material, the proportion of the antibacterial agent is 1-3%;

[0038] S2: Add curing agent, stir the mixture in S1 with a mixer for 30 minutes, then add epoxy resin A and epoxy resin B curing agent, then add cosmetic No. 15 white oil dispersant, after standing for 45 minutes, the curing agent is One or more of ethylene polyamine, m-phenylenediamine and amidoamine, the curing temperature of polyethylene polyamine, m-phenylenediamine and amidoamine is 35-55 degrees Celsius;

[0039] S3: Add environmentally friendly pigments, then use a mixer to stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com