Efficient fabric homogenizing equipment

A fabric and high-efficiency technology, applied in the field of high-efficiency fabric homogenization equipment, can solve problems such as uneven homogenization, achieve the effect of ensuring uniformity and improving the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

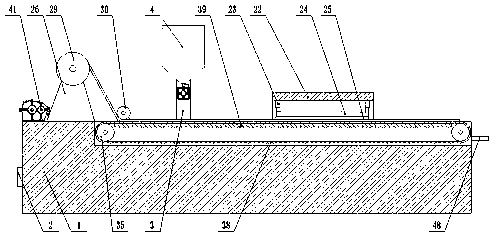

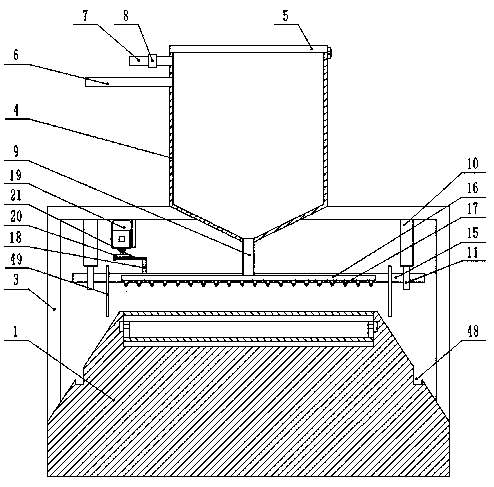

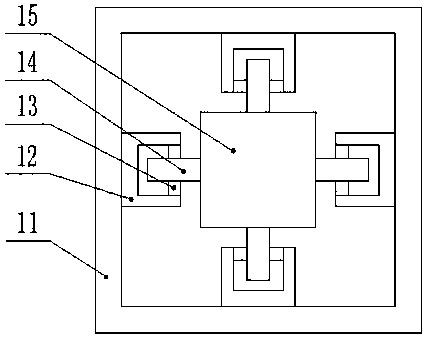

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7 As shown, in this implementation:

[0028] In this device, the device is powered by connecting with an external power supply, and the external power supply is electrically connected with the controller 2, the exhaust solenoid valve 8, the rotating motor 19, the electric telescopic rod 23 and the drive motor 40 for power supply, and the model of the controller 2 It is a PLC controller of the FBS-TC6 type, and the control signal output terminal of the controller 2 is electrically connected with the exhaust solenoid valve 8, the rotating motor 19, the electric telescopic rod 23 and the driving motor 40 respectively through the relay, so as to control the operation of the whole device .

[0029] The invention of this application lies in the structural design of the reciprocating rocking type spraying device, combined with the attached figure 1 , attached figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com