Device for preparing cellulose spinning slurry and preparation method thereof

A cellulose and slurry technology, applied in the field of slurry preparation equipment for NMMO dissolved cellulose spinning, can solve the problems of unfavorable spinning production, easy decomposition and discoloration of NMMO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

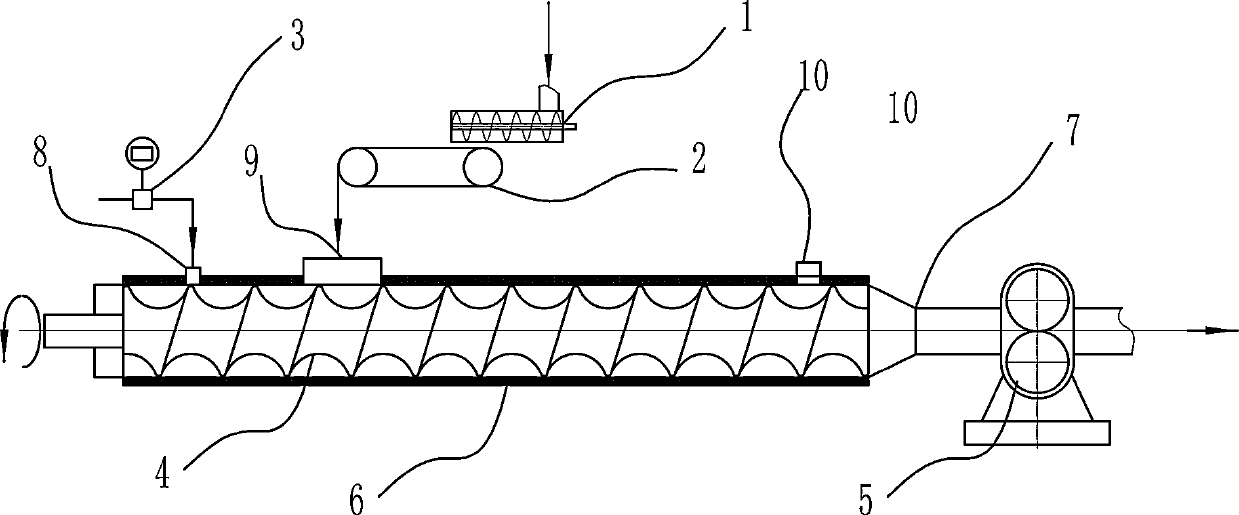

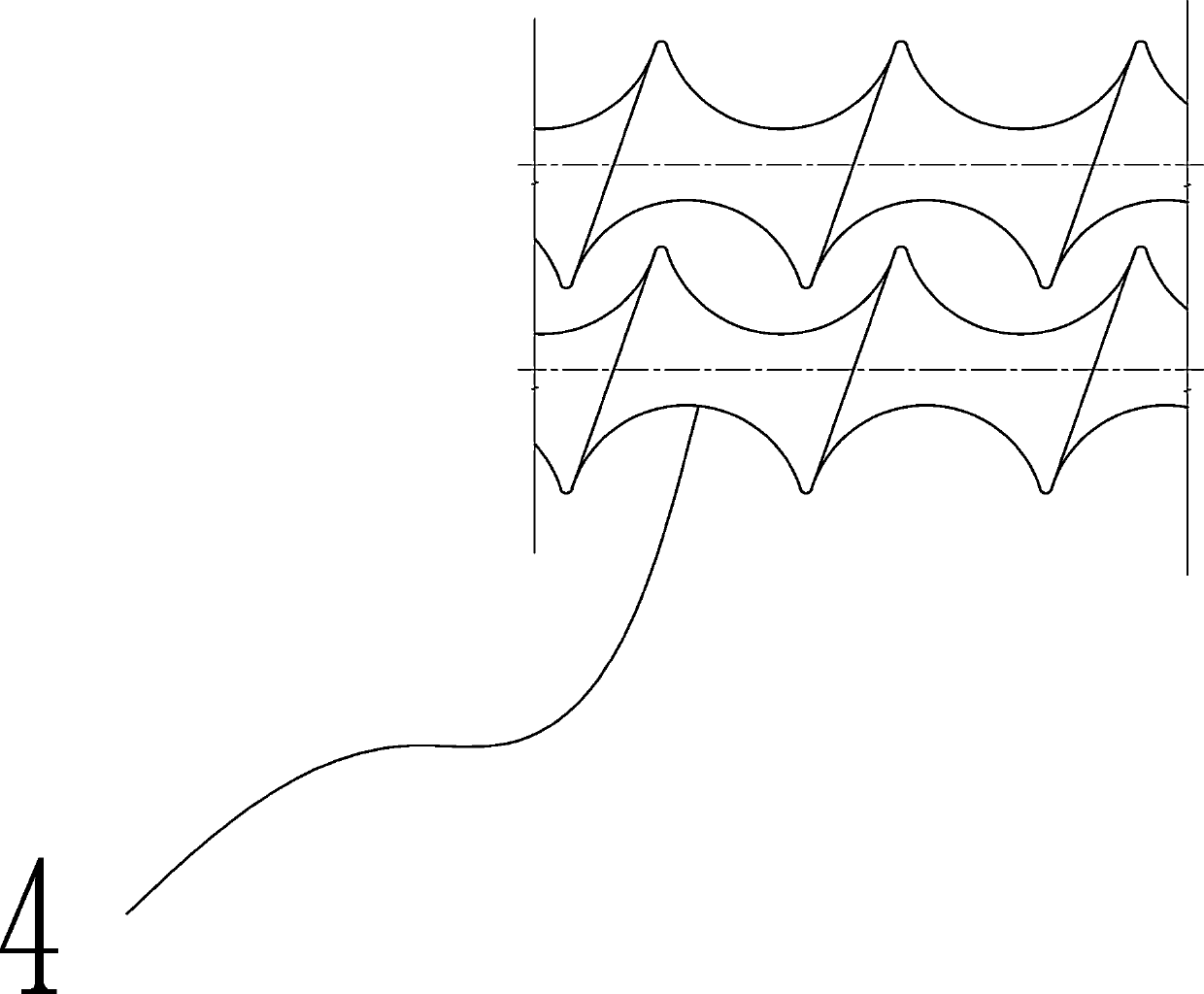

[0021] Such as Figure 1~2 As shown, a device for preparing cellulose spinning slurry includes a twin-screw extruder 4, a screw conveyor 1 and a gear pump 5, and one end of the twin-screw extruder 4 is provided with a feed inlet, and the feed inlet includes The first feed port 8 and the second feed port 9, the second feed port 9 communicates with the screw conveyor 1, the discharge port 7 at the other end of the twin-screw extruder 4 communicates with the gear pump 5, With this structure, the first feed port 8 is used to transport NMMO liquid, the second feed port 9 is used to transport pulp powder, the twin-screw extruder 4 adopts co-rotating conjugated twin-screws, and the co-rotating conjugated twin-screws reinforce Due to the constraints of the gear pump 5, the pressure of the slurry gradually increases when the slurry moves from the head to the tail in the 4 cavities of the twin-screw extruder, especially when the slurry is accelerated under the action of a large pressure...

Embodiment 2

[0028] Further illustrate in conjunction with embodiment 1, as Figure 1~2 As shown, the NMMO is prepared to be NMMO with a moisture content of less than 15%, and the heating jacket 6 on the outer wall of the twin-screw extruder 4 is heated to 85°~95°, so that the NMMO sent into the system is NMMO with a moisture content of less than 15% and a temperature greater than 85°C. NMMO meets the temperature conditions for slurry preparation, and solves the problem that NMMO is prone to decomposition and discoloration at high temperatures (greater than 85°C), and the higher the temperature, the more severe the decomposition and discoloration, which is unfavorable to spinning production.

[0029] After the NMMO is measured by the liquid flow meter 3, it is input into the twin-screw extruder 4, and the screw conveyor 1 will transport the pulp powder to the belt scale 2 for weighing, and after weighing, it is also input into the twin-screw extruder 4, NMMO and pulp The powder is mixed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com