Semi-prefabricated UHPC shell overlap cover beam and prefabricated pier stud connecting structure and construction method thereof

A semi-prefabricated and prefabricated pier technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting durability, discontinuity, and high support costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

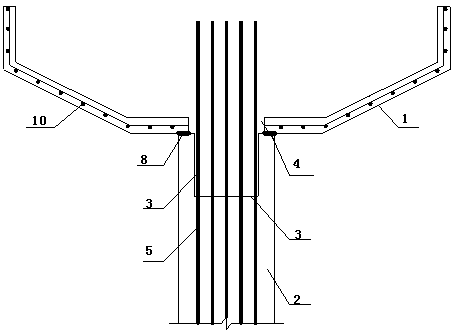

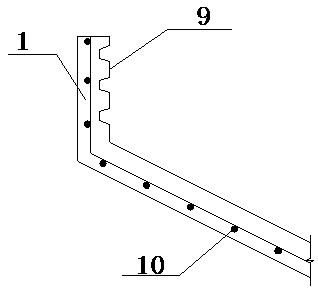

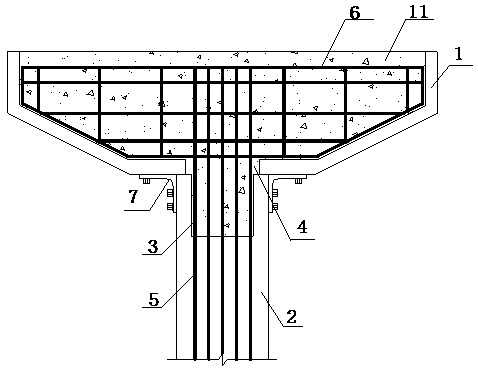

[0026] like Figure 1~4 As shown, a semi-prefabricated UHPC shell superimposed cover beam and prefabricated pier column connection structure, including a semi-prefabricated UHPC cover beam shell 1 and a prefabricated pier column 2 located under the semi-prefabricated UHPC cover beam shell, the semi-prefabricated UHPC cover The beam shell is a shell-shaped structure with an inner hollow and no cover. The top of the prefabricated pier column is vertically provided with a pier column rear sprue 3, and the bottom of the semi-prefabricated UHPC cover beam shell is provided with a pier column. The coaxial and matching through-hole 4 of the rear pouring groove is located at the center of the bottom of the semi-prefabricated UHPC cover beam shell, and several pier colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com