Fabricated anti-seismic bridge pier

A prefabricated and pier technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of low bearing capacity, insufficient shear force and stability, etc., and achieve large shear bearing capacity, good seismic effect and long service life high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

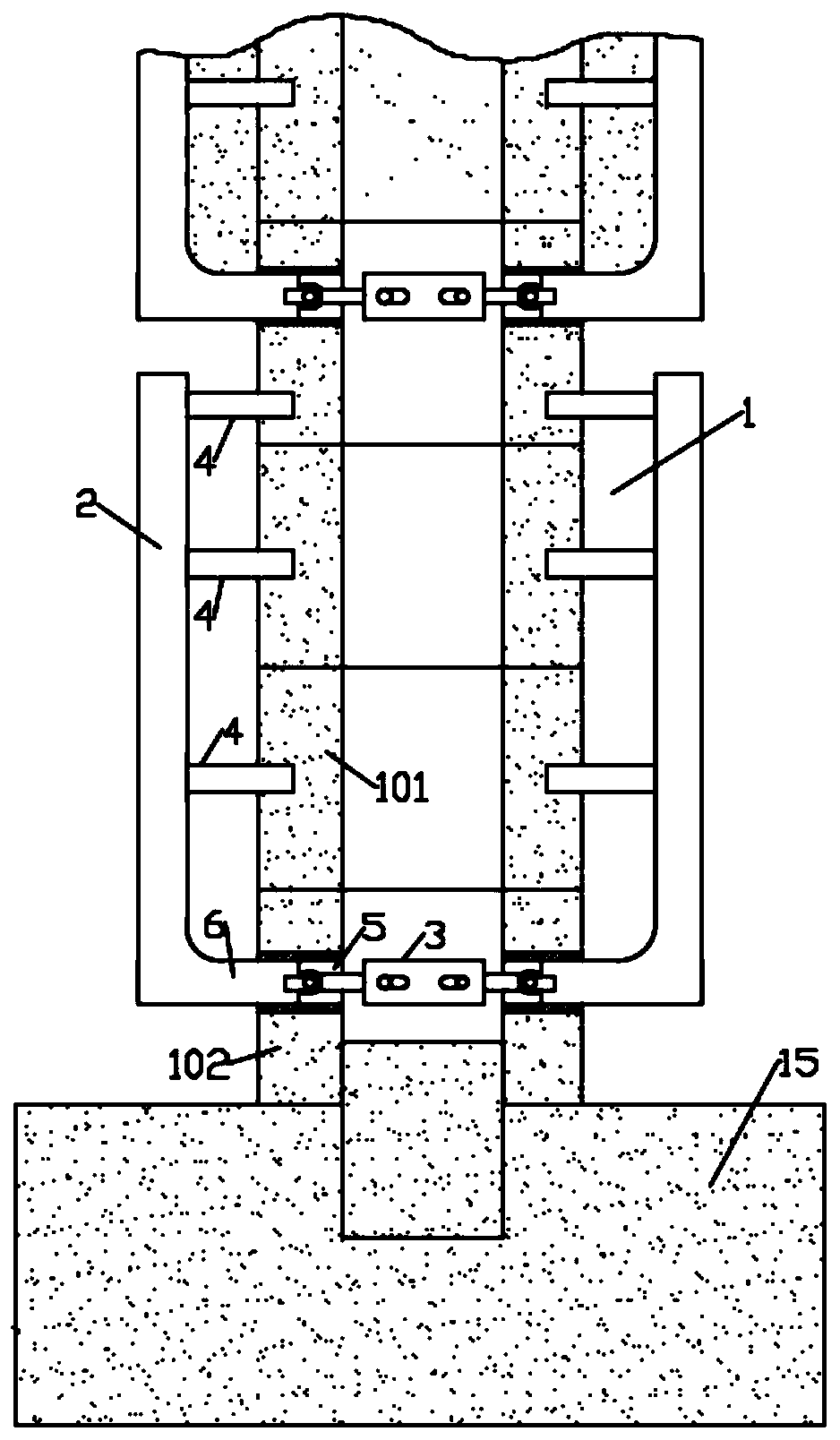

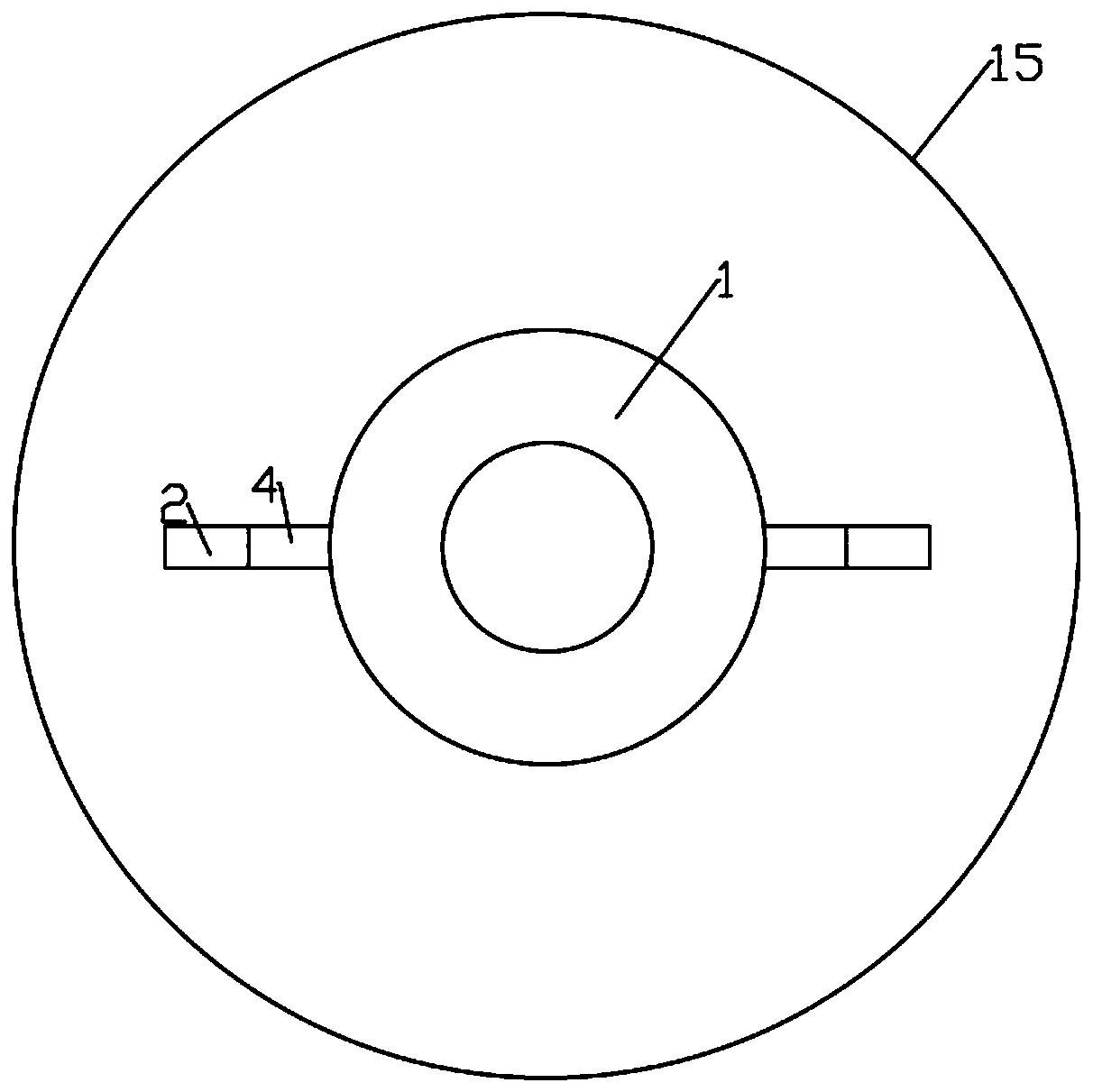

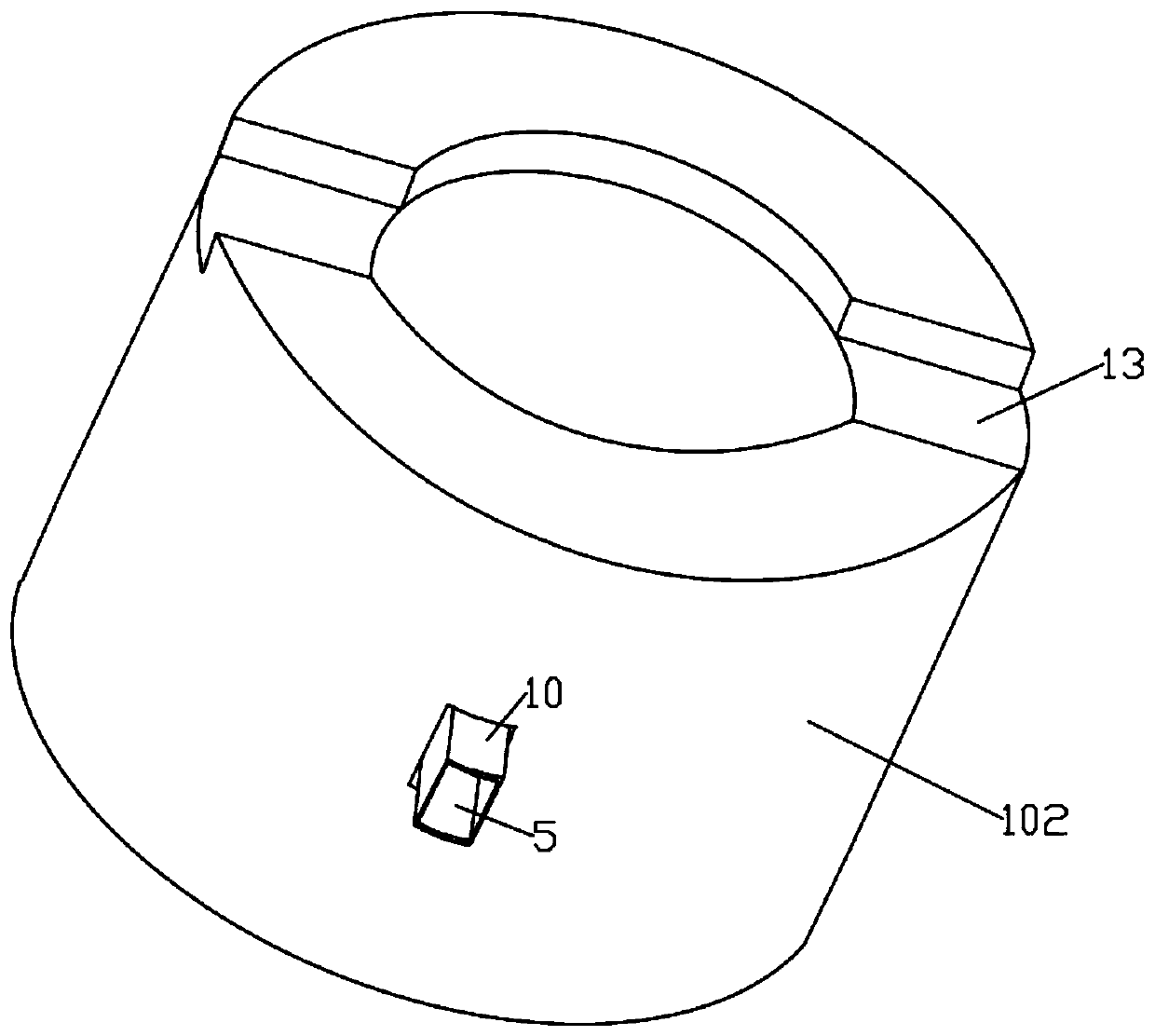

[0025] figure 1 It is a structural schematic diagram of the invention, figure 2 for figure 1 top view of image 3 is a schematic diagram of the layout of the chute, Figure 4 is a schematic diagram of the raised arrangement, Figure 5 Schematic diagram of the structure of the shock absorbing beam, Figure 6 A schematic diagram of the structure of the damper, Figure 7 It is a structural schematic diagram of another embodiment of the present invention. An assembled anti-seismic bridge pier according to the present invention includes a pier body 1 formed by sequentially assembling several segments from bottom to top, at least one vertical shock-absorbing beam 2 is arranged on the side of the pier body 1, and the shock-absorbing beam 2 and the pier body 1 is provided with a damper 3, and the shock-absorbing beam 2 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com