Open-hole thin steel plate and ultra-high-performance concrete composite structure and construction method thereof

An ultra-high performance, combined structure technology, applied in building components, building structures, building materials, etc., can solve problems such as weakening mechanical properties, and achieve the effects of increasing mechanical properties, improving crack resistance, and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

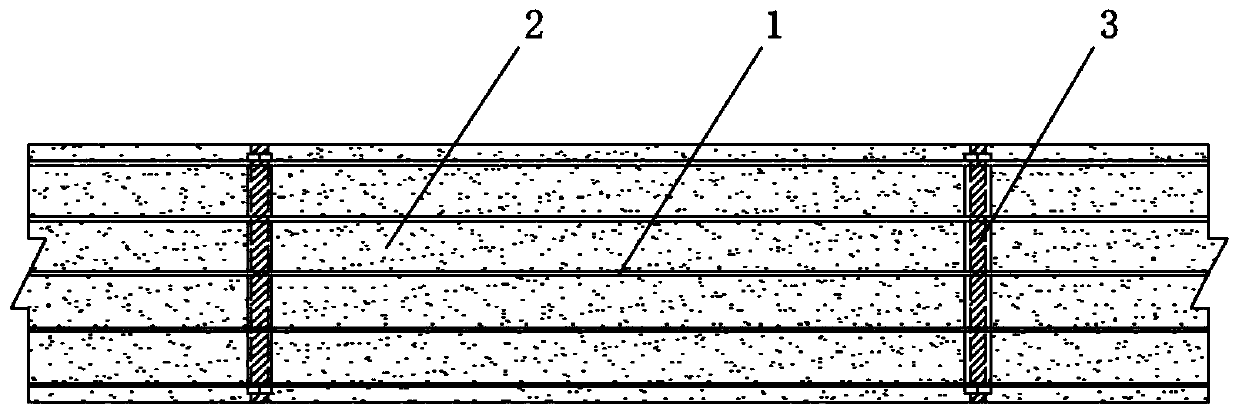

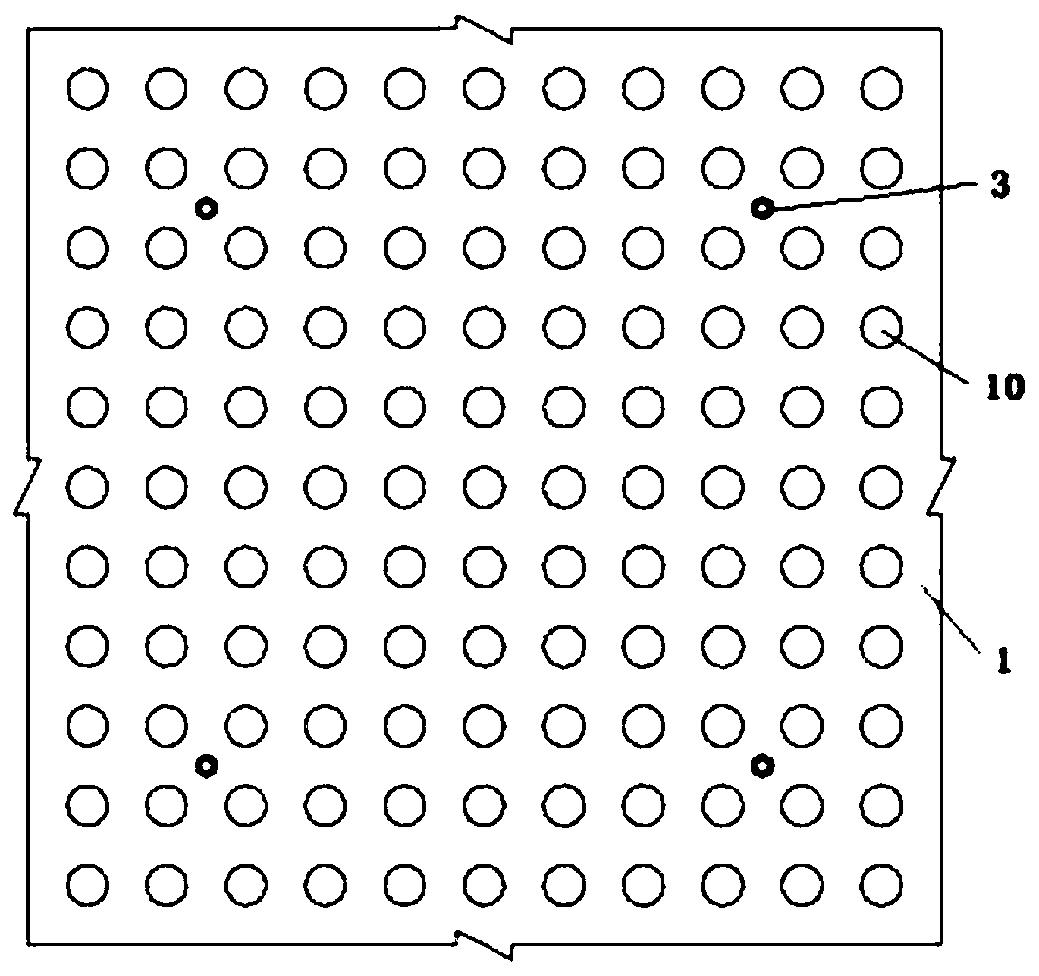

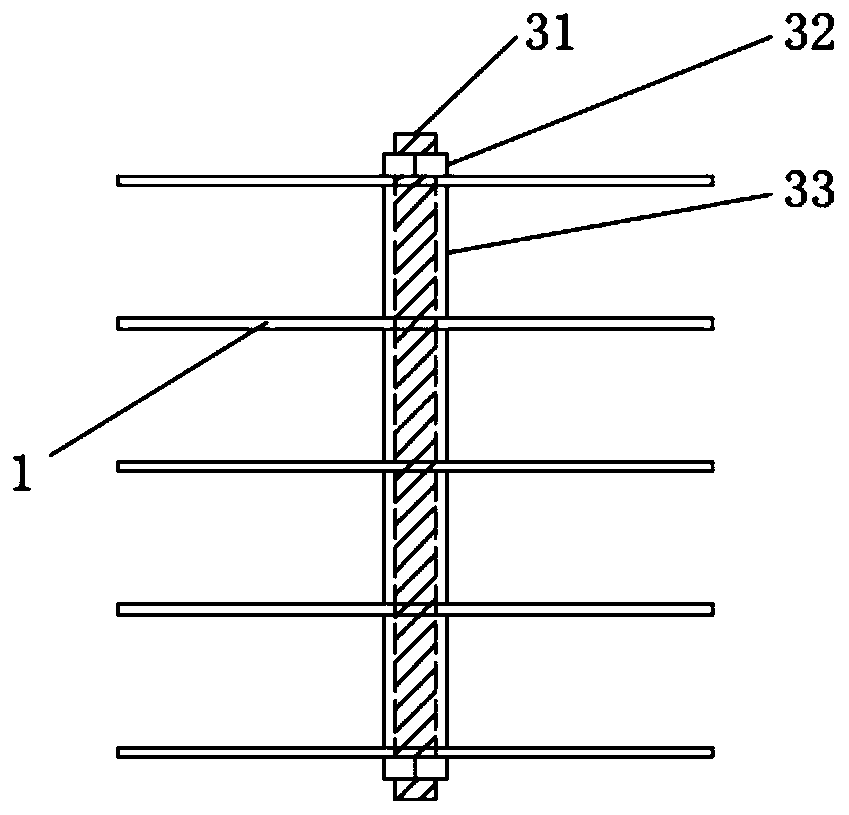

[0039] see figure 1 As shown, the embodiment of the present invention provides an open-hole thin steel plate-ultra-high performance concrete composite structure, the composite structure includes: a plurality of thin steel plates 1 distributed at intervals, all the thin steel plates 1 form a filling space, and the The height of the filling space is equal to the distance between the two outermost thin steel plates 1, and the projection plane of the filling space is equal to the union of the orthographic projection planes of all the thin steel plates 1; The small hole 10 for filling the space; at least three limiters 3 arranged in parallel, each of the limiters 3 is pierced on all the thin steel plates 1, and the three limiters 3 are in The projections on the same thin steel plate 1 are not collinear; in the embodiment of the present invention, the number of the limiting parts 3 is four; ultra-high performance concrete 2 is filled in the filling space.

[0040] The perforated th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com