Weak grating based single-component and three-component fiber grating vibration sensors and three-component fiber grating vibration sensing array

A technology of vibration sensor and optical fiber grating, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult to realize large-scale sensing unit networking, three-component optical fiber vibration sensor lateral cross-sensitivity, etc., to achieve lateral sensitivity reduction, The effect of high positioning accuracy and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

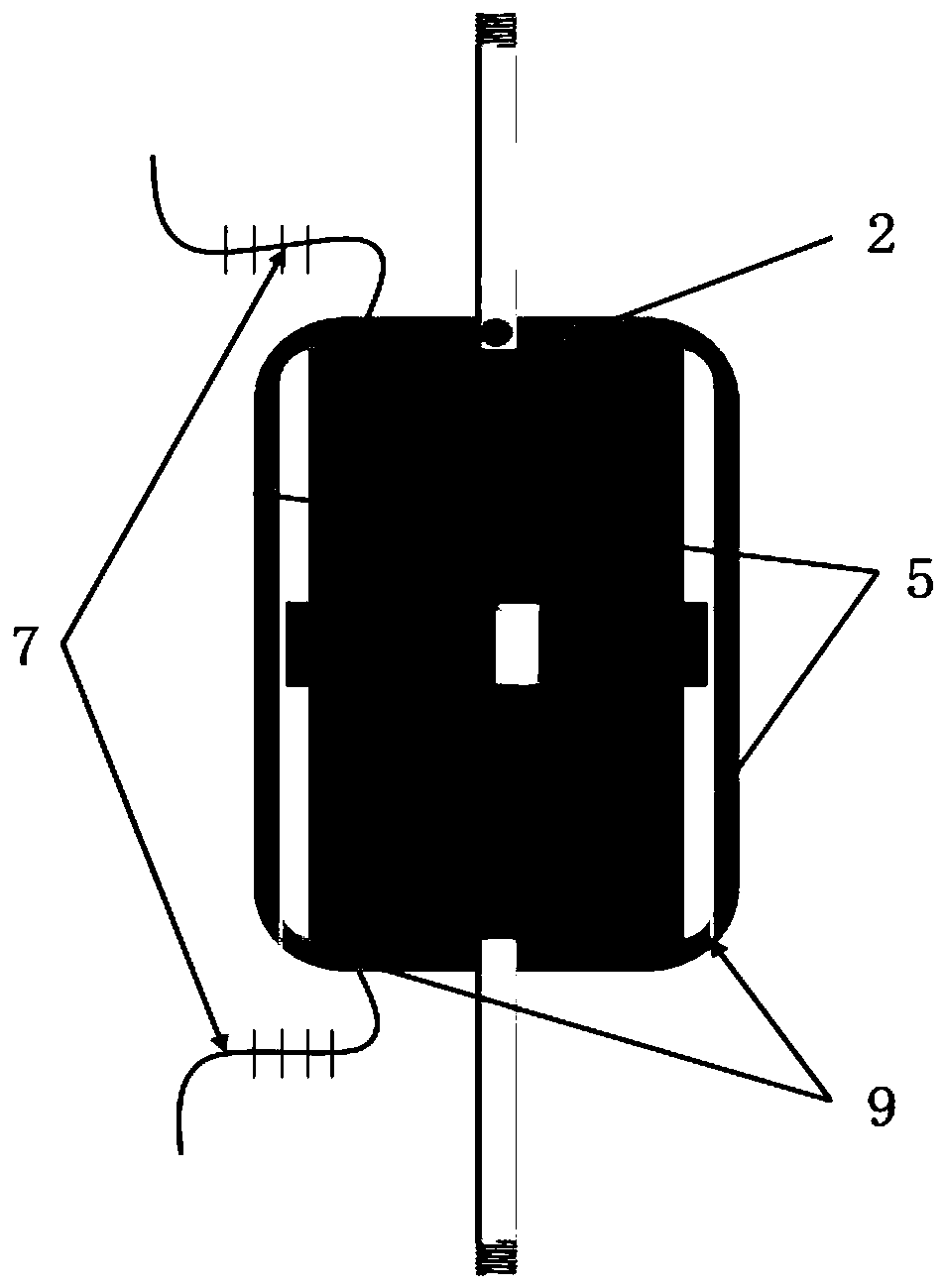

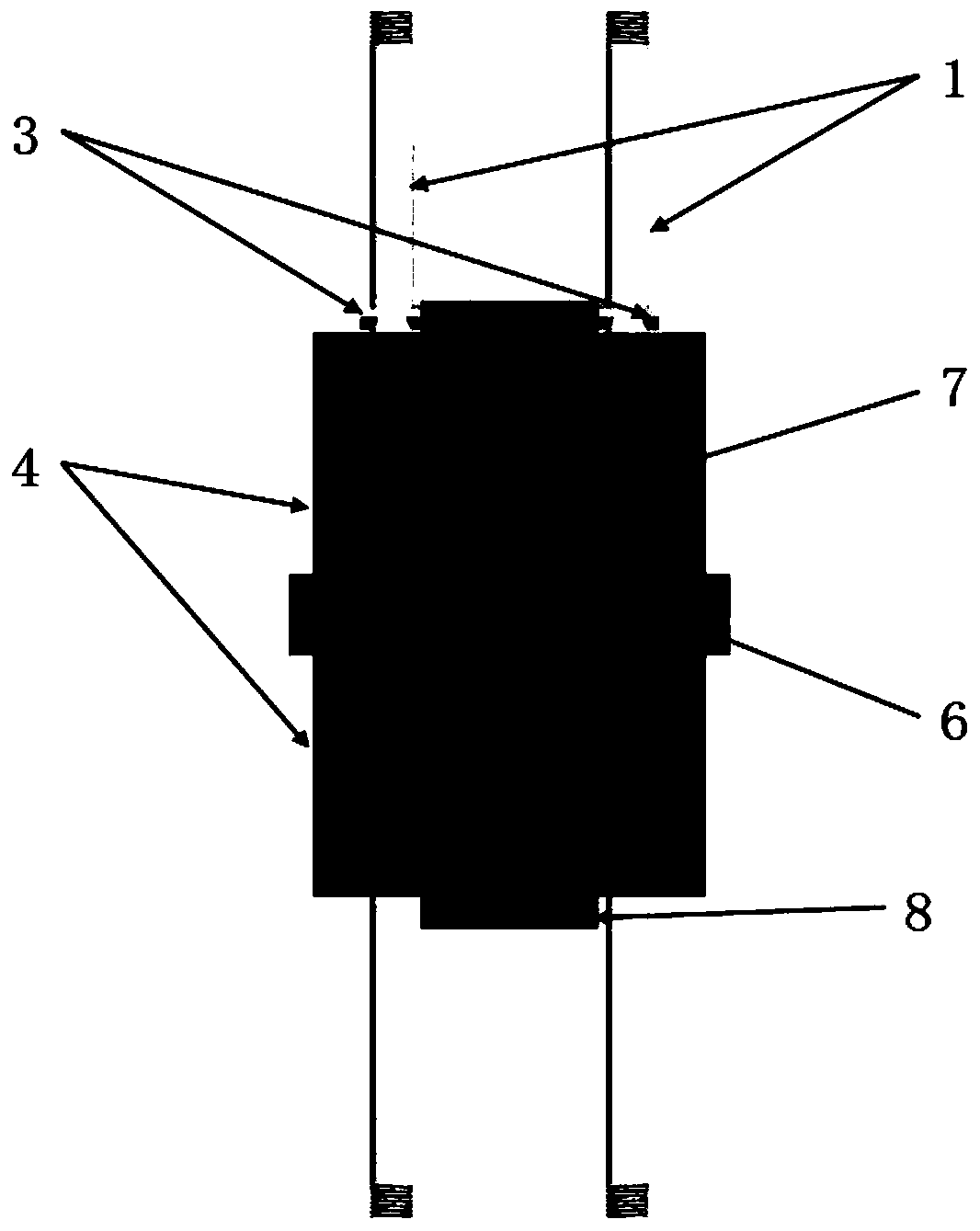

[0029] Specific implementation mode 1: refer to figure 1 and figure 2 As shown, the single-component fiber grating vibration sensor specifically includes: a rigid beam 1, a fixed end 2, a set screw 3, a hollow elastic cylinder 4, a connecting frame 5, a mass block 6, a fiber grating 7, a movable end 8 and a miniature slide Block 9.

[0030] In the single-component fiber grating detector of this embodiment, the material of the hollow elastic cylinder 4 used is silicon rubber, and the specifications of the upper and lower hollow elastic cylinders are exactly the same, and they are symmetrically arranged on both sides of the mass block 6, and the mass block is made of ordinary metal material. The shape is processed into a cylinder, which saves space and facilitates installation. The elastic cylinder 4 and the mass block 6 are fixed with superglue to form an inertial element, and then the upper end and the fixed end 2 of the composed inertial element are fixed with superglue, a...

specific Embodiment approach 2

[0032] Specific implementation mode 2, this implementation mode is a further description of the single-component detector based on the specific implementation mode 1. Such as figure 1 , figure 2 As shown, the rigid beam, the fixed end, the movable end and the micro-slider are all processed from a material with better rigidity, and the surfaces of the fixed end, the movable end and the micro-slider are flat, and they are used as two inertial components. The elastic tube has the same specification and shape, the end face is flat, and the surface of the mass block is smooth and smooth. The surfaces of the elastic cylinder, the mass block, the fixed end and the movable end are fixed with superglue, and the surfaces are pasted flat without gaps, and are always kept parallel to each other.

specific Embodiment approach 3

[0033] Specific implementation mode 3, this implementation mode is further described on the specific implementation mode 2. Rigid beams are always perpendicular to the surfaces of the elastic tube, mass, and peripheral frame as they pass through the structure. The set screw fixes the fixed end and the rigid beam together, and the relative displacement between the fixed end and the rigid beam is always zero.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com