A foam cable, injection mold, foam extruder and production process

A technology of injection mold and extruder, which is applied in the field of injection mold, foam extruder and production process, and foamed cable, can solve problems such as affecting the bending performance of cables, and achieve the effect of enhancing bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

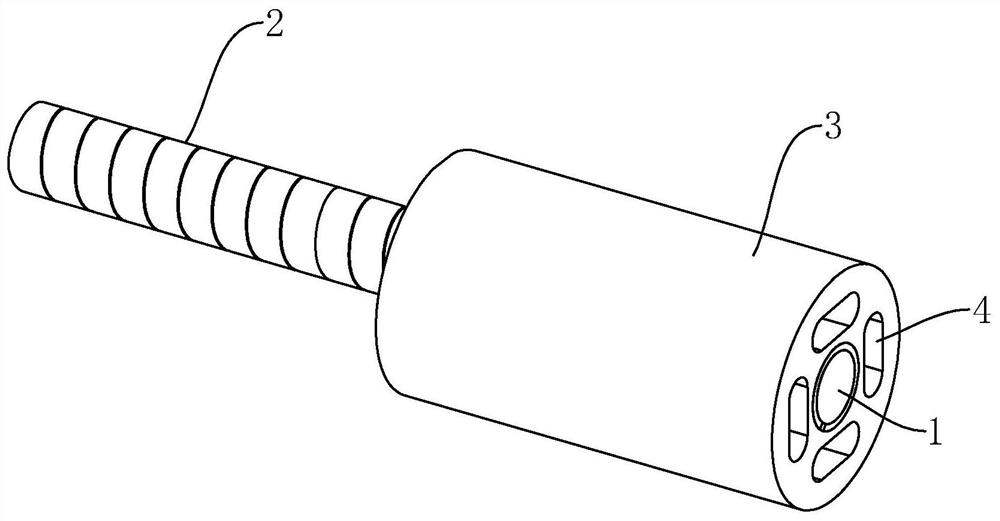

[0052] like figure 1 As shown, a foamed cable includes a conductive wire core 1 , a mica tape 2 coated on the outer side of the conductive wire core 1 , and a foamed insulating layer 3 coated on the outer side of the mica tape 2 .

[0053] like figure 1 As shown, the mica tape 2 is wrapped on the outer side of the conductive wire core 1 in a spiral structure, and the edge of the mica tape 2 covered after is covered on the mica tape 2 wrapped in the previous circle to form a dense fire-resistant insulating structure.

[0054] like figure 1 As shown, the foamed insulating layer 3 is made of foamed PE, and the inside of the foamed insulating layer 3 is formed with four inner holes 4 along the length direction of the cable. Observed from the cable section, the cross-section of the inner holes 4 is elliptical and along the length of the cable. The conductive wire cores 1 are evenly distributed in the circumferential direction. The inner hole 4 saves the material used for foaming...

Embodiment 2

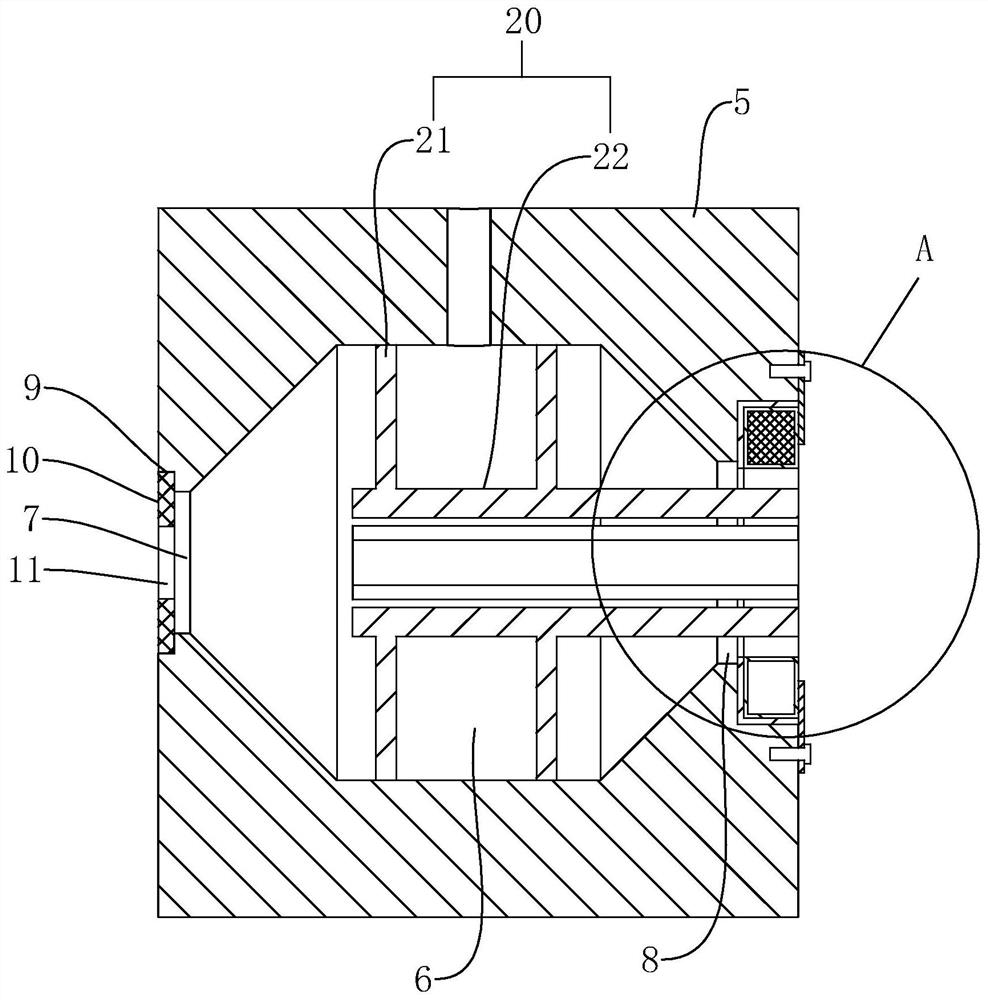

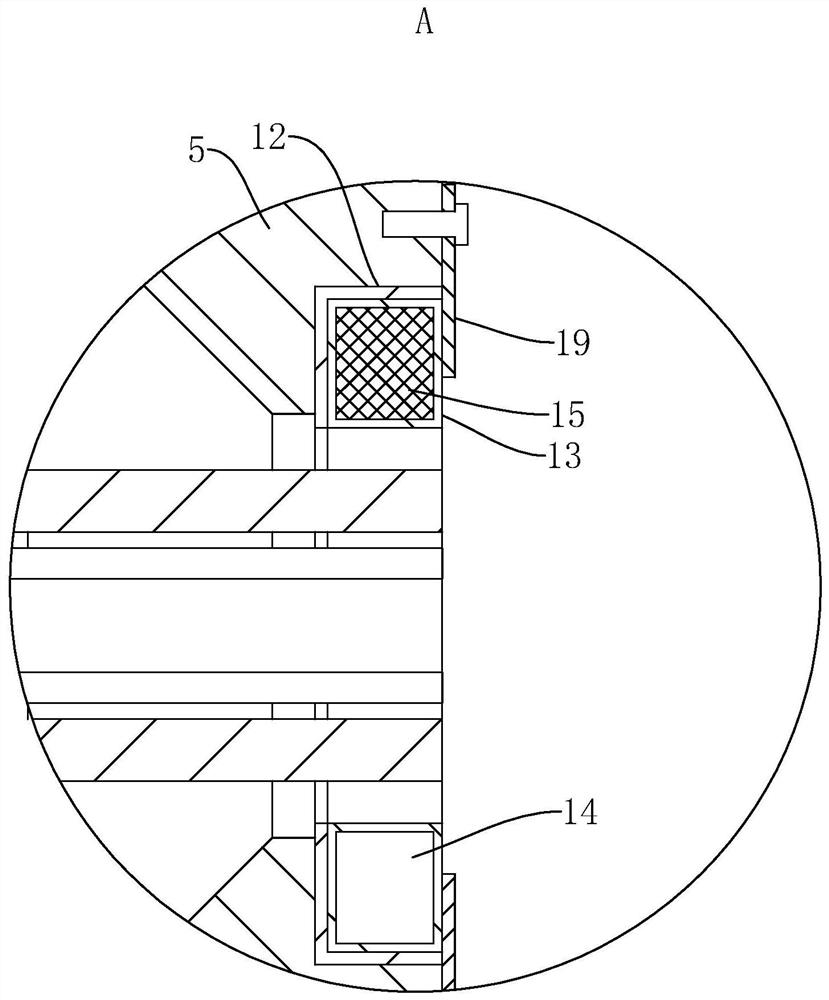

[0056] like figure 2As shown, an injection mold for the foamed cable described in the first embodiment includes a mold body 5, and an extrusion cavity 6 is formed inside the mold body 5, and the two ends of the extrusion cavity 6 penetrate through to form a cavity inlet 7 and the outlet port 8. The side surface of the mold body 5 is formed with a feed port that communicates with the extrusion cavity 6 , and the foaming injection molding machine transports the foamed PE into the extrusion cavity 6 . The conductive wire core 1 enters the extrusion cavity 6 through the cavity inlet 7 , the conductive wire core 1 enters the extrusion cavity 6 and then the foamed PE wraps the outer side of the conductive wire core 1 , and then is transported out from the cavity outlet 8 .

[0057] like figure 2 As shown, the end face of the mold body 5 with the cavity inlet 7 is formed with a sealing groove 9, and a sealing ring 10 is embedded in the sealing groove 9. The center of the sealing...

Embodiment 3

[0062] A foaming extruder includes an extruder body and the injection mold described in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com