Single battery, power battery pack and vehicle

A single battery and casing technology, which is applied in the field of vehicles, can solve the problems affecting the high-current charging and discharging performance of power batteries, safety performance, long current collection path, and large battery size, so as to achieve better versatility and improve overcurrent , the effect of reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

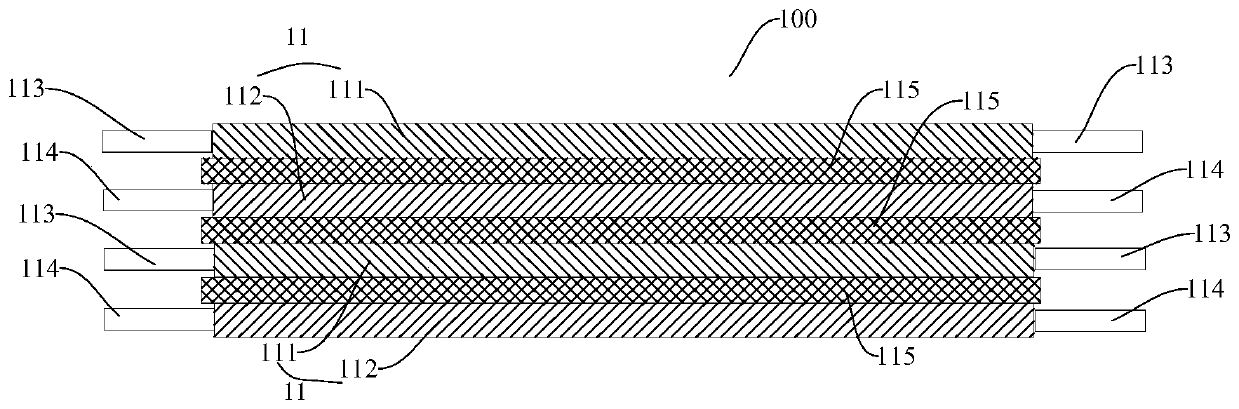

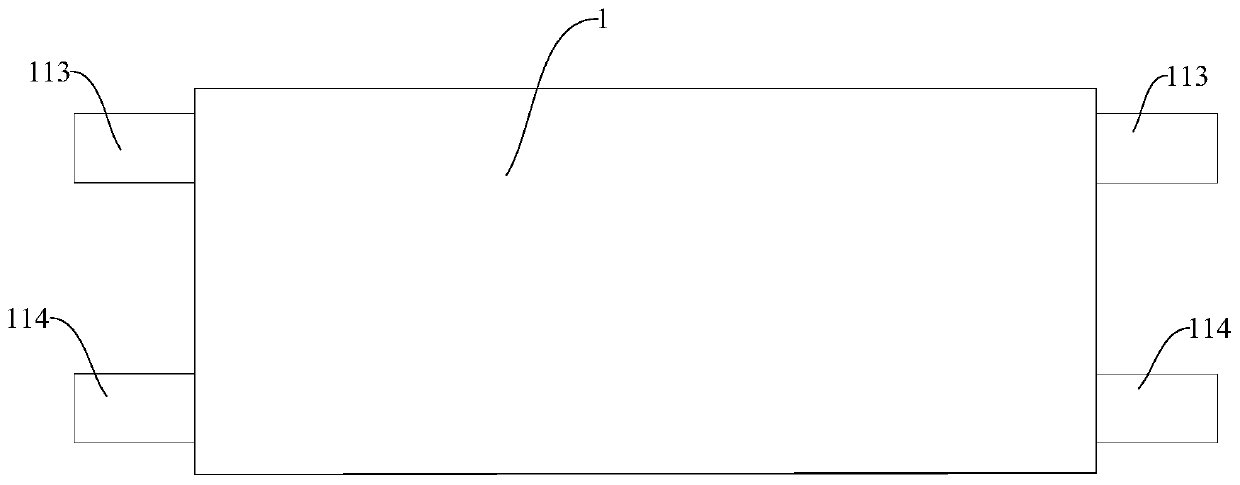

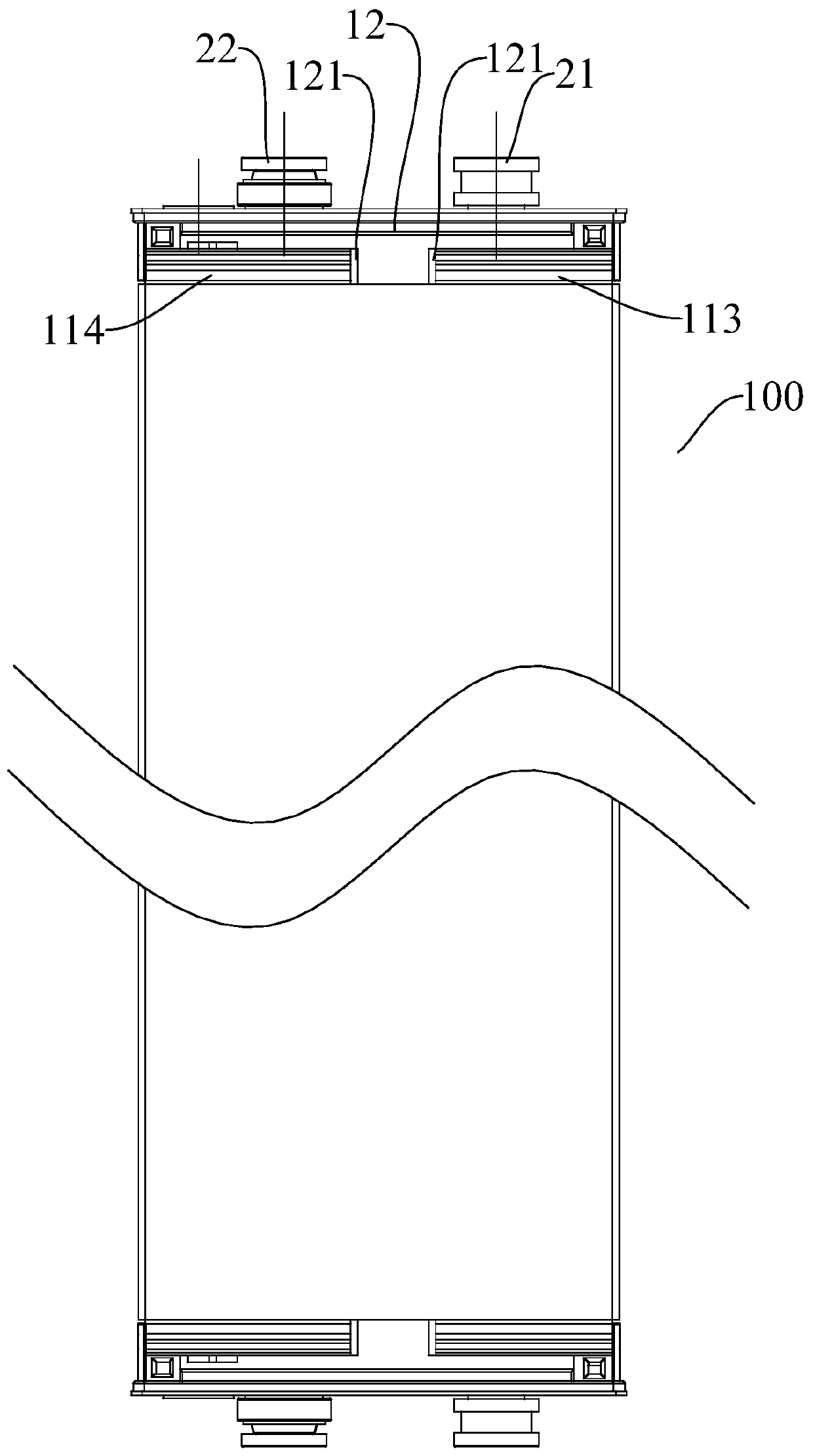

[0080] The single battery includes a shell and a pole core located in the shell. The two sides of the shell are respectively provided with electrode terminals that are electrically connected to the pole core and extend out of the shell for drawing current. The electrode terminals on each side are Two; there are tabs on the pole core, and the electrode terminals are electrically connected to the pole core through the tabs; H1 / H2=35%, H1 is the width of the tabs, H2 is the width of the pole piece, and the single battery is marked as S1.

Embodiment 2

[0082] Compared with Example 1, the difference is that H1 / H2=38%, and the single cell is marked as S2.

Embodiment 3

[0084] Compared with Example 1, the difference is that H1 / H2=42%, and the single cell is marked as S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com