Ultra-thin flexible electroluminescent sheet and preparation method thereof

A technology of electroluminescent layer and flexible electricity, which is applied in the field of ultra-thin flexible electroluminescent sheet and its preparation, and can solve the problem of cracking of the luminous uniformity of the electroluminescent sheet, brittle ceramic conductive layer, failure of the brittle ceramic conductive layer, etc. problem, to achieve the effect of light and thin thickness, reduce the overall thickness, and good anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

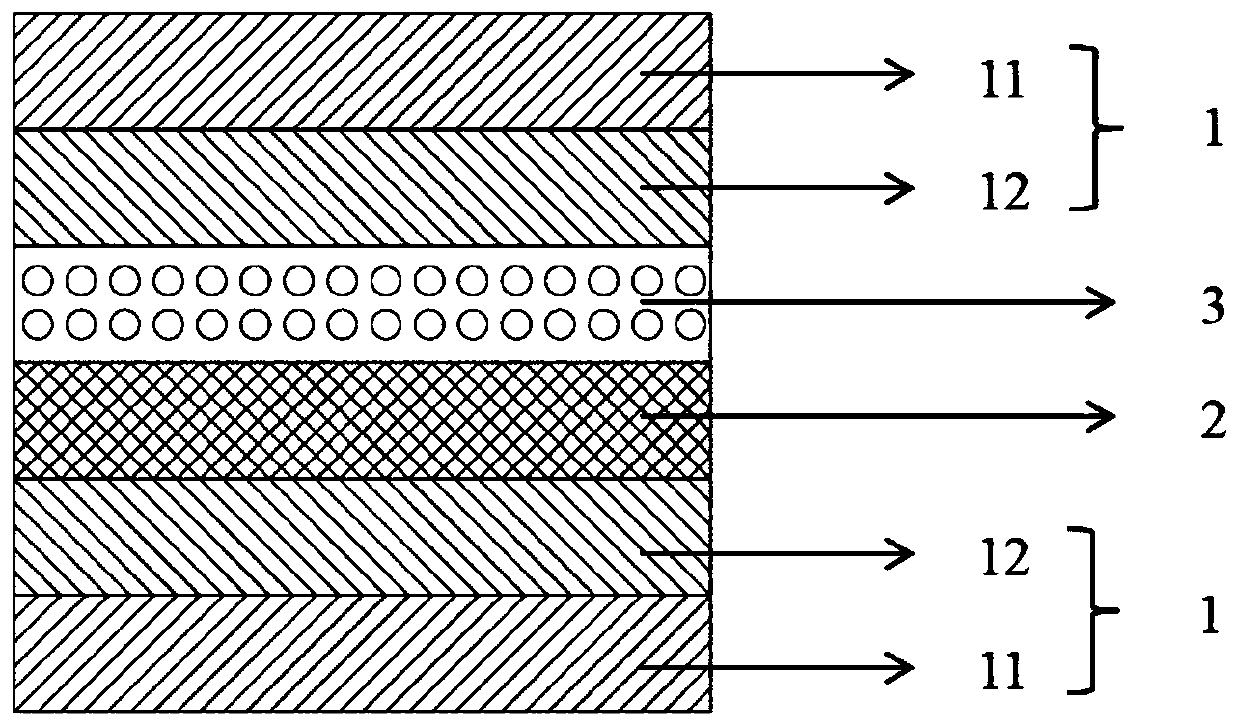

[0039] A kind of ultra-thin flexible electroluminescent sheet of the present invention, the structure of this ultra-thin flexible electroluminescent sheet is as follows figure 1 As shown, it consists of a flexible transparent electrode 1, an electroluminescent layer 2 formed by mixing nano-barium powder and water-based anionic UV glue, an insulating layer 3 prepared by water-based anionic UV glue, and a flexible transparent electrode 1. The flexible transparent electrode 1 consists of a transparent substrate 11 and a transparent conductive layer 12 from outside to inside. The transparent substrate is polyethylene terephthalate (PET), and the thickness of the transparent substrate is 15 μm; the transparent conductive layer is poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid ) (PEDOT:PSS) film, the thickness of the transparent conductive layer is 10nm, the sheet resistance of the transparent conductive layer is 300Ω / □, and the light transmittance is 95%; the quality of...

Embodiment 2

[0048] A kind of ultra-thin flexible electroluminescent sheet of the present invention, the structure of this ultra-thin flexible electroluminescent sheet is as follows figure 1 As shown, it consists of a flexible transparent electrode 1, an electroluminescent layer 2 formed by mixing nano-barium powder and water-based anionic UV glue, an insulating layer 3 prepared by water-based anionic UV glue, and a flexible transparent electrode 1. The flexible transparent electrode 1 consists of a transparent substrate 11 and a transparent conductive layer 12 from outside to inside. Wherein the transparent base material is polyimide (PI), and the thickness of the transparent base material is 50 μm; The ratio is 80%; the mass ratio of nano-barium powder to water-based anionic UV glue in the electroluminescence layer is 1:2.5.

[0049] The preparation method of the ultra-thin flexible electroluminescent sheet mainly includes the following steps:

[0050] (1) After cleaning the transparen...

Embodiment 3

[0057] A kind of ultra-thin flexible electroluminescent sheet of the present invention, the structure of this ultra-thin flexible electroluminescent sheet is as follows figure 1 As shown, it consists of a flexible transparent electrode 1, an electroluminescent layer 2 formed by mixing nano-barium powder and water-based anionic UV glue, an insulating layer 3 prepared by water-based anionic UV glue, and a flexible transparent electrode 1. The flexible transparent electrode 1 consists of a transparent substrate 11 and a transparent conductive layer 12 from outside to inside. The transparent substrate is polyethylene naphthalate (PEN), and the thickness of the transparent substrate is 50 μm; the transparent conductive layer is poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid) (PEDOT:PSS) and silver nanowires are a mixture film with a mass ratio of 1:5, the thickness of the transparent conductive layer is 50nm, the sheet resistance of the transparent conductive layer is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com