Device and method capable of automatically adding grinding fluid in grinding process

A technology of automatic adding and grinding processing, which is applied in the field of adding grinding liquid and automatic adding grinding liquid during the grinding process. It can solve the problems that the adding process cannot be automated and the grinding liquid is unevenly added manually, so as to facilitate evaluation and analysis and avoid duplication Monotonous labor, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples, but the examples are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

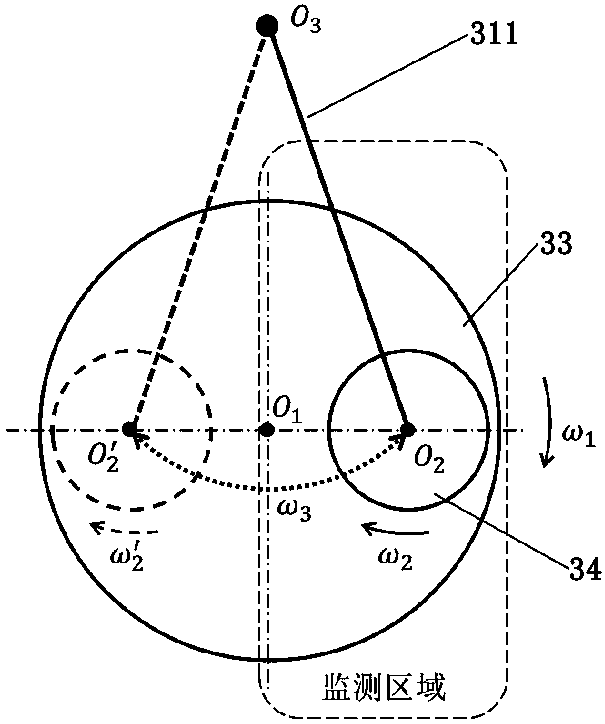

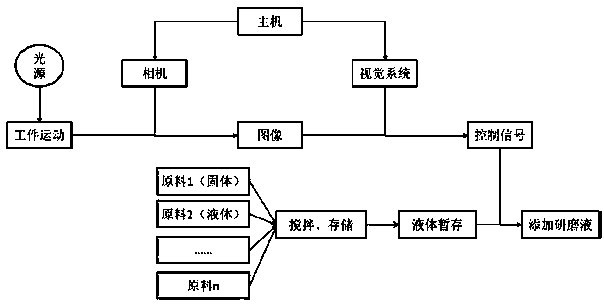

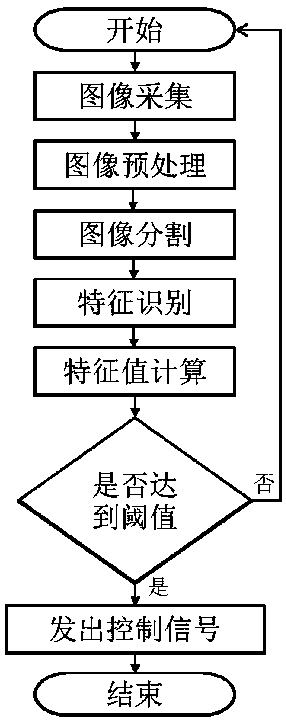

[0031] A device for automatically adding abrasive liquid during grinding process, such as Figure 5 , 6 As shown, the device includes a visual processing system 1 and a liquid adding device 2, the visual processing system 1 includes a light source 11, a camera 12, a host computer and visual processing software, and the camera 12 is fixed on the grinding and polishing machine 3 through a support 13 , the light source 11 is arranged on the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com