A method for recovering hydrogen chloride gas in the tail gas of isocyanate production by gas-phase phosgenation

A technology of hydrogen chloride gas and isocyanate, which is applied in the direction of chlorine/hydrogen chloride, chemical instruments and methods, chlorine/hydrogen chloride purification, etc., can solve problems such as low customer satisfaction, suffocation, and poor quality of takeaway hydrochloric acid, so as to reduce hidden dangers of safety accidents, Stable performance and improved permeation/separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

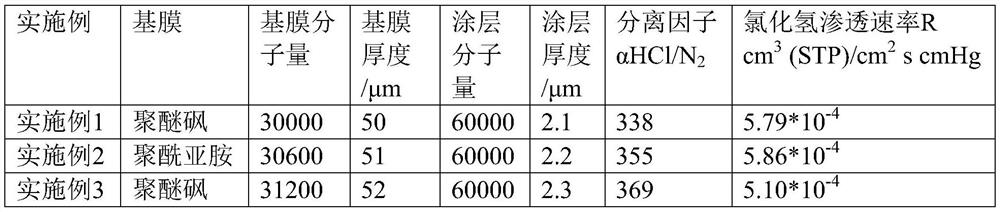

[0038] Preparation of composite membrane:

[0039] (1) Add 0.164g of azobisisobutyronitrile and 11.1g of N-vinylpyrrolidone into a three-necked flask reactor with a stirrer and a condenser, add 164g of deionized water, introduce nitrogen for 15min, and stir in a water bath at 60°C for 1 hour Afterwards, 1.21 g of benzamide was added, and the copolymer was polymerized for 7 hours to obtain a copolymer, which was dried in an oven at 60° C. for 24 hours.

[0040] (2) the copolymer after drying is purified through acetone, then heated and refluxed for 12 hours in 2.3% mass concentration of sodium hydroxide aqueous solution, and the hydrolyzate is N-vinyl-γ-aminobutyric acid sodium-sodium benzoate copolymer, The molecular weight is 60000. After cooling, filter out a small amount of suspended matter, purify with acetone, use deionized water to make an aqueous solution, and use ion exchange resin to remove residual small molecule impurities such as sodium hydroxide, and obtain 2.5% ...

Embodiment 1

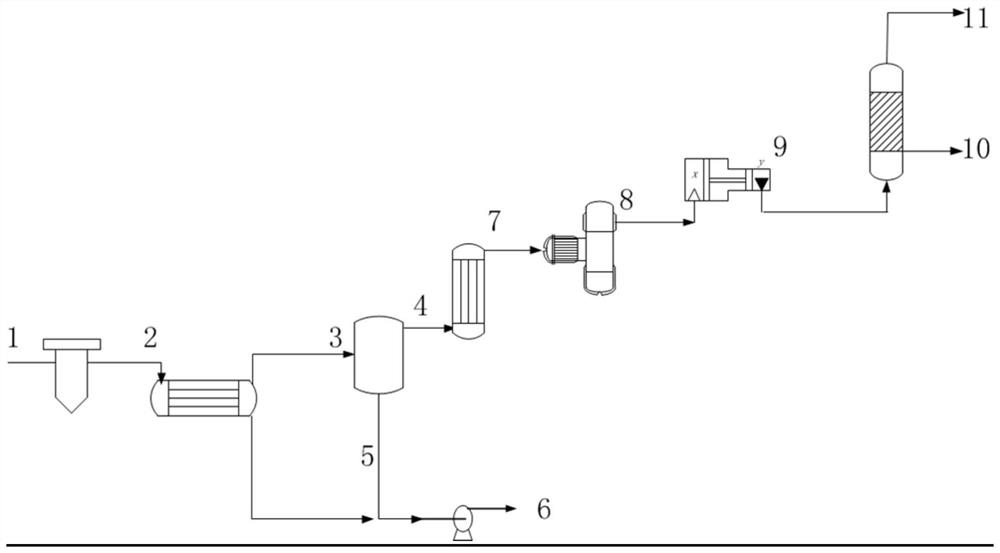

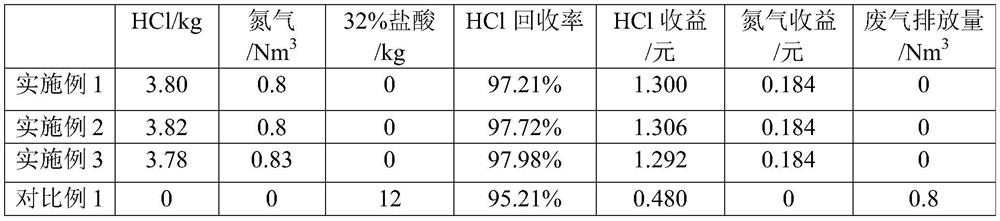

[0046] The reaction process is as figure 1 As shown in the process flow diagram, the phosgene material (mass concentration is 99%) is mixed with the hexamethylenediamine material (mass concentration is 99.9% industrial hexamethylenediamine), and the molar ratio of the two is 4:1, nitrogen and hexamethylenediamine The molar ratio of diamine is 1.33:1, and hexamethylene diisocyanate is formed by reaction at 300°C. The generated gas phase is captured by a cold solvent, and the liquid phase is sent to the downstream for refining; the tail gas generated by the reaction is condensed to remove solvent and phosgene After absorption, a mixed gas 1 containing hydrogen chloride gas and nitrogen gas is obtained, and the flow rate is 32Nm 3 / h, then the above-mentioned mixed gas 1 is filtered through a candle filter to remove solid impurities in the middle to obtain a mixed gas 2 after removal of impurities, and the solid content in the mixed gas 2 is 0.8 μg / Nm 3 . The mixed gas 2 passes...

Embodiment 2

[0048] The reaction process is as figure 1 As shown in the process flow diagram of Example 1, the same mixed gas 1 containing hydrogen chloride gas and nitrogen as in Example 1 is filtered through a candle filter to remove solid impurities in the middle to obtain mixed gas 2 after impurity removal, and the solid content in mixed gas 2 Concentration 0.8μg / Nm 3 . The mixed gas 2 passes through the Freon cryogenic heat exchanger, cools to -30°C, enters the gas-liquid separation tank 3, condenses and recovers a small amount of organic solvent, and the liquid phase organic solvent 5 is transported to the recovery system 6 through a centrifugal pump, and the gas-liquid separation The mixed gas 4 is heated, and the heated gas 7 enters the coalescing filter at 12°C to remove trace solid impurities and small liquid droplets in the gas, and then mixes the liquid and solid impurities in the non-condensable gas after being filtered by the coalescing filter Further removed to 0.08μg / Nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com